Automatic jacking cylinder frame formwork system for concrete structure construction and method thereof

A concrete structure and formwork technology, applied in the field of automatic jacking cylinder formwork system in concrete structure construction, can solve the problems of many safety hazards and low climbing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

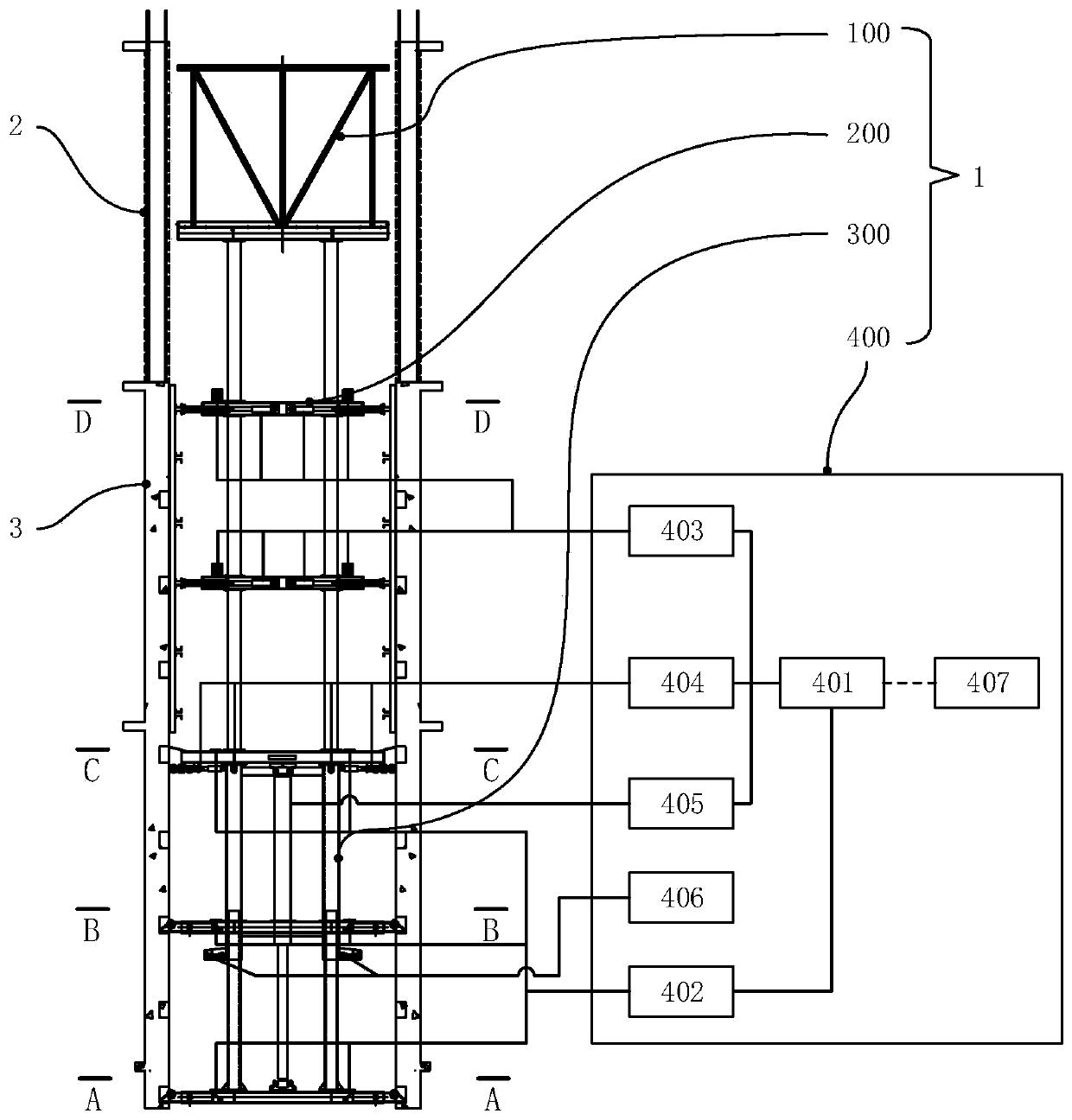

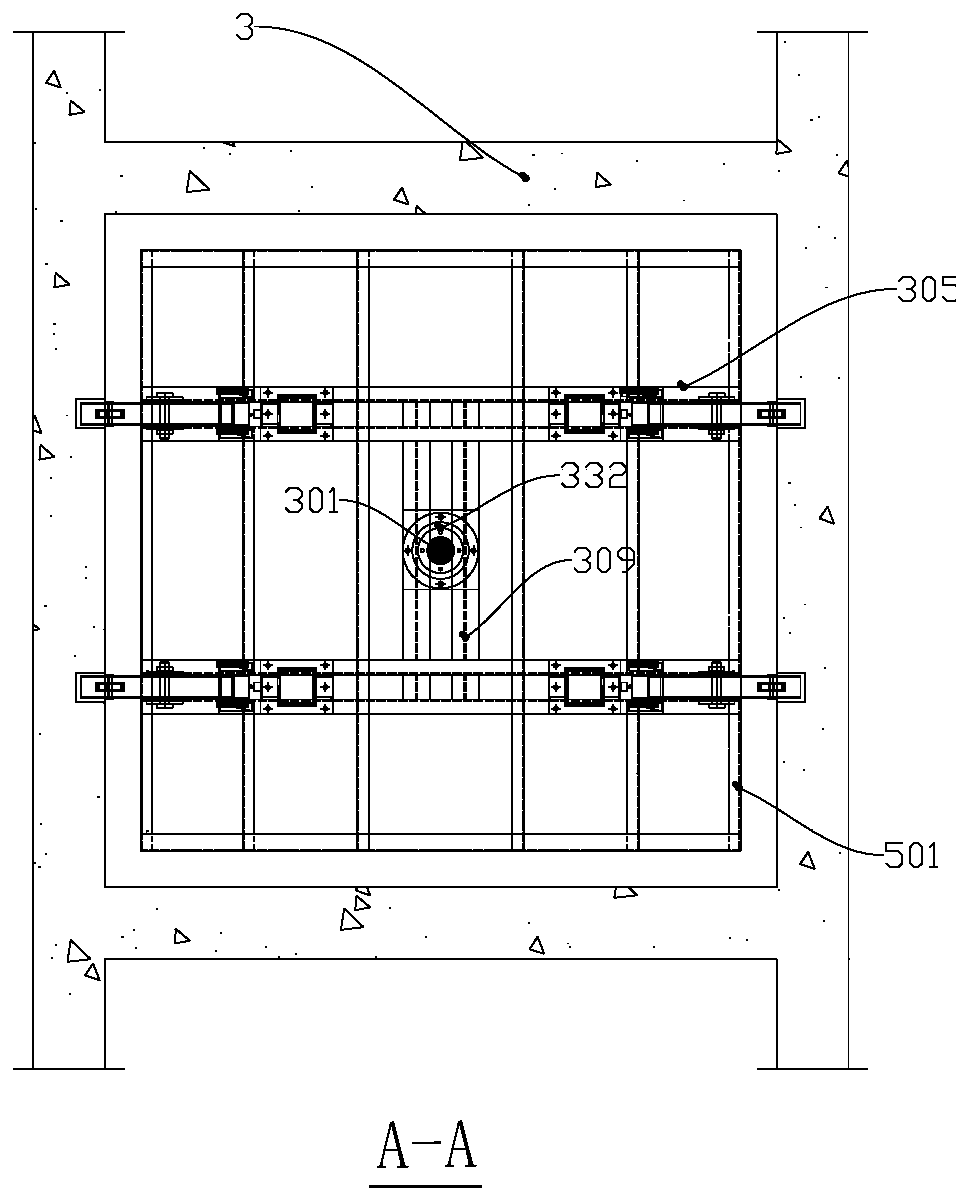

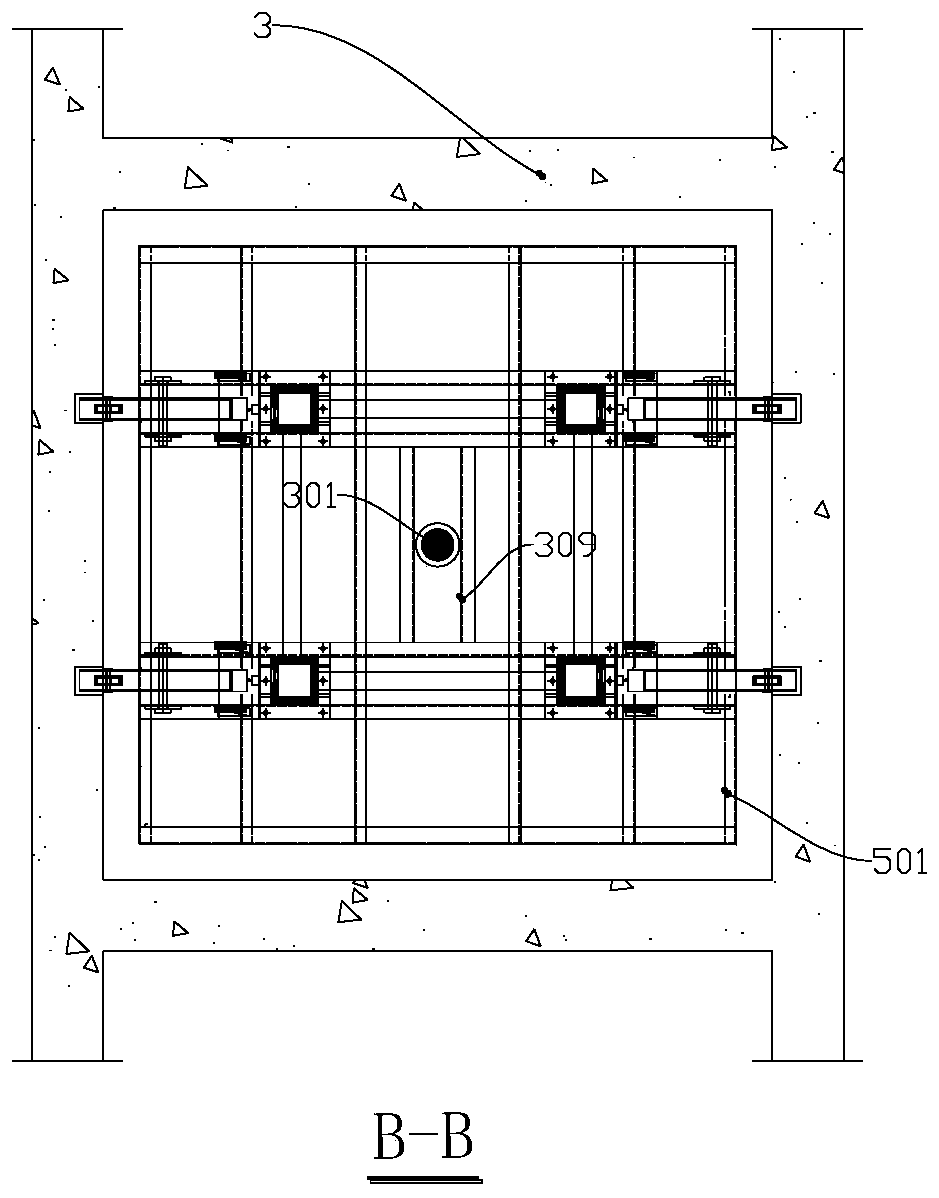

[0067] Combine below Figure 1 to Figure 16 A concrete structure construction automatic jacking cylinder formwork system and method of the present invention will be described in detail.

[0068] Please refer to Figure 1 to Figure 16 , an automatic jacking cylinder formwork system for concrete structure construction, including a formwork operating system 200, a steel bar operating frame 100, a frame jacking system 300, and an automatic control system 400. The formwork operating system 200 includes a column 201 and a formwork opening and closing device 202 And stereotyped formwork 203, the upper and lower ends of column 201 are all provided with connecting plate 103; Formwork opening and closing device 202 comprises box girder 221, box girder pin shaft 222, rib plate 223, limiting plate 224, formwork oil cylinder 225, formwork push-pull rod 226. Formwork connector 227, the limit plate 224 is embedded inside the box girder 221, and its surroundings are firmly connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com