Material packaging machine

A material bag and rack technology, applied in the field of instant noodle machine, can solve the problems of single nutrition, impact on the environment, easy to break, etc., and achieve the effect of meeting the needs of diners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

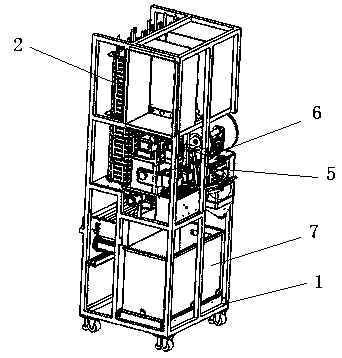

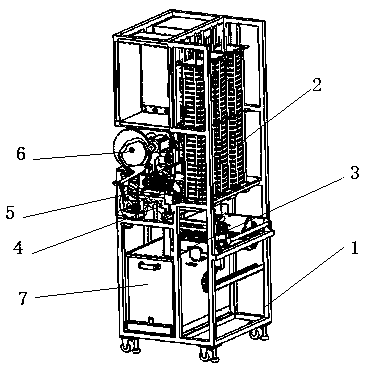

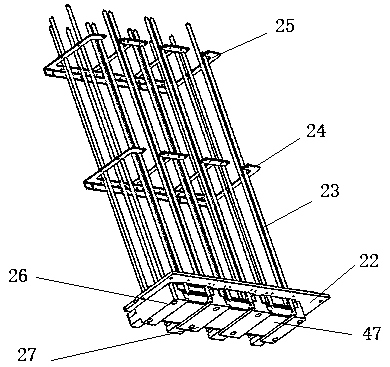

[0034] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as Figure 1-Figure 8 , the column 61 in this example is a cylinder made of round steel, the lower end of the column 61 is installed on the frame 1, fixedly connected with the frame 1, and the upper end is connected with the support plate 607; The general-purpose spur gear is used as the driving gear 62, and the described material bag turning driving gear 62 is installed on the frame 1 through the bearing seat, and is fixedly connected with the frame 1 through the bearing shaft and the bearing, so that it can be mounted on the frame 1. Rotate upwards, the teeth of the two bag turning drive gears 62 mesh with each other; the bag turning swing lever 63 is installed on one of the outer surfaces of the two bag turning driving gears 62, and can be turned over and driven with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com