A sheet metal processing platform device and method for auxiliary cleaning

A technology for processing platforms and sheet metal parts, which is applied in the field of sheet metal processing platform devices, can solve problems such as insufficient cleaning and lack of cleaning and protection devices, and achieve good cleaning effects, resource saving, and comprehensive cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

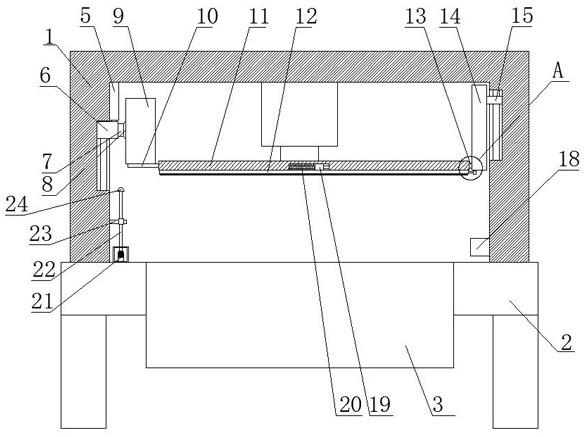

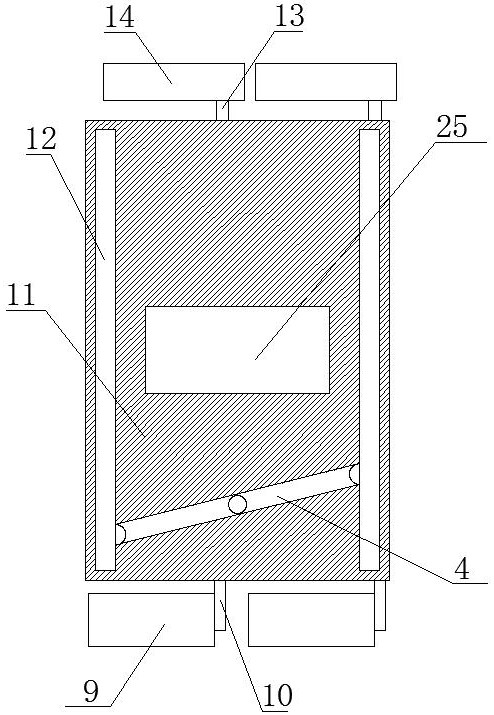

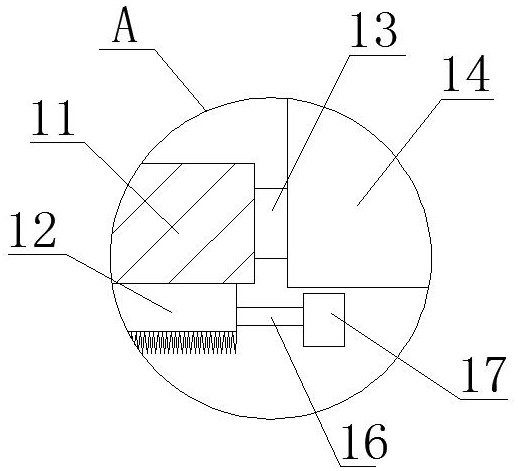

[0036] refer to Figure 1-6 , a sheet metal parts processing platform device for auxiliary cleaning, comprising a box body 1, a base 2 is fixedly installed on the bottom of the box body 1, a recovery box 3 is fixedly installed on the base 2, and a recovery box 3 is fixedly installed on the top inner wall of the box body 1 There is an electric push rod 5, two conveyor belts 9 are slidably installed on the inner wall of one side of the box body 1, the output shaft of the electric push rod 5 is adapted to one of the two conveyor belts 9, and the two conveyor belts 9 are fixedly installed There is the same mounting plate 11, and the bottom of the mounting plate 11 is symmetrically slid to install a cleaning plate 12. The two cleaning plates 12 are matched, and the mounting plate 11 is movably installed on the inner wall of one side of the box body 1. A drive motor 21 is fixedly installed on the top, and the drive motor 21 is compatible with one of the two conveyor belts 9. A baffl...

Embodiment 2

[0053] refer to Figure 1-6 , a sheet metal processing platform device for auxiliary cleaning, including a box body 1, the bottom of the box body 1 is fixed with a base 2 by welding, the setting of the base 2 makes the whole device more stable, and the base 2 is fixed by welding A recovery box 3 is installed, and the setting of the recovery box 3 makes the collection of debris more convenient. An electric push rod 5 is fixedly installed on the top inner wall of the box body 1 by welding, and two Conveyor belt 9, the output shaft of the electric push rod 5 is adapted to one of the two conveyor belts 9, the same mounting plate 11 is fixedly installed on the two conveyor belts 9 by welding, and the bottom of the mounting plate 11 is symmetrically slidingly installed with cleaning Plate 12, the two cleaning plates 12 are compatible, the mounting plate 11 is movably installed on the inner wall of one side of the box body 1, and the bottom inner wall of the box body 1 is fixedly ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com