Photochromic stone-like coating for building external walls

A technology for building exterior walls and causing discoloration, which is applied in the field of architectural coatings and paints, and can solve problems such as low binding force, complexity, and harsh outdoor environments, and achieve a long-lasting effect of discoloration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

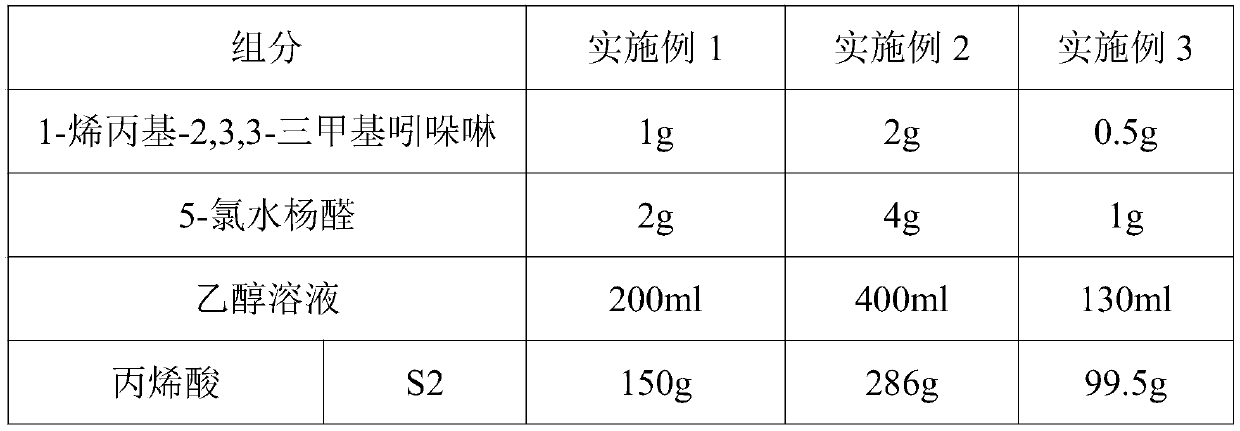

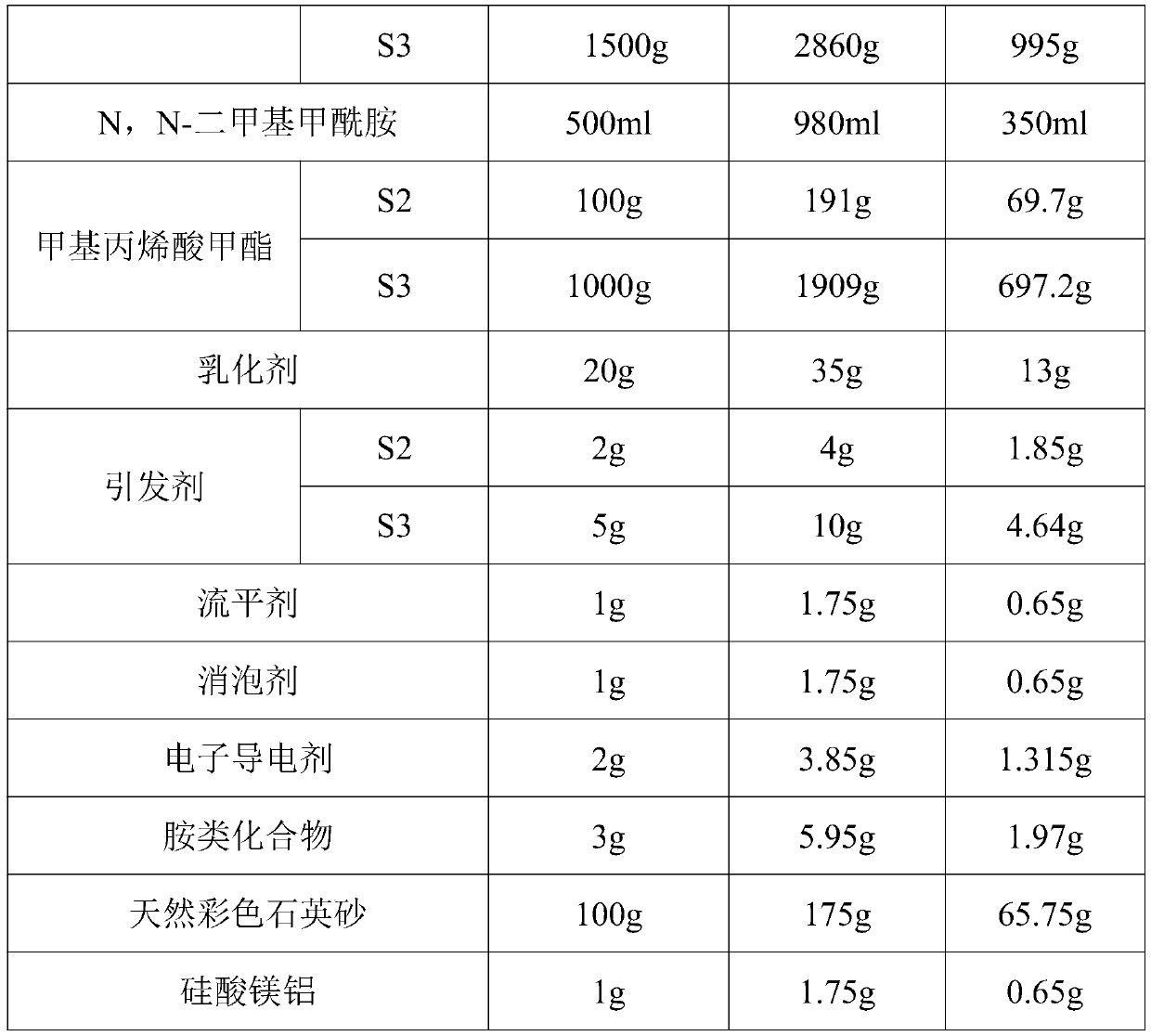

[0009] Embodiment 1-3 provides a kind of photochromic real stone paint coating for building exterior wall, and wherein the component of color-changing architectural coating and content thereof are as shown in Table 1:

[0010] Components and content thereof of table 1 embodiment 1-3 color-changing architectural coatings

[0011]

[0012]

[0013] The preparation method of above-mentioned photochromic real stone paint coating specifically comprises the following steps:

[0014] S1. Preparation of small molecule compounds with photochromic functional groups: Mix 1-allyl-2,3,3-trimethylindoline and 5-chlorosalicylaldehyde in ethanol solution, react The temperature was 60° C. and refluxed for 6 hours to finally generate 1-allyl-6-chlorospiro[2H-1-benzopyran-2,2′-indoline].

[0015] S2, emulsion polymerization prepares photochromic pure acrylic emulsion: methyl methacrylate, acrylic acid, initiator (benzoyl peroxide) and N, N-dimethylformamide, 1-allyl-6-chloro Spiro[2H-1-b...

Embodiment 2

[0019] The defoamer in Example 2 is aliphatic defoamer; the electronic conductive agent is polypyrrole; the amine compound is ammonia water.

Embodiment 3

[0020] The defoamer in Example 3 is simethicone; the electronic conductive agent is polypyrrole; the amine compound is a mixture of ammonium bicarbonate and ammonium chloride.

[0021] In order to further illustrate the beneficial effects of the present invention, the photochromic real stone paint coating prepared in Example 1 of the present invention is selected, according to the JB / T9327-1999 whiteness meter standard. Coat the prepared photochromic real stone paint on a polytetrafluoroethylene board, air-dry to form a film with a film thickness of 1mm, and irradiate it with ultraviolet light with a wavelength of 280nm-350nm for 5 minutes, and immediately use a whiteness meter (WSB- 2) To test the whiteness, remove the ultraviolet light for 5 minutes and then test the whiteness value. Table 2 shows the change of whiteness.

[0022] Table 2 Changes in whiteness under different lighting conditions

[0023] Lighting time 0 minutes 5 minutes 5 minutes after remova...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap