Method for attaching label

A labeling and attaching technology, which is applied in the direction of labels, labeling machines, packaging, etc., to achieve the effect of accurate labeling position, improved exhaust mode, and reduced air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0017] A label attachment method of the present invention comprises the following steps:

[0018] Step 1: Labeling processing steps

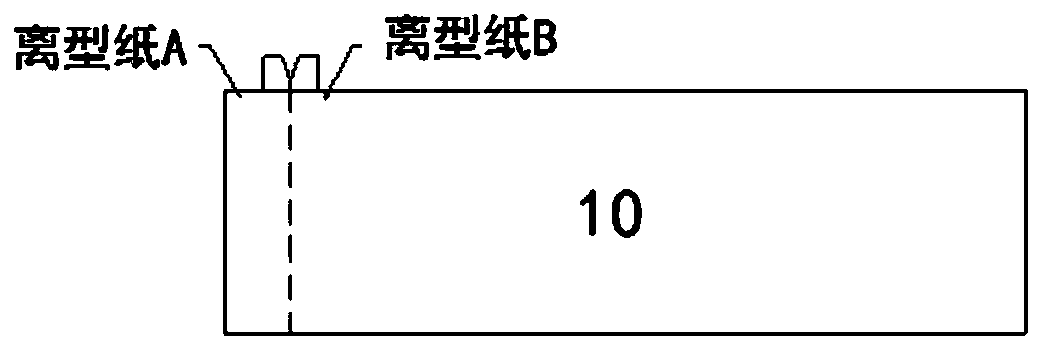

[0019] see figure 1 , cutting the entire release paper of the large-size label 10 into two sections, which are release paper A and release paper B, wherein the area of release paper A is much smaller than the area of release paper B;

[0020] Step 2: Fixing the label position

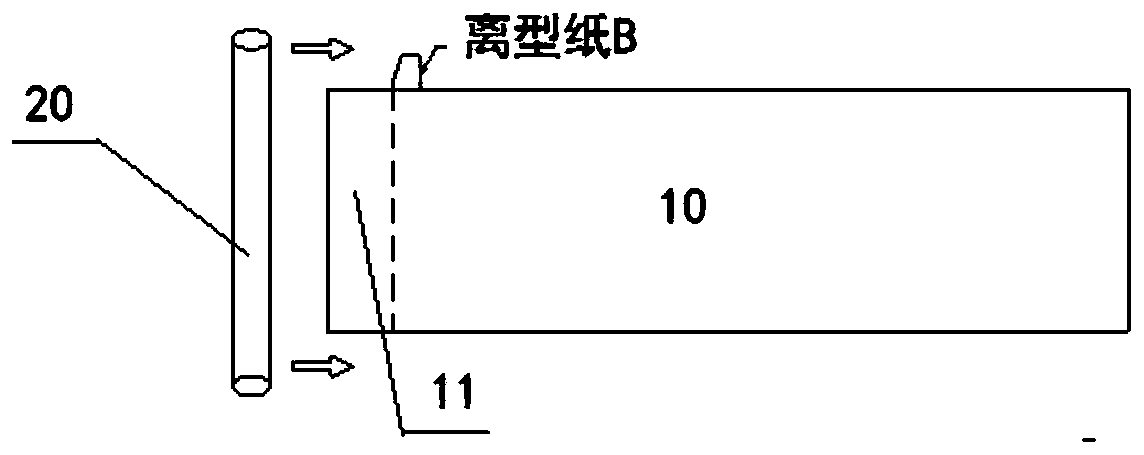

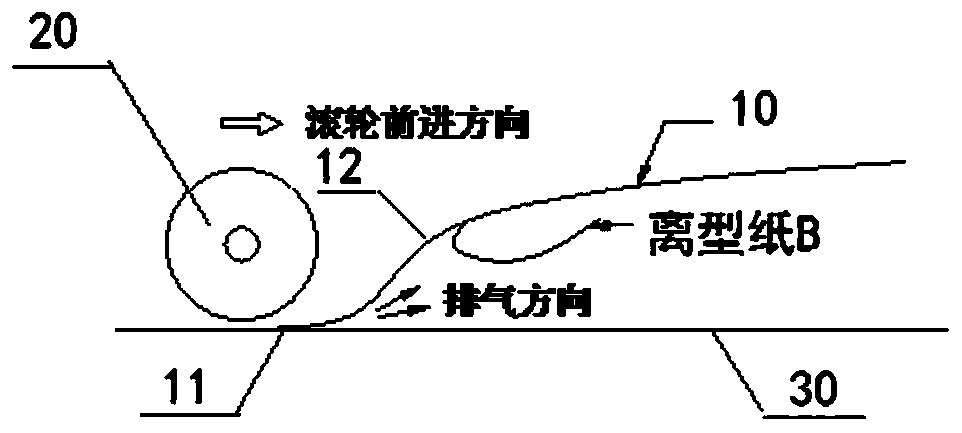

[0021] see figure 2 , before sticking, tear off the release paper A, at this time, the area 11 where the label is torn off the release paper A is in a sticky state, and then the area 11 where the label is torn off the release paper A is placed on the object 30 (see image 3 ), after calibrating the position, press the area 11 where the label is torn off the release paper A to fix the position of the label 10;

[0022] Step 3: Lab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com