Integrated quail egg shelling separator

A quail egg and separator technology, applied in the direction of food science and the like, can solve the problems of difficulty in collecting and cleaning eggshells, inability to shell quail eggs, etc., and achieves the effect of reducing operation steps, improving practicability, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

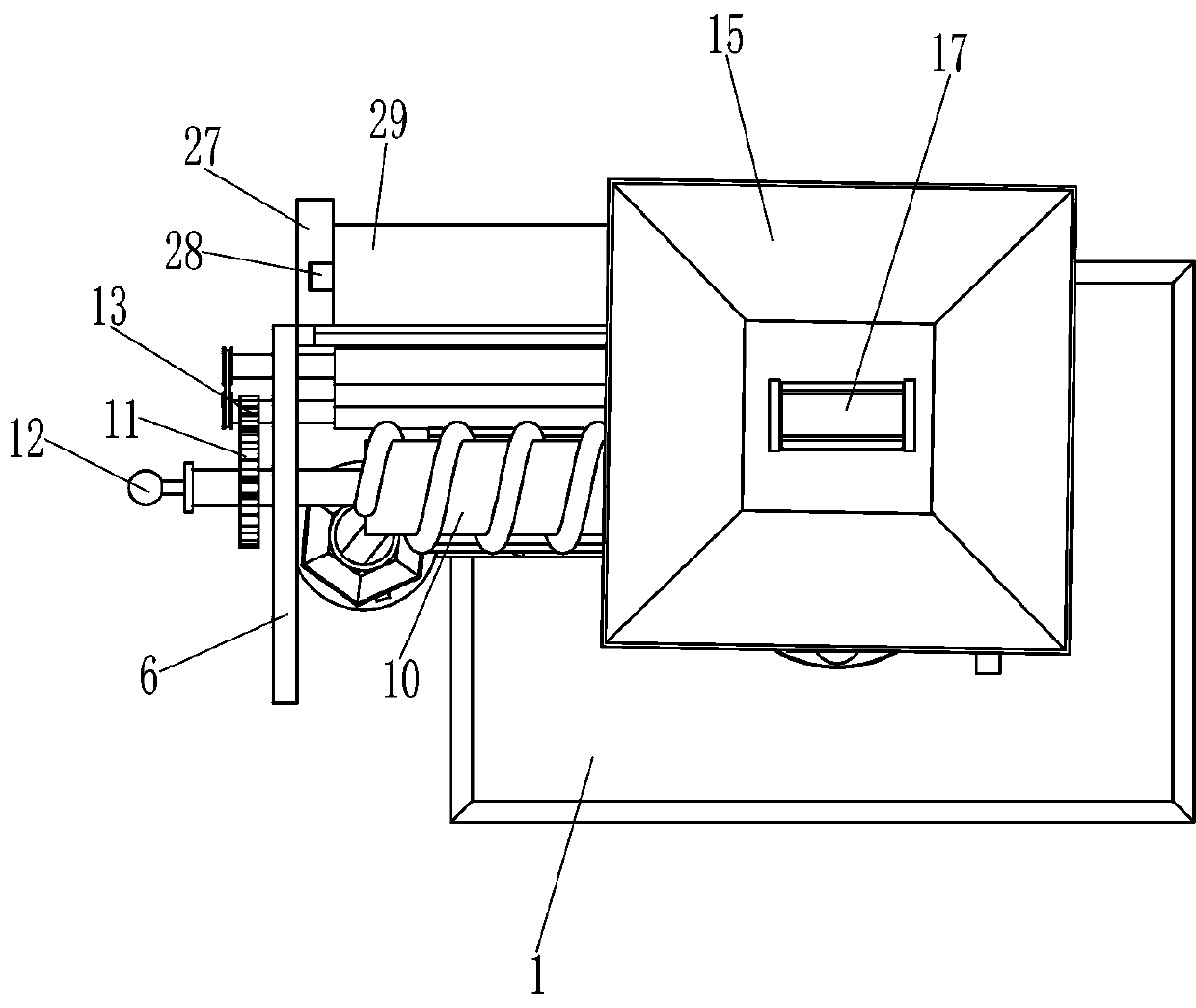

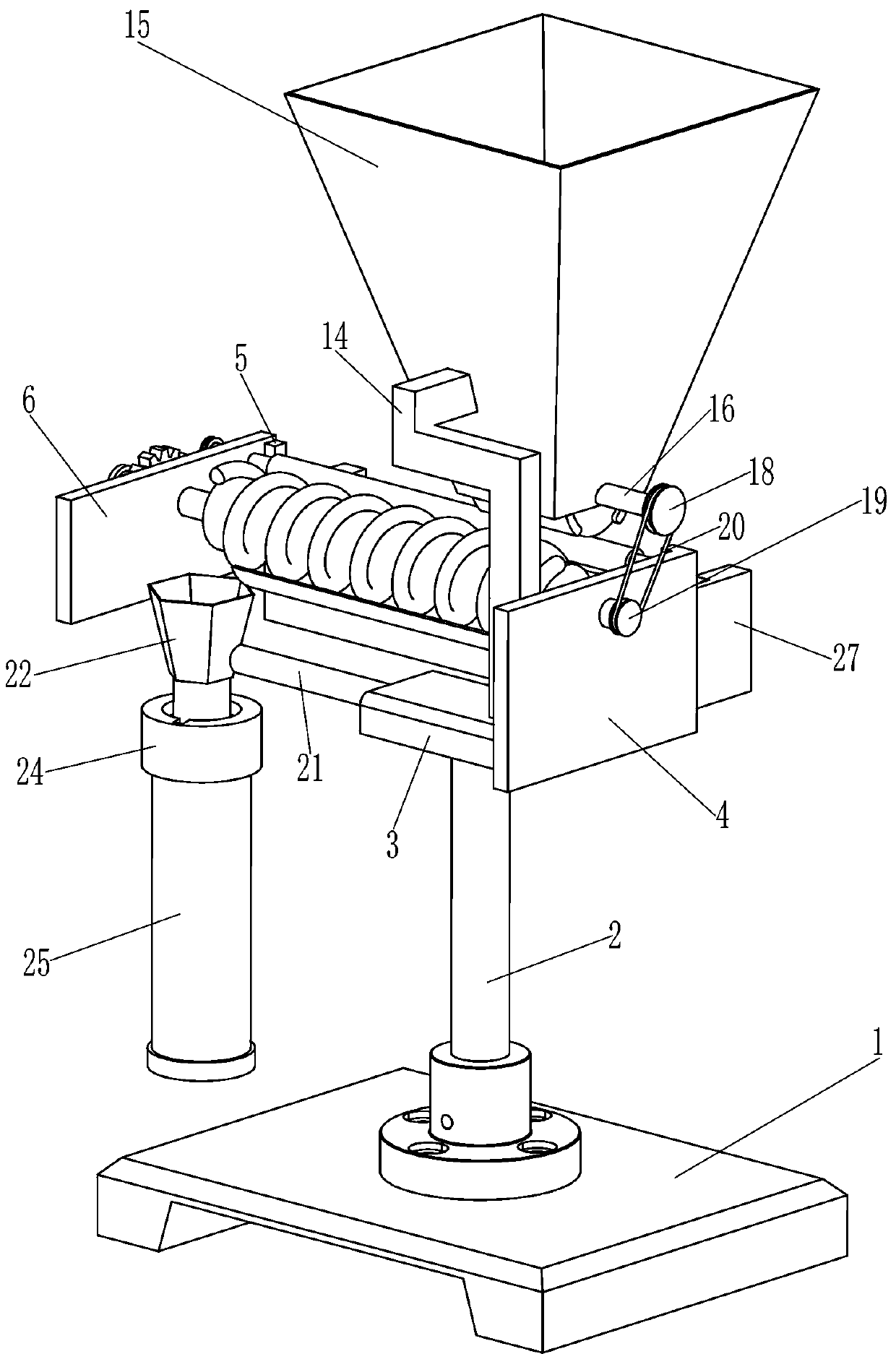

[0023] An all-in-one quail egg shelling separator, such as Figure 1-5 As shown, it includes a base 1, a support base 2, a support plate 3, a first mounting plate 4, a concave plate 5, a second mounting plate 6, a peeling roller 7, a first pulley 8, a first flat belt 9, and a push screw 10. First driving gear 11, rotating handle 12, second driving gear 13, support column 14, placement frame 15, rotating shaft 16, hopper 17, second pulley 18, third pulley 19 and second flat belt 20, base 1 The top is provided with a support seat 2, the top of the support seat 2 is provided with a support plate 3, the side of the support plate 3 is provided with a first mounting plate 4, the first mounting plate 4 is provided with a concave plate 5, and one side of the concave plate 5 A second mounting plate 6 is provided, and a peeling roller 7 is connected in a distributed stepped rotation between the second mounting plate 6 and the first mounting plate 4. One side of the peeling roller 7 is p...

Embodiment 2

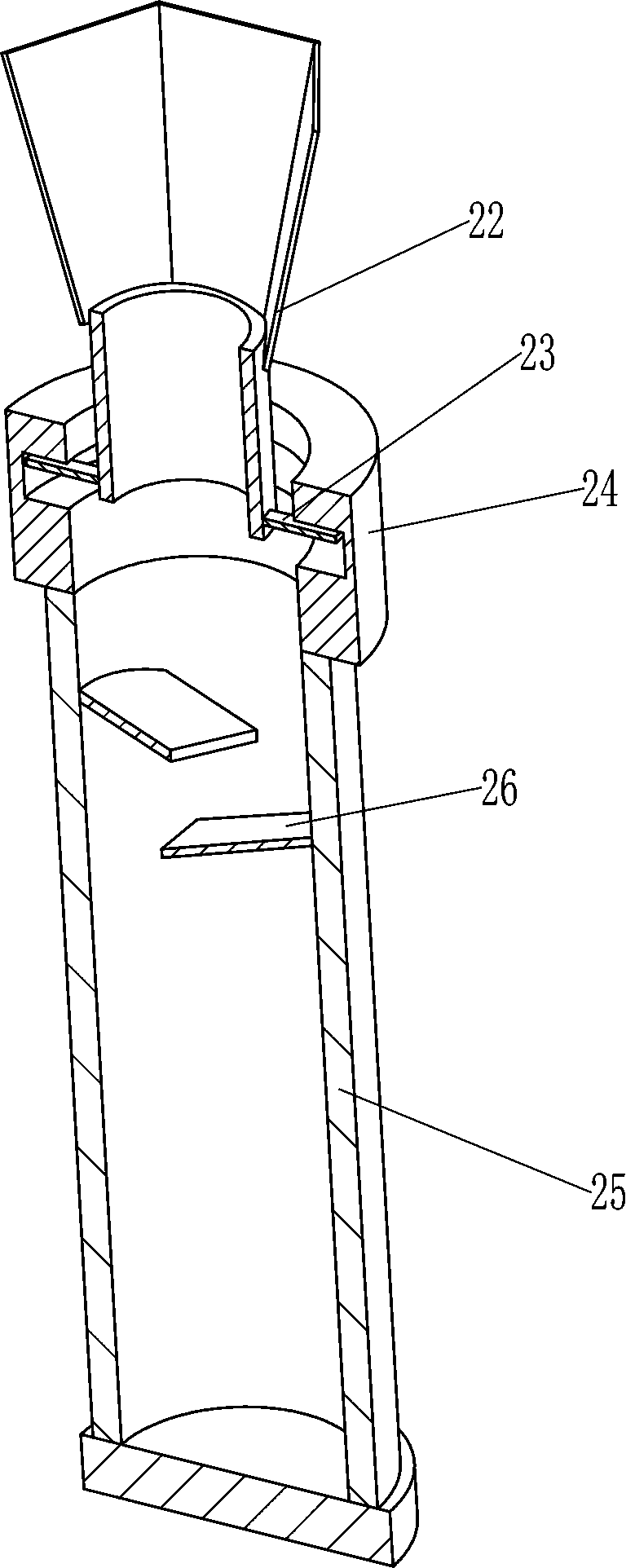

[0026] On the basis of Example 1, such as figure 1 and Figure 5 As shown, it also includes a pole 21, a receiving hopper 22, a placement piece 23, an annular slotted disc 24, a material receiving tank 25 and a buffer plate 26, one side of the support plate 3 is provided with a pole 21, and one end of the pole 21 is provided with a Receiving hopper 22, both sides of receiving hopper 22 are provided with placing piece 23, placing piece 23 top is placed with annular slotted disc 24, annular slotted disc 24 bottom is provided with material receiving tank 25, and inside receiving tank 25 is inclined to be provided with cushioning plate 26.

[0027] When the shelled quail eggs fall from the equipment, the quail eggs will fall into the receiving tank 25 after passing through the receiving hopper 22 and the buffer plate 26 in turn. Through the buffer plate 26, the quail eggs will be effectively reduced. The impact force of the quail eggs has ensured the integrity of the quail eggs ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap