Method of assembling curved display devices

A display device, curved technology, applied in the direction of chemical instruments and methods, metal layered products, synthetic resin layered products, etc., can solve the problem of reduced viewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

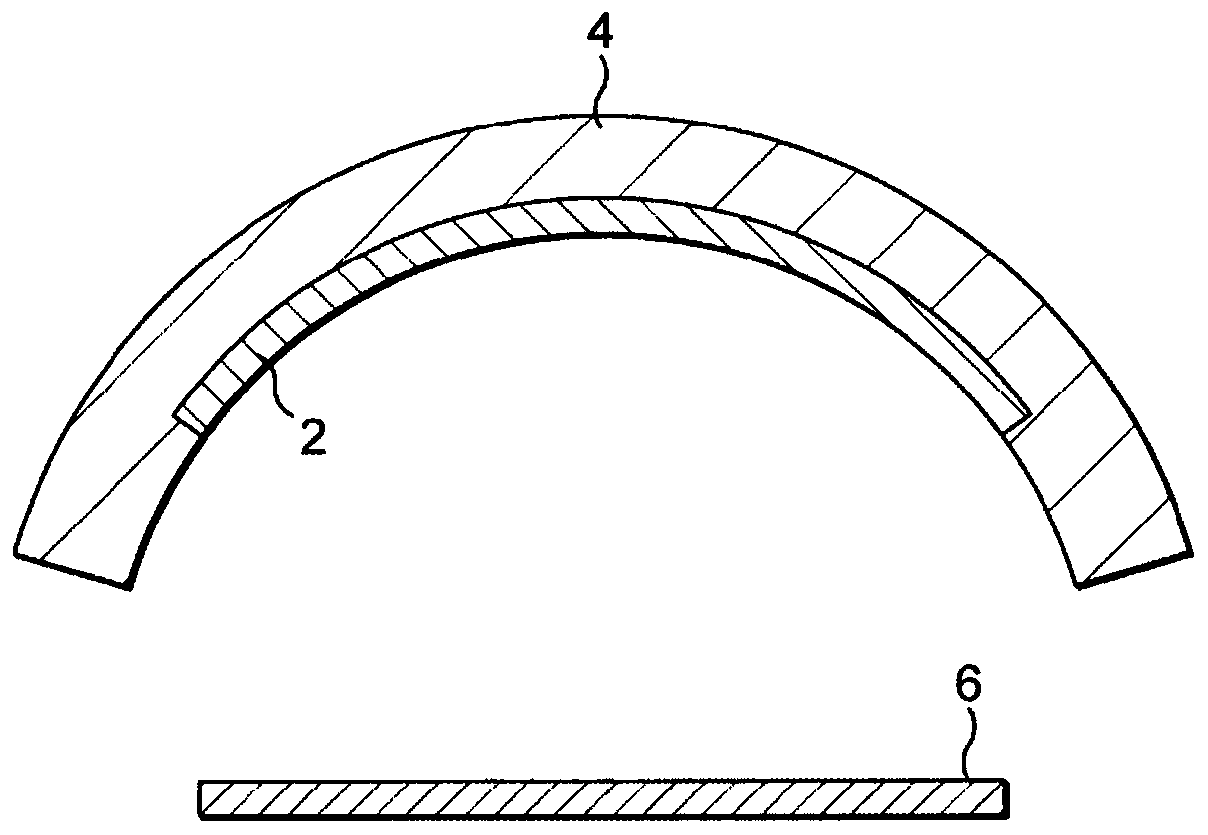

[0026] The examples detailed below refer to the production of LCD display devices, but the same techniques can also be used to produce LED display devices (e.g., organic light emitting diode (OLED) devices), which can include light emitting components (including light emitting materials and control circuits) and a plurality of individual components of one or more circular polarizer components, touch sensor components and one or more packaging films.

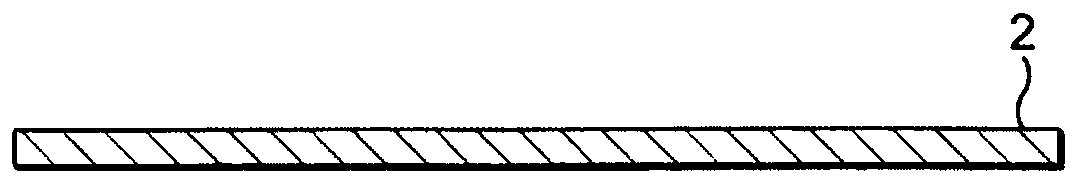

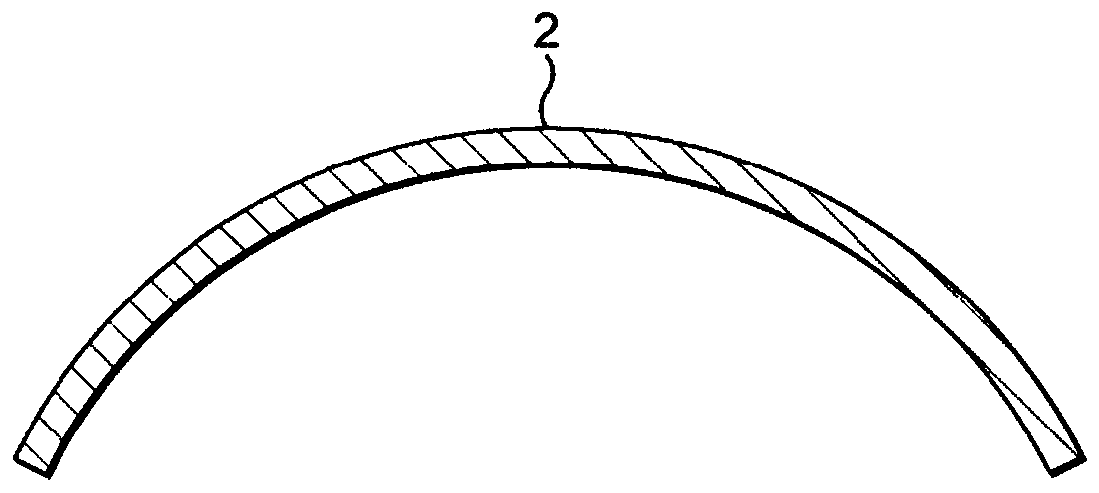

[0027] The example technique described below relates to the production of a display device in which the convex surface of the curved window / cover assembly 2 forms the viewing exterior surface of the display device. However, the same technology can also be applied to display devices with other forms.

[0028] Again, the example techniques described below relate to the production of display devices with relatively simple curved forms (having a single axis of curvature), but the same techniques are equally applicable to display devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap