Plasma reaction chamber structure with adjustable radio frequency coil

A plasma and reaction chamber technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of inability to form a circular RF coil shape, affecting plasma distribution and stability, and easy deformation of RF coils.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

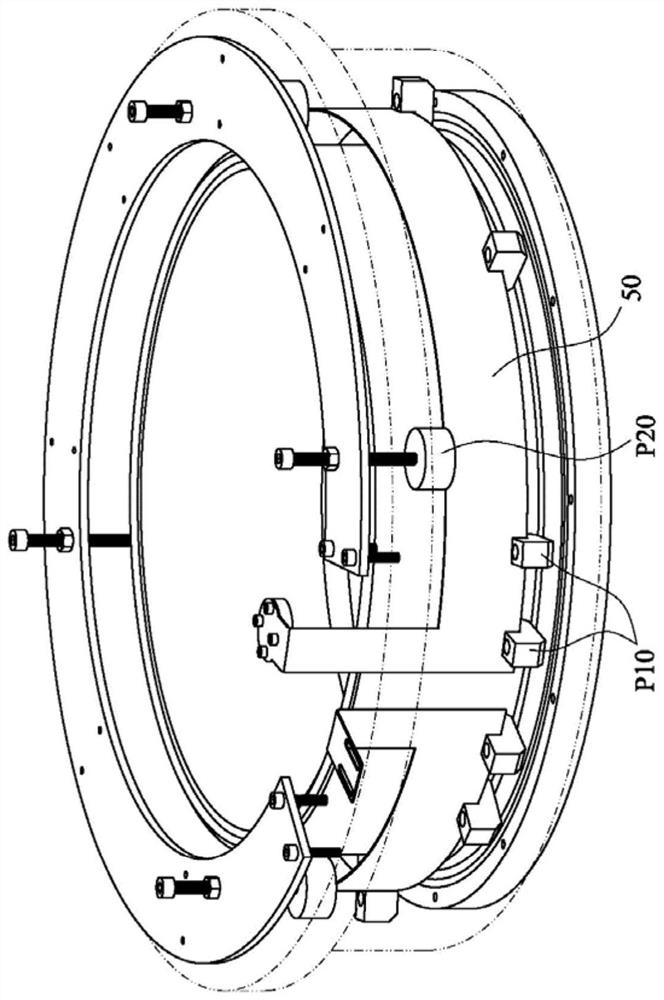

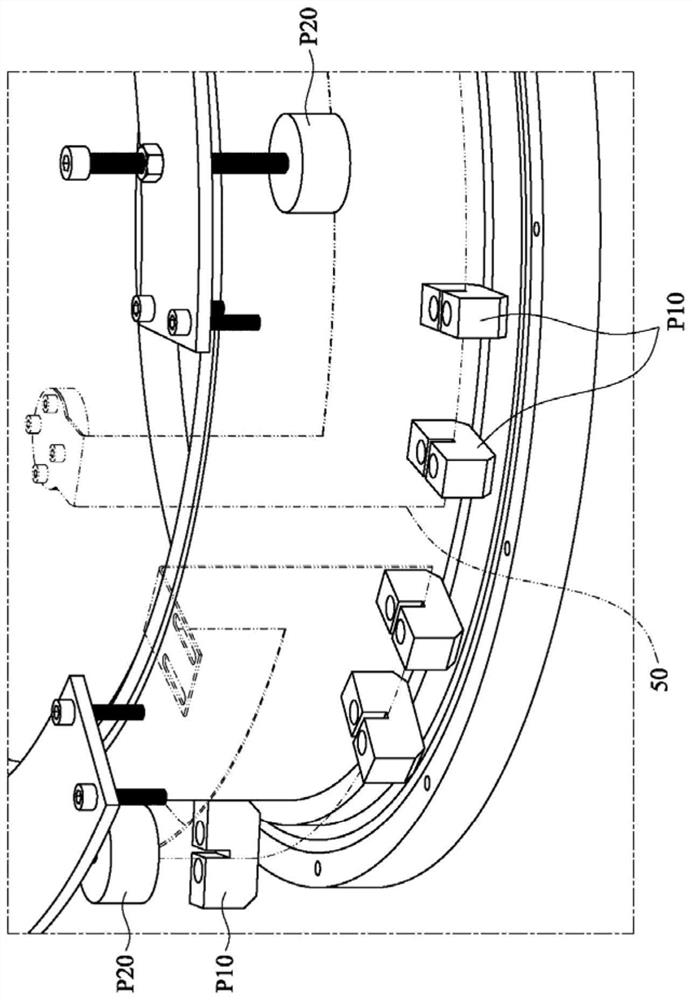

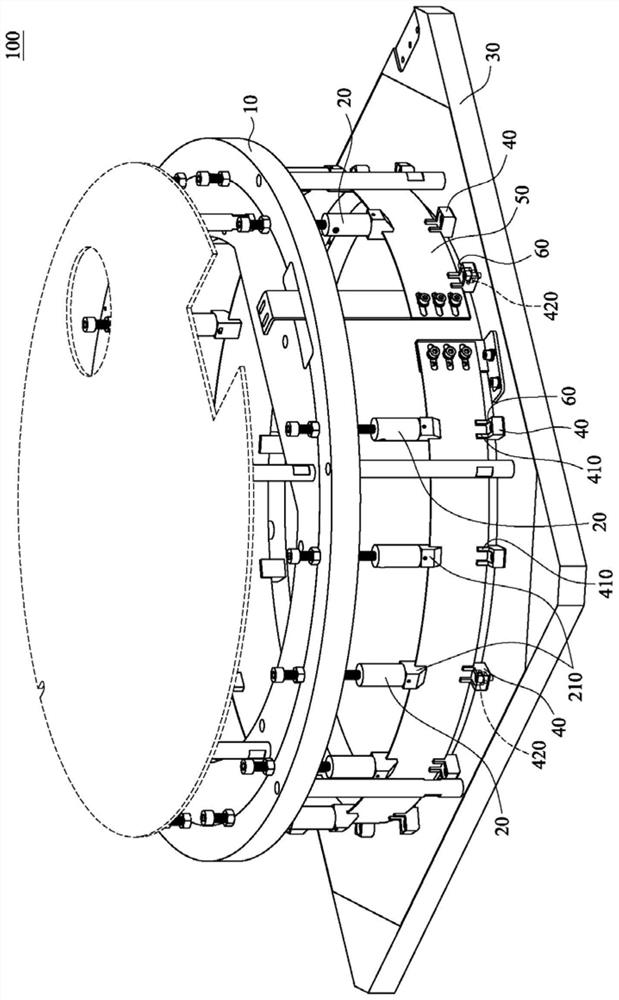

[0065] like 2A to 2E As shown, the first embodiment is a plasma reaction chamber structure 100 with an adjustable radio frequency coil, which includes: an upper support 10; a plurality of clamping bolts 20; a lower support 30; a plurality of continuous sliding clamping 40; and the radio frequency coil 50.

[0066] The upper support 10 is a structural support member of the plasma reaction chamber structure.

[0067] like Figure 2C As shown, a plurality of clamping bolts 20 are combined with the upper support 10 to adjust the lifting height, and in order to adjust the radio frequency coil 50 more accurately, elastically, conveniently and effectively, each clamping bolt 20 is a The upper clamping part 210 can be continuously slidable.

[0068] The continuity referred to in this embodiment means that it is not limited by the distance of the first order and the first order, and can be a movement of any distance, for example: 0.5 cm, 0.01 cm, 0.003 cm, 0.N cm, etc. There is no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com