Intercepting device and using method, and pipeline for installing intercepting device

A shut-off device and pipeline technology, applied in the direction of valve devices, measuring devices, water supply devices, etc., can solve the problems of poor sealing, inability and large deformation of the pressurized cavity, and achieve simple structure, good sealing effect, and tight sealing The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

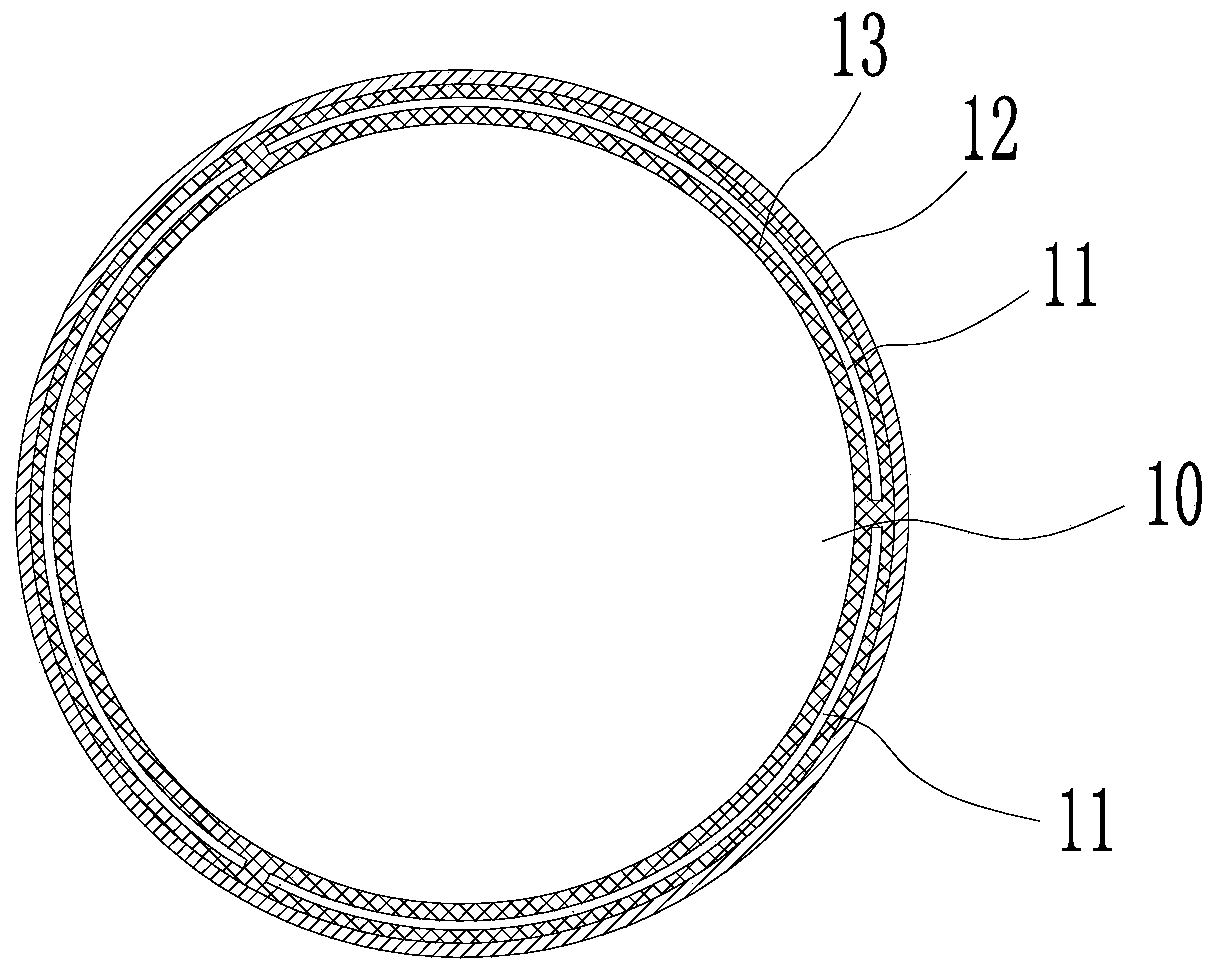

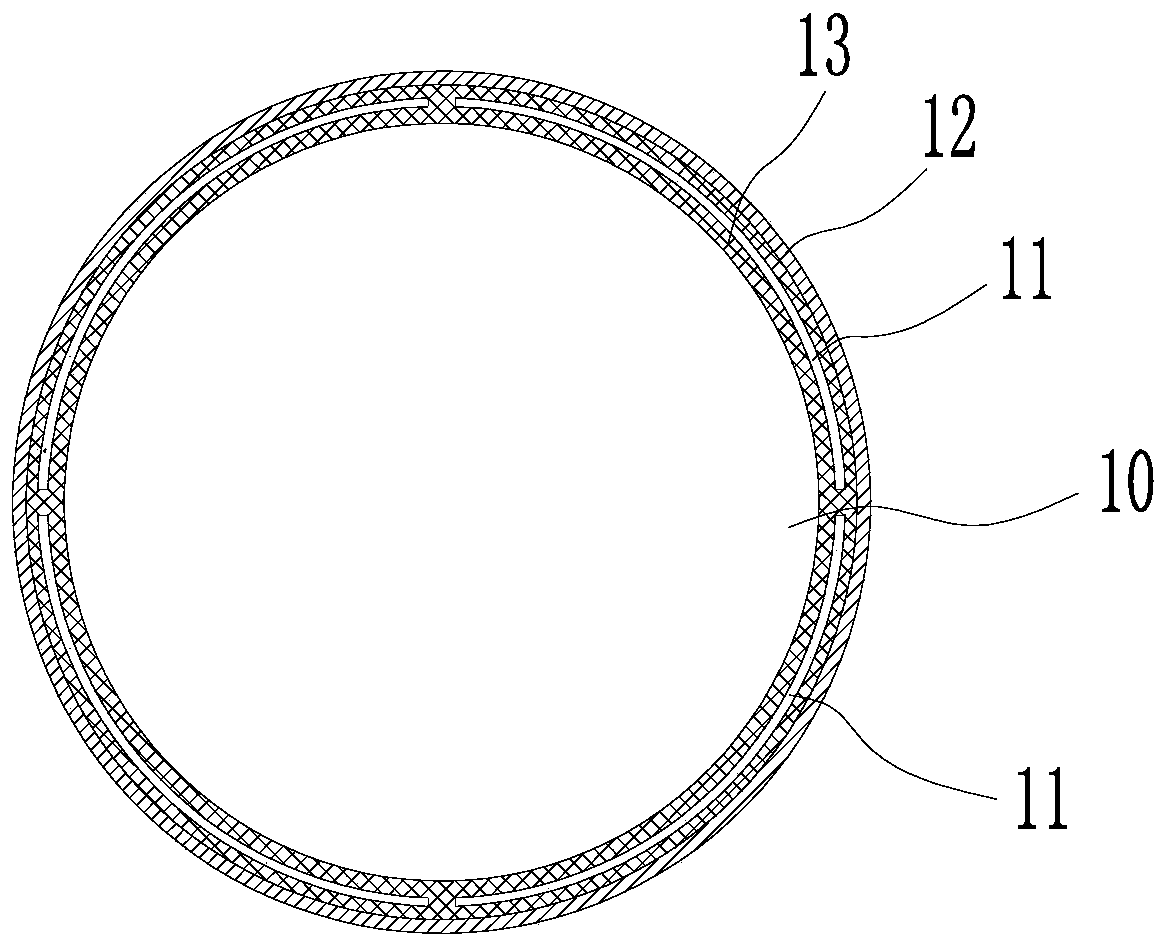

[0032] see Figure 1 to Figure 9 As shown, the present invention provides a shut-off device, including a rubber sleeve 1, the rubber sleeve 1 is provided with a through flow channel 10, and three or four independent pressure chambers 11 are arranged in the inner circumference of the rubber sleeve 1. In the example, the rubber sleeve 1 is cylindrical, and the cross-sectional shape of the rubber sleeve 1 is circular, and the rubber sleeve 1 at the position of each pressure chamber 11 has an outer rubber layer 12 and an inner rubber layer 13, and The outer rubber layer 12, the inner rubber layer 13 and the rubber sleeve 1 outside the pressure chamber 11 are in an integrated structure; the outer rubber layer 12 of each pressure chamber 1 is provided with an inlet and outlet hole 14, and the inlet and outlet holes 14 and The pressurized chamber 11 is communicated, and the inlet and outlet holes 14 can be two holes of the inlet hole and the outlet hole arranged on the outer rubber l...

Embodiment 2

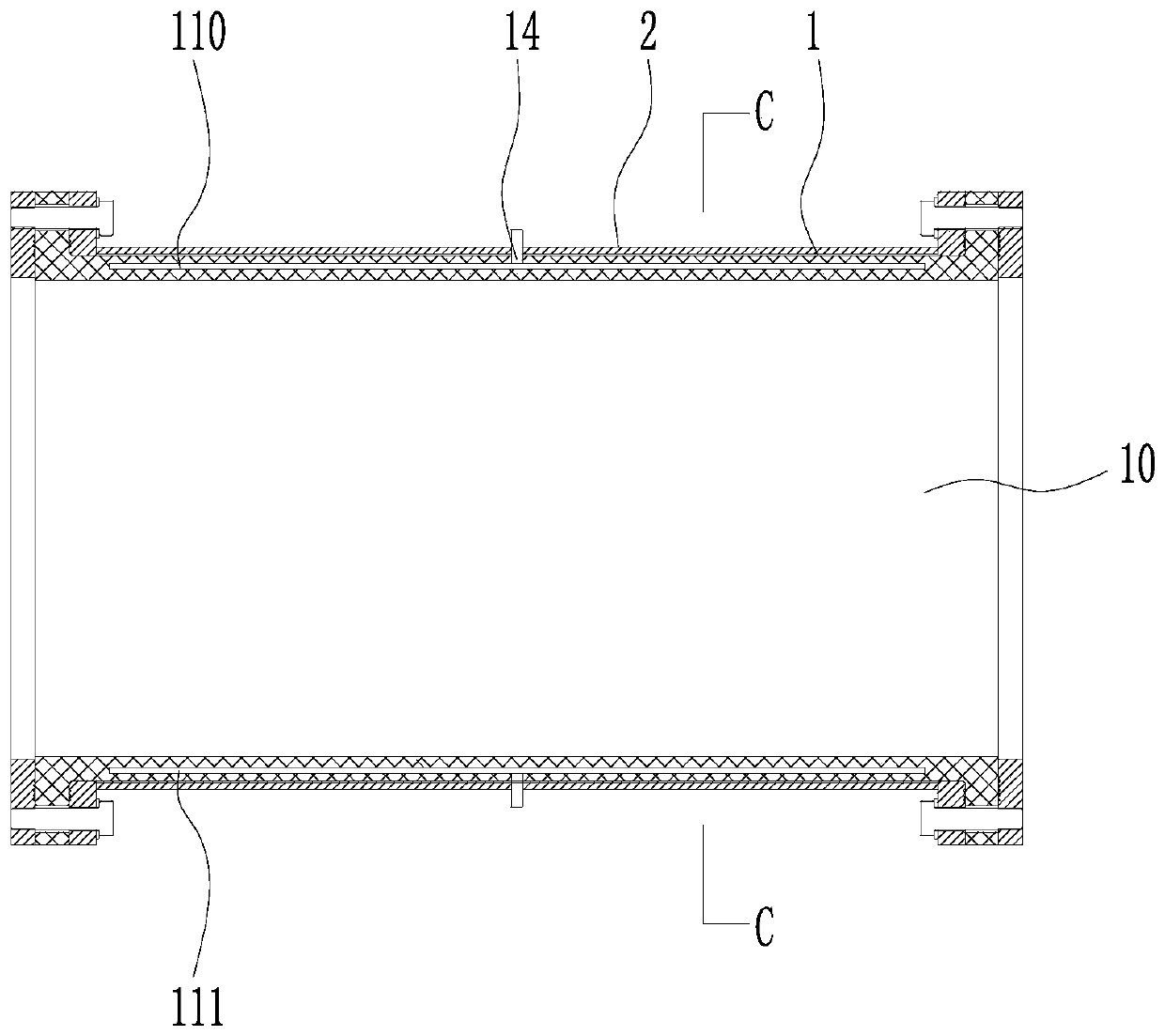

[0038] see Figure 9 As shown, this embodiment also provides a pipeline with a shut-off device, including:

[0039] The intercepting device in this embodiment, the intercepting device includes a rubber sleeve 1;

[0040] Gland 4, one end of the rubber sleeve 1 is provided with a circumferentially outward raised edge, the other end of the rubber sleeve 1 is installed in the pipe, and the outer wall of the rubber sleeve 1 is attached to the inner wall of the pipe, and the raised edge passes through the The gland 4 is fitted and fixed around the pipe port. During installation, the rubber sleeve 1 is inserted into the pipe from the pipe port, and the raised edge of the rubber sleeve 1 is fixed around the pipe port by the gland 4 and bolts. Easy to install and disassemble. The rubber sleeve 1 is fixed in the pipe through the gland, which cancels the structure of the traditional steel outer cover and reduces the weight of the whole product. At the same time, due to the removal of ...

Embodiment 3

[0046] This embodiment also provides a method for using the intercepting device, as follows:

[0047] Install the shut-off device with four independent pressurized chambers 11 in the pipeline in Example 1. In the installed state, two pressurized chambers 11 are located in the lower half of the pipeline, and the other two pressurized chambers 11 are located in the upper half of the pipeline. The device includes Cut-off state and cut-off state, choose the following cut-off state or cut-off state according to the use requirements:

[0048] At the same time, fill the two pressure chambers 11 located in the lower half with a certain pressure medium until the inner rubber layers of the two pressure chambers 11 are bonded together, and the inner rubber layer 13 of the two pressure chambers 111 deforms upwards to have a certain flow rate Highly see Figure 4 As shown, the flow passage 10 is in a shut-off state;

[0049] All the pressure chambers of the simple shut-off device are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com