Omnibearing aluminium profile automatic spraying detecting device

A spraying device and automatic detection technology, which is applied in the direction of spraying devices, measuring devices, instruments, etc., can solve the problems of lack of detection devices, cumbersome steps, and uneven paint surface on the surface of aluminum plates, so as to improve production efficiency and reduce labor intensity , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

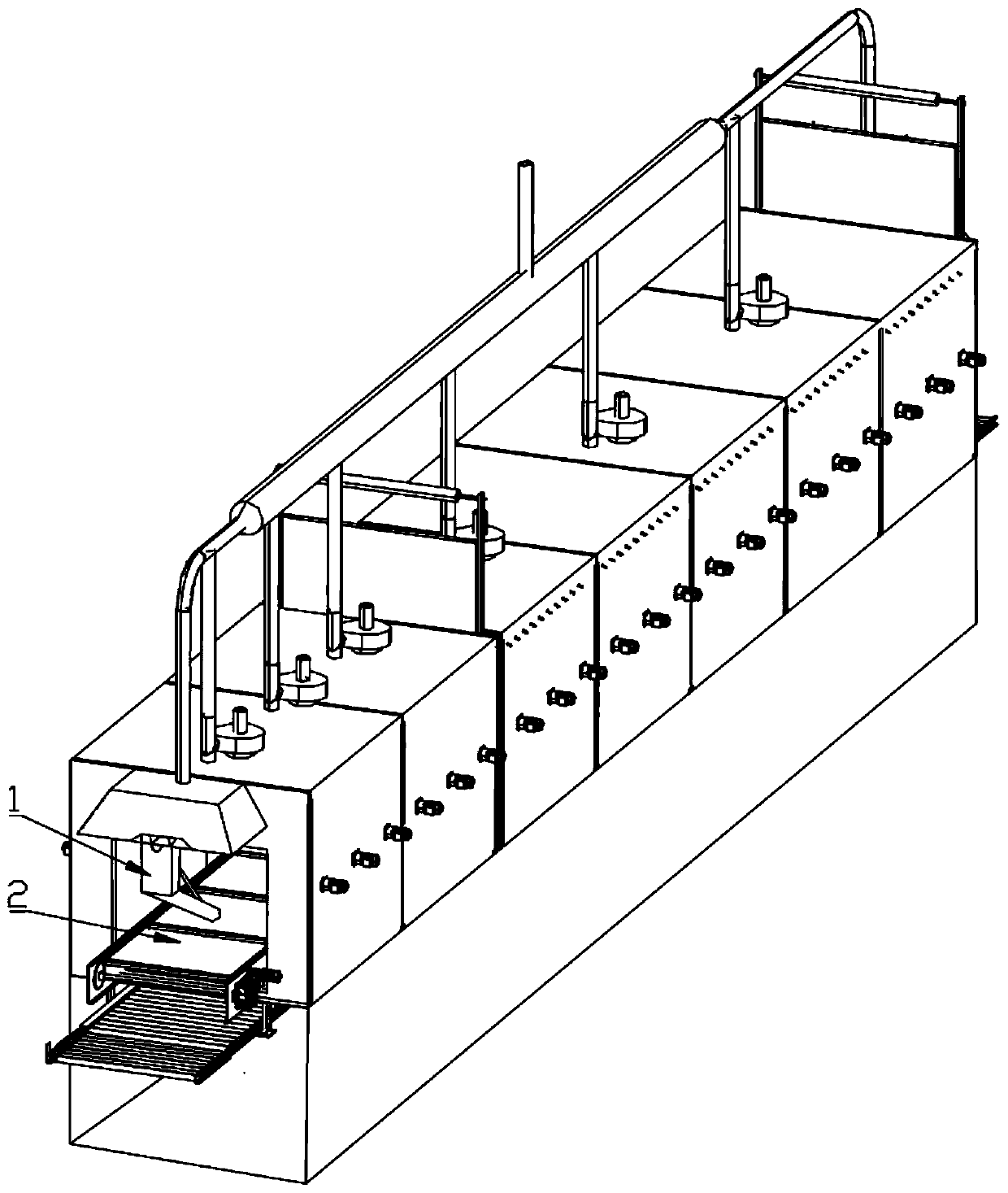

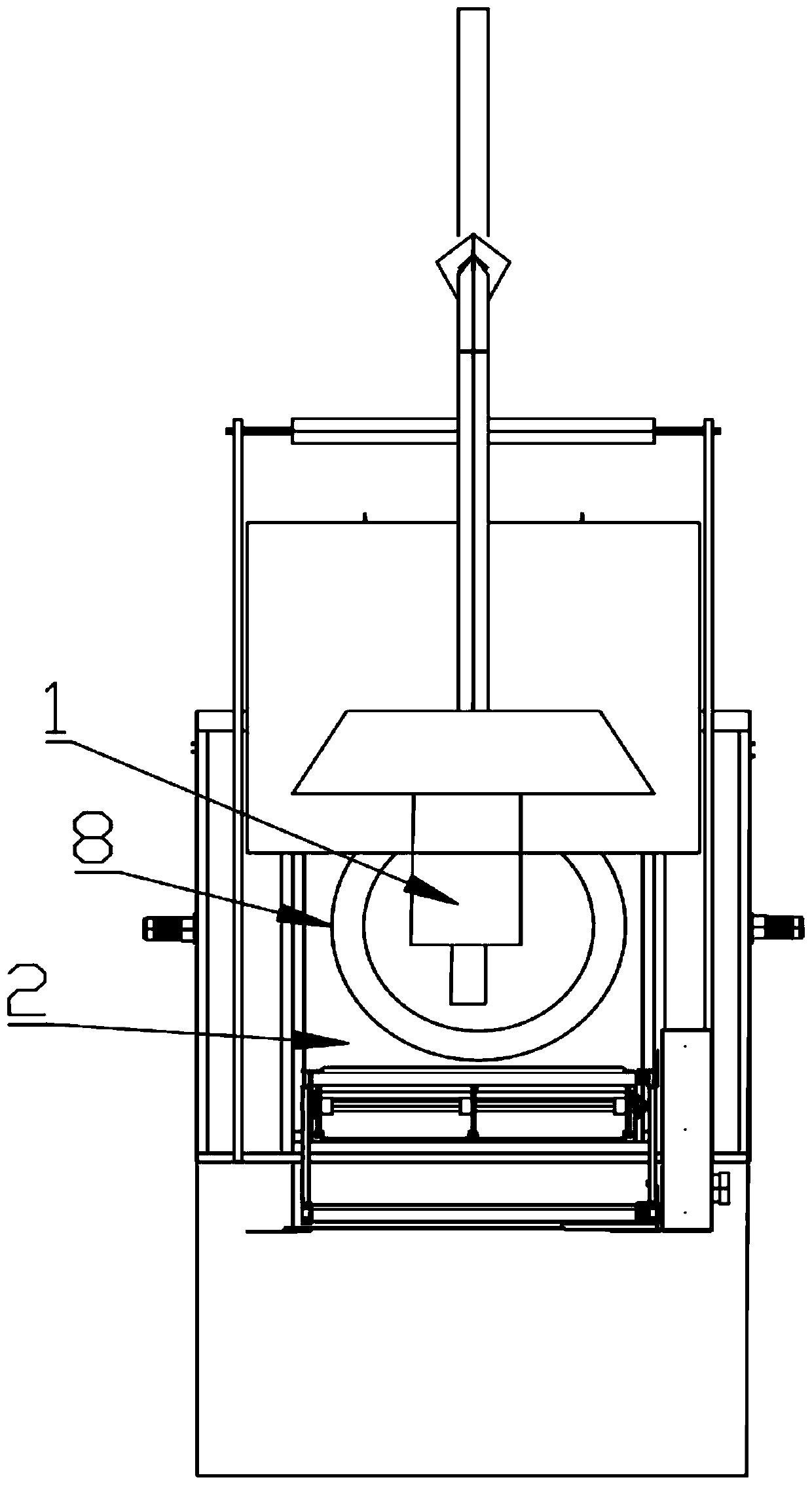

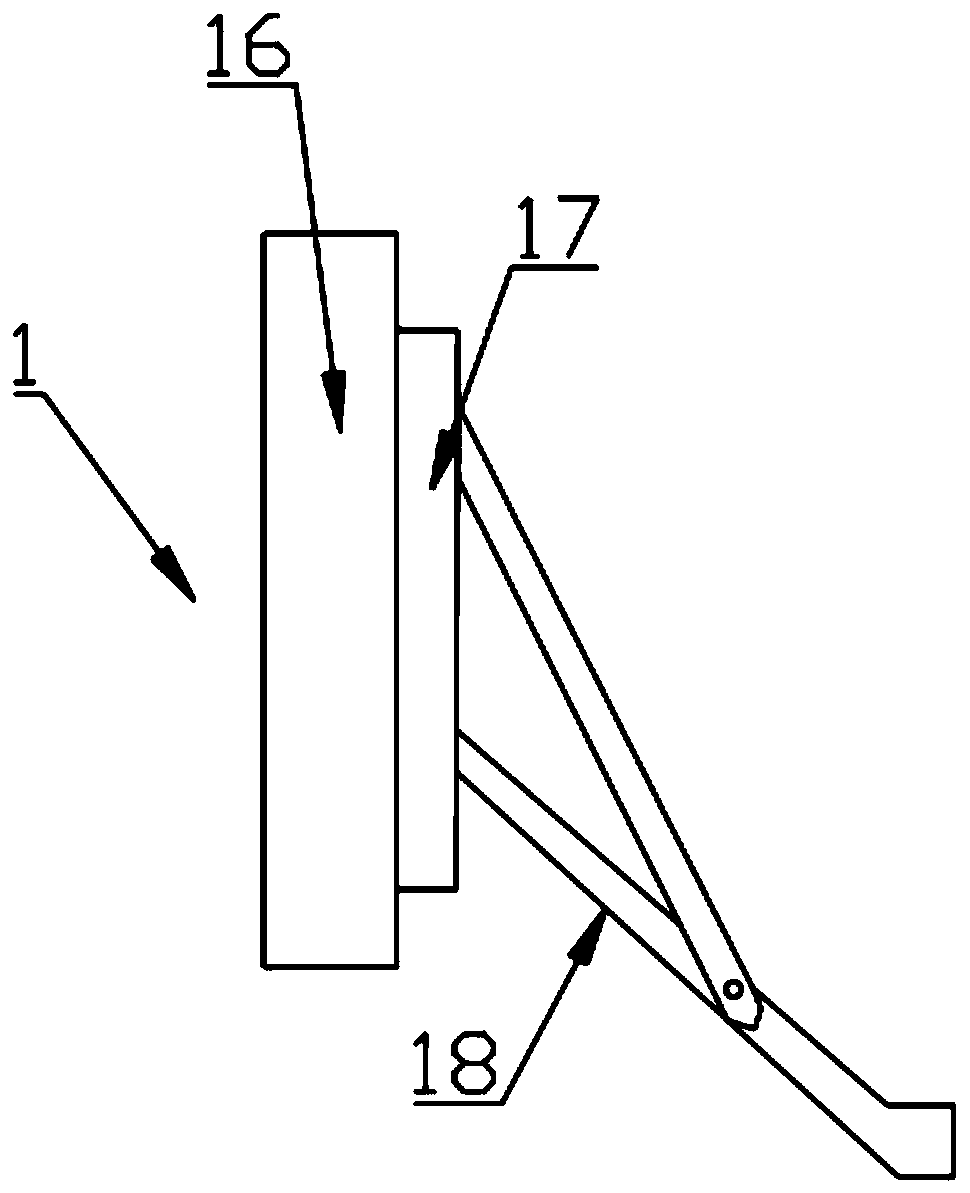

[0031] Embodiment 1: An all-round automatic detection spraying device 8 for aluminum profiles, including a spraying room, a detection device, a spraying device 8, a rotating device and a controller, the detection device, the spraying device 8, the rotating device and the The controllers are respectively arranged in the spraying chamber, and the rotating device includes a mounting box, several supporting bases 16, several clamping heads 1, a rotating disc 17, a first driving mechanism and a first hydraulic driving mechanism, and each of the The support base 16 is arranged on both sides of the installation box, the rotating disc 17 is rotationally connected with the supporting base 16, the bottom of the rotating disc 17 is drivingly connected with the first driving mechanism, and each clamping head 1 is fixedly connected with the rotating disk 17, the first hydraulic drive device is connected with each clamping head 1, and the detection device, the spraying device 8 and the rotat...

Embodiment 2

[0033]Embodiment 2: An all-round automatic detection spraying device 8 for aluminum profiles, including a spraying room, a detection device, a spraying device 8, a rotating device and a controller, the detection device, the spraying device 8, the rotating device and the The controllers are respectively arranged in the spraying chamber, and the rotating device includes a mounting box, several supporting bases 16, several clamping heads 1, a rotating disc 17, a first driving mechanism and a first hydraulic driving mechanism, and each of the The support base 16 is arranged on both sides of the installation box, the rotating disc 17 is rotationally connected with the supporting base 16, the bottom of the rotating disc 17 is drivingly connected with the first driving mechanism, and each clamping head 1 is fixedly connected with the rotating disk 17, the first hydraulic drive device is connected with each clamping head 1, and the detection device, the spraying device 8 and the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com