Patents

Literature

36results about How to "Reduce construction cost input" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

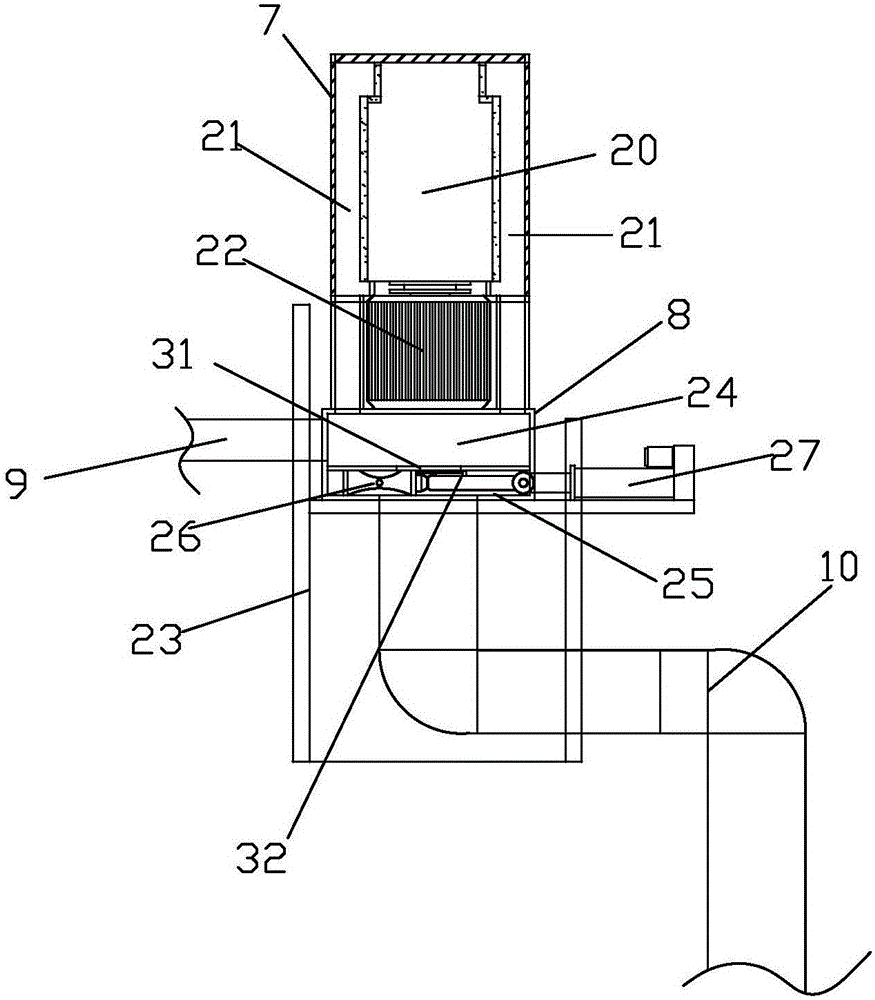

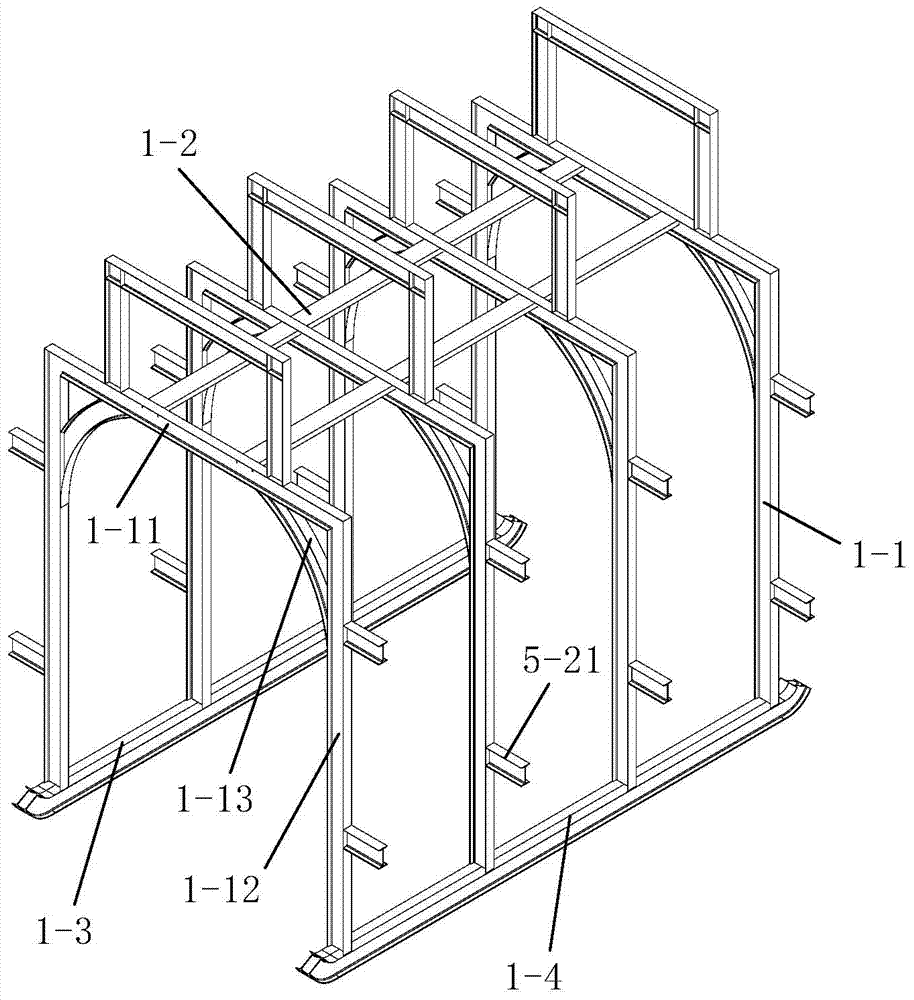

Combined type telescopic sleeve jacking device and method

ActiveCN111058618AImprove structural construction efficiencyImprove construction efficiencyForms/shuttering/falseworksBraced frameArchitectural engineering

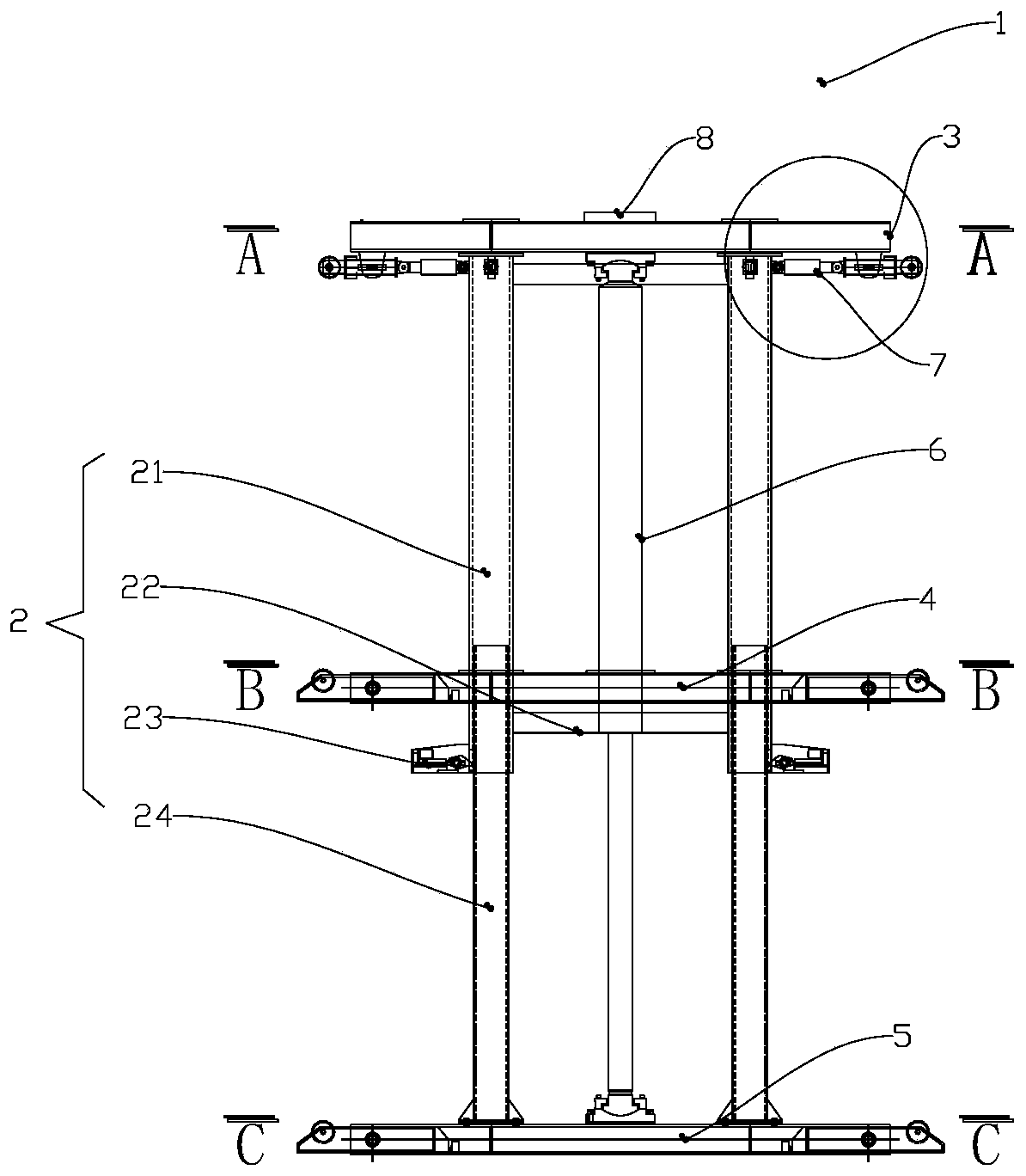

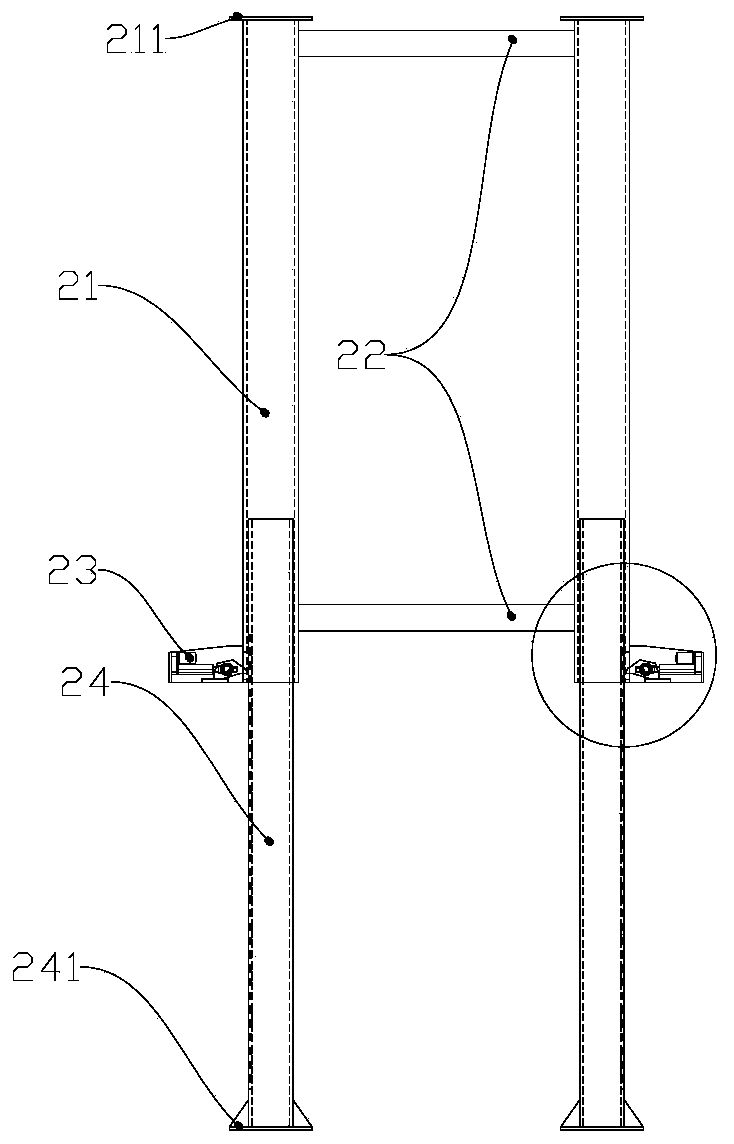

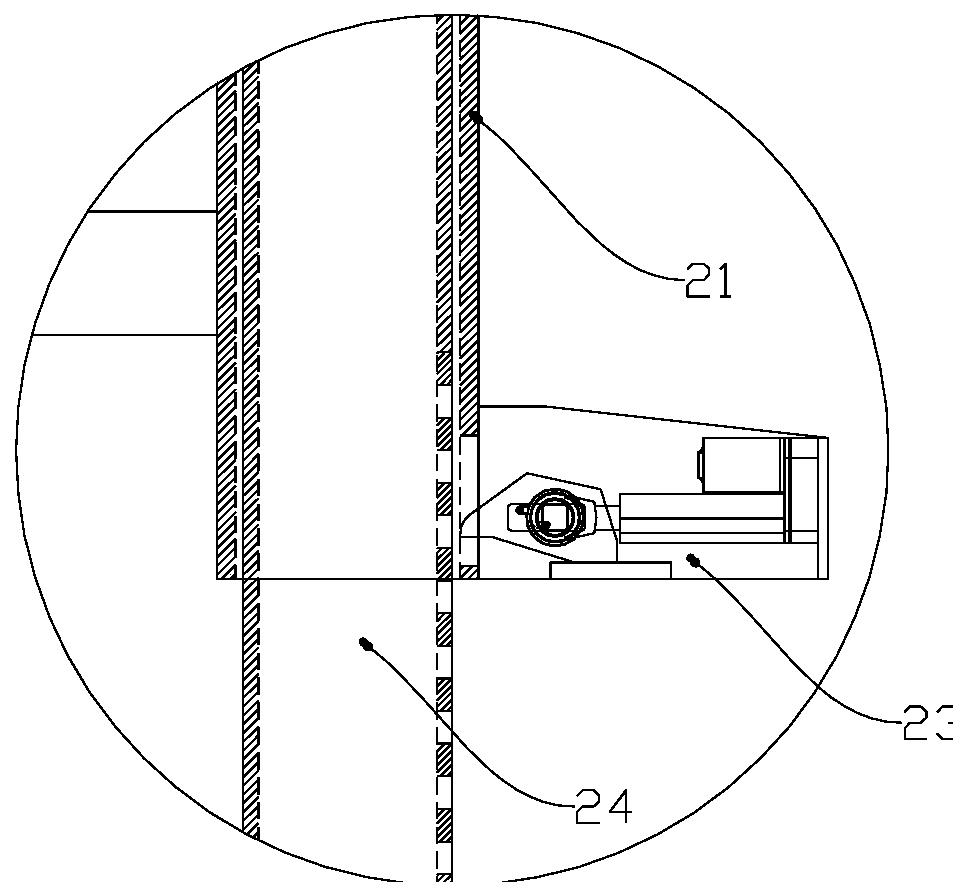

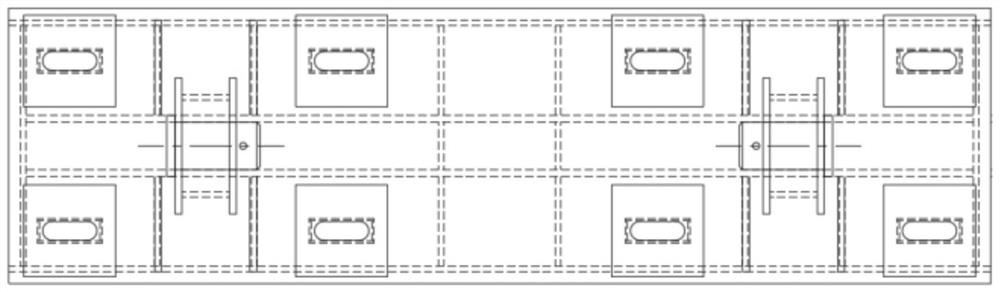

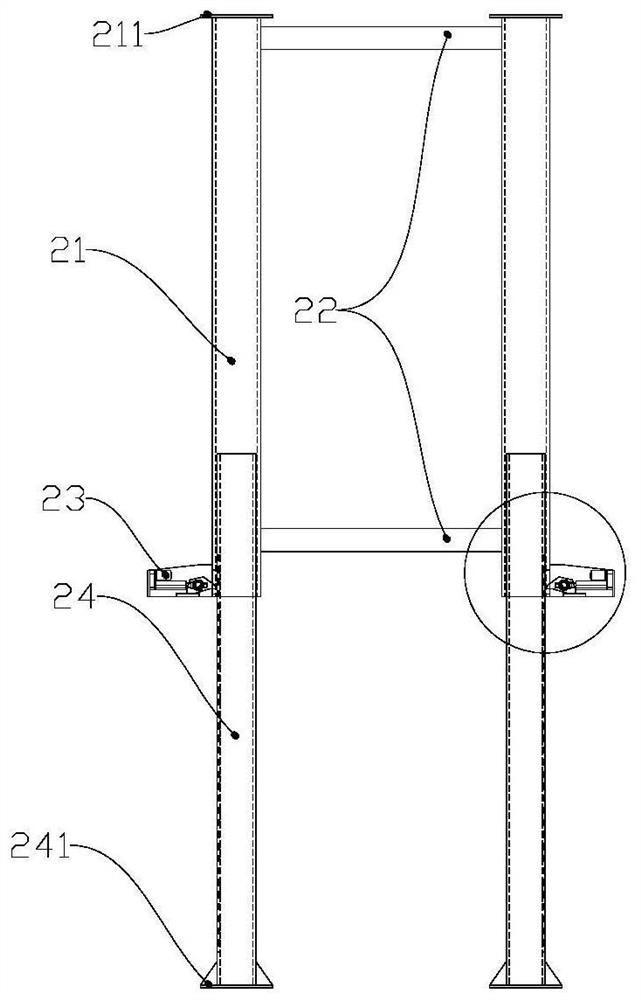

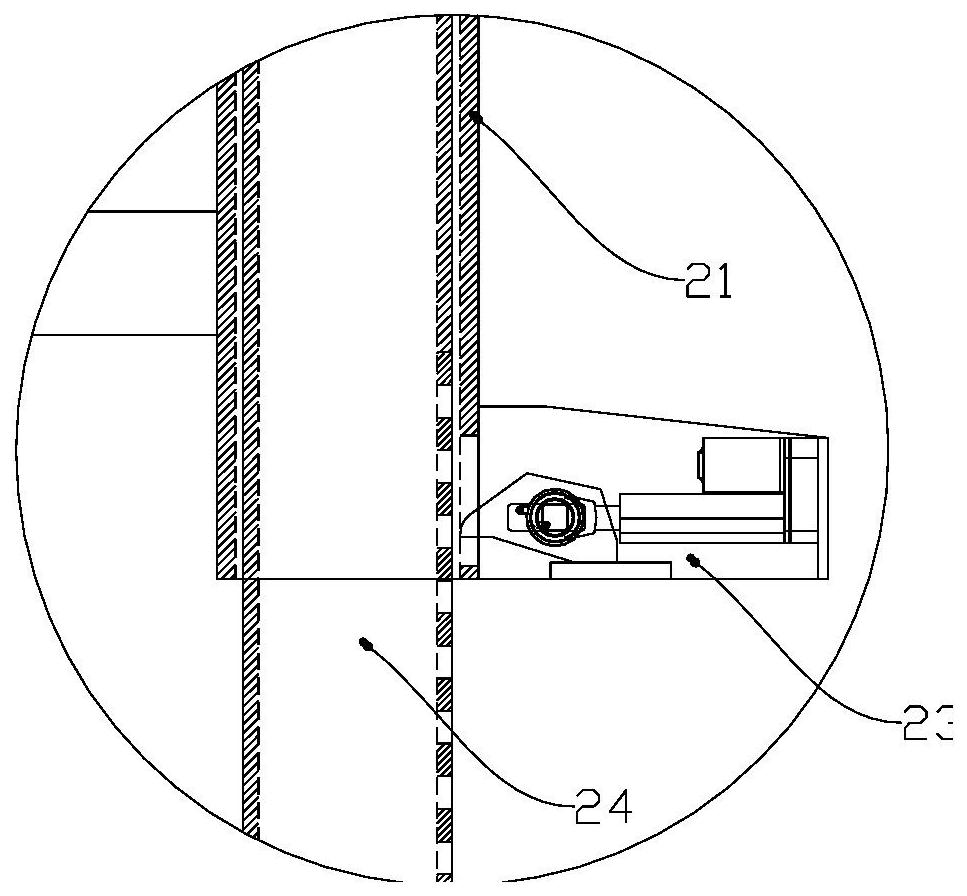

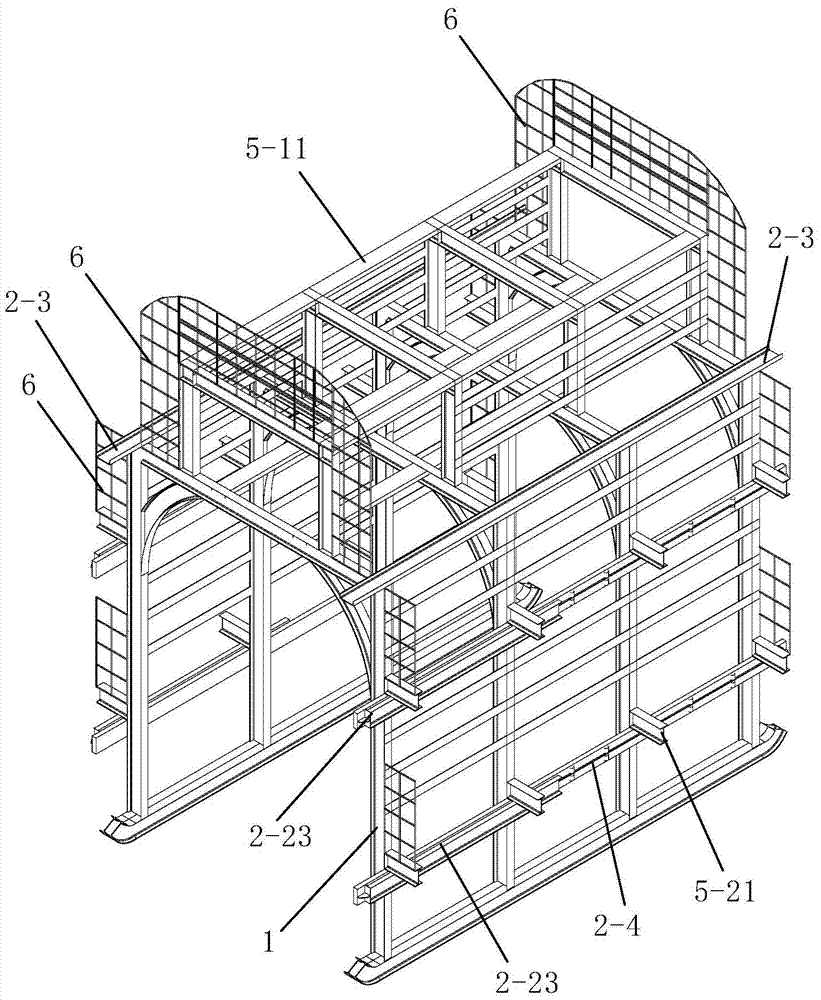

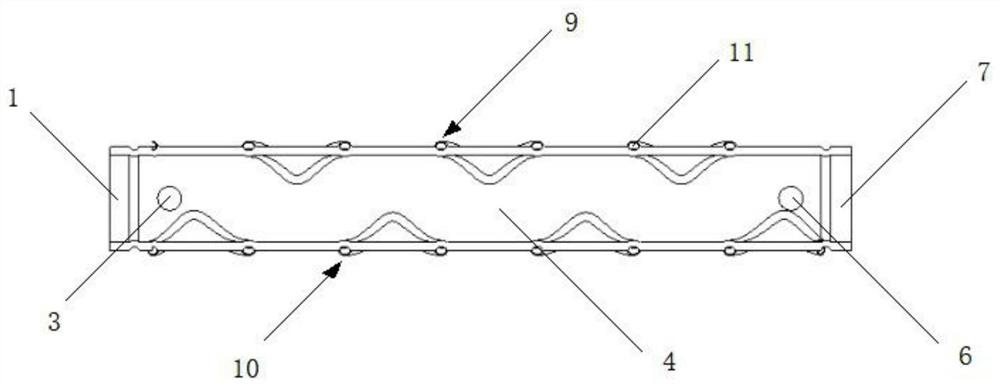

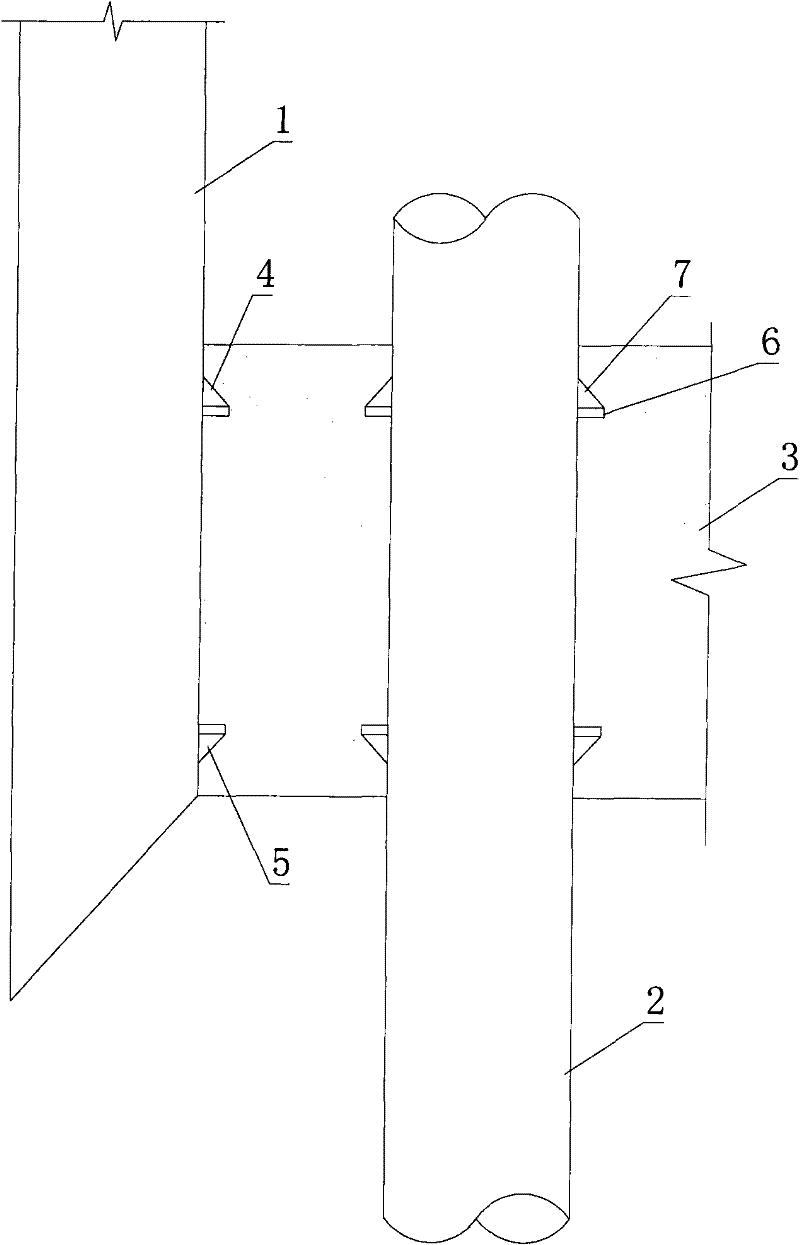

The invention belongs to the technical field of construction engineering construction, and particularly relates to a combined type telescopic sleeve jacking device and method. The device solves a series of problems that in high-rise and super high-rise building concrete cylinder construction, a traditional climbing formwork system is complex in a power system, large in transmission mechanism number, poor in narrow cylinder space adaptability, low in combined construction flexibility and the like. The combined type telescopic sleeve jacking device comprises a plurality of jacking unit modules,a horizontal jacking frame, an upper supporting frame, a lower supporting side frame and a plurality of longitudinal connecting beams, wherein each unit jacking module comprises a jacking oil cylinderand a telescopic sleeve frame; the jacking oil cylinders are arranged at the center positions of the telescopic sleeve frames, and the upper ends of the jacking oil cylinders are connected with the horizontal jacking frame; and the jacking oil cylinders penetrate through gaps between the longitudinal connecting beams of the upper supporting frame, and the lower ends of the jacking oil cylinders are connected with the lower supporting frame. By providing a single-oil-cylinder jacking module device with a telescopic sleeve frame, formwork system jacking operation can be independently carried out, multi-module combined jacking can be carried out according to large-space cylinder construction needs, and large-load three-dimensional operation is achieved.

Owner:SHANGHAI CONSTRUCTION GROUP

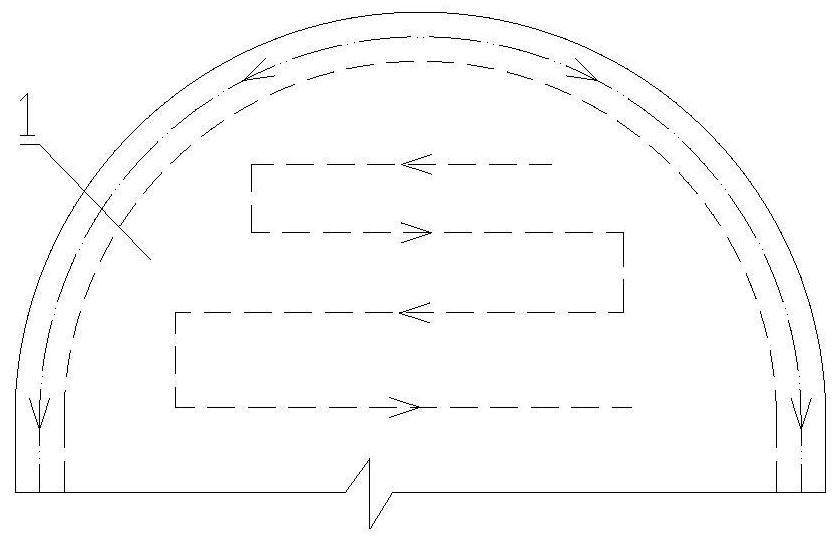

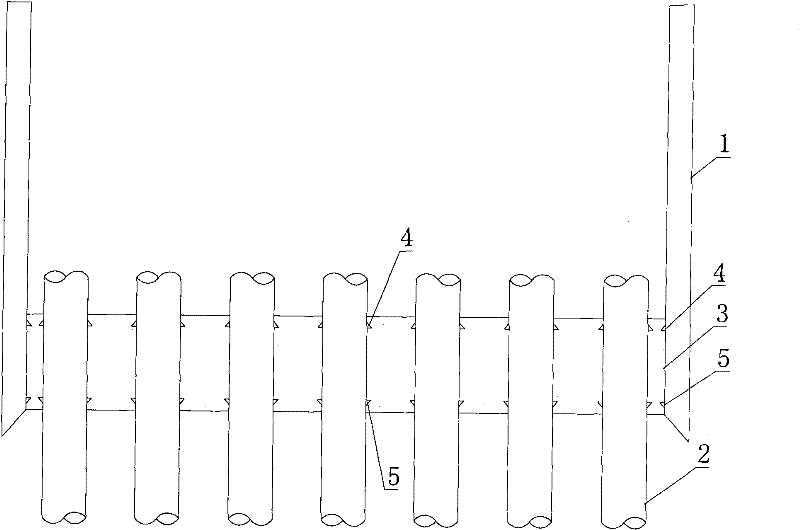

Airbag type inner framework form traveler and primary tunnel supporting shotcrete construction method

ActiveCN105507927ASimple structureEasy to processMining devicesUnderground chambersShotcreteArchitectural engineering

The invention discloses an airbag type inner framework from traveler and a primary tunnel supporting shotcrete construction method. The form traveler comprises a movable supporting framed bent, an inflatable formwork located on the outer side of the movable supporting framed bent, and a retractable supporting device for supporting the inflatable formwork, and the retractable supporting device is installed on the movable supporting framed bent and located on the inner side of the inflatable formwork. The construction method includes the steps: firstly, forwarding the airbag type inner framework from traveler in place; secondly, performing primary tunnel supporting shotcrete construction; thirdly, performing primary tunnel supporting shotcrete construction on a next tunnel section; fourthly, repeating the third step for multiple times till the primary tunnel supporting shotcrete construction process of all the tunnel sections is finished. The airbag type inner framework from traveler is reasonable in design, simple to construct and good in using effect, resilience rate of primary tunnel supporting shotcrete is effectively controlled through an airbag type inner framework, construction efficiency is high, construction period is short, construction quality is high, and zero resilience rate of primary tunnel supporting shotcrete can be realized.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

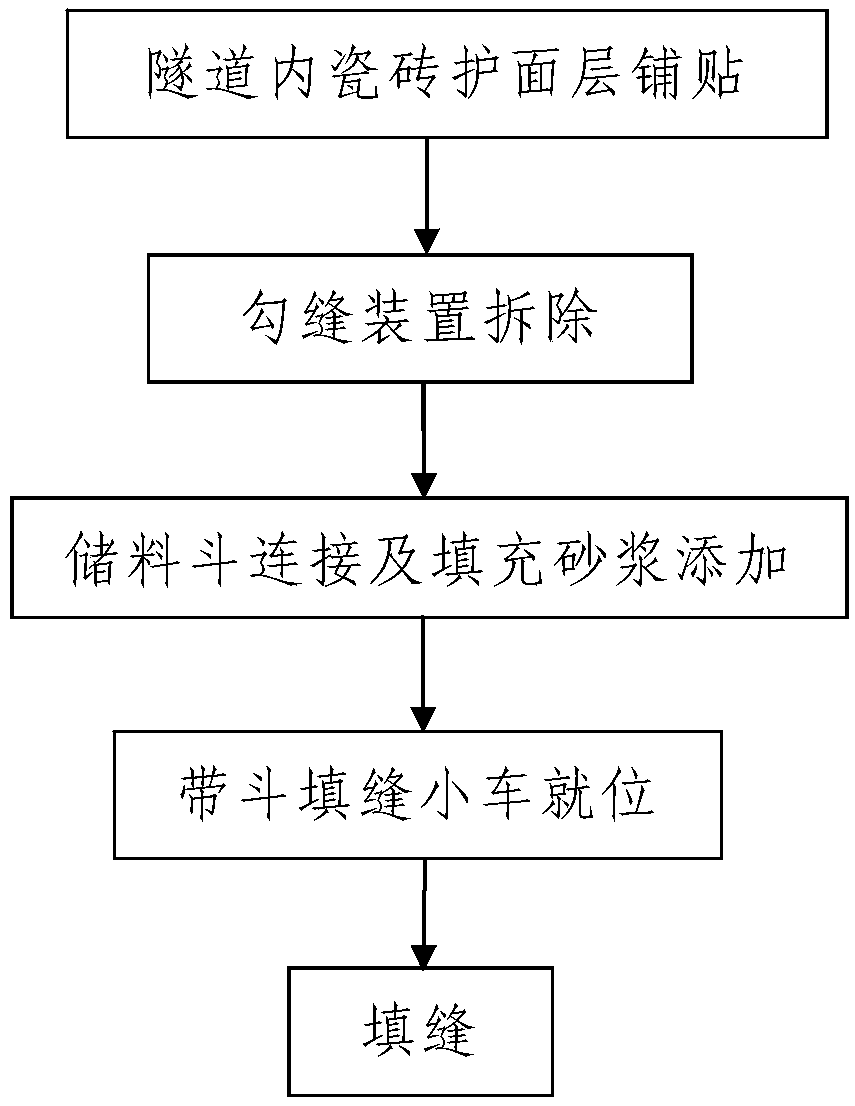

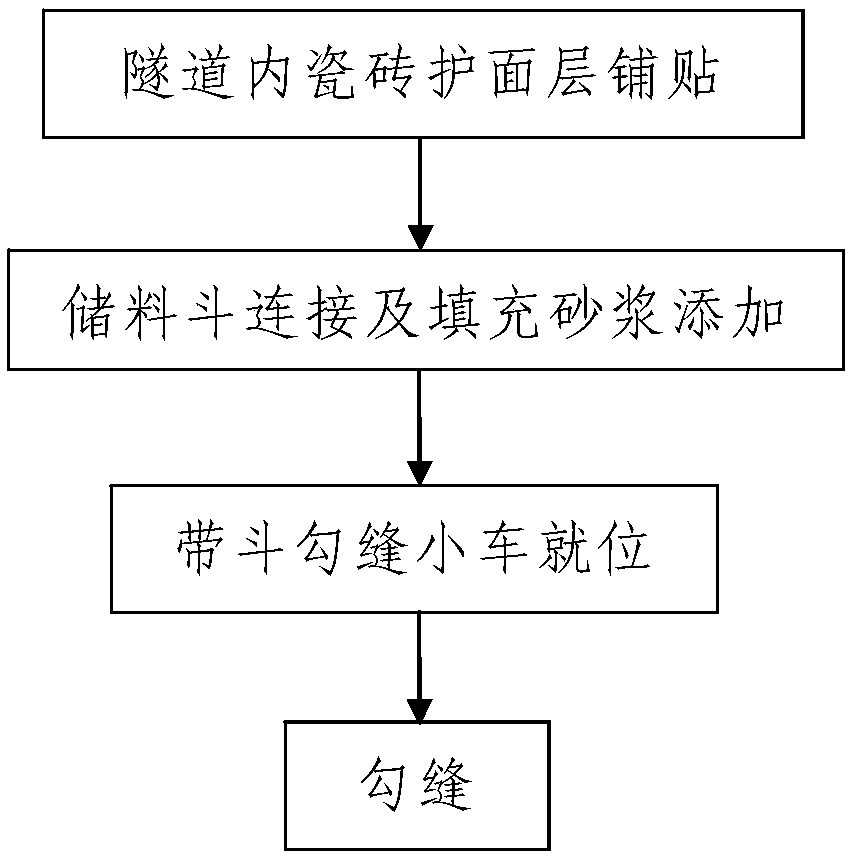

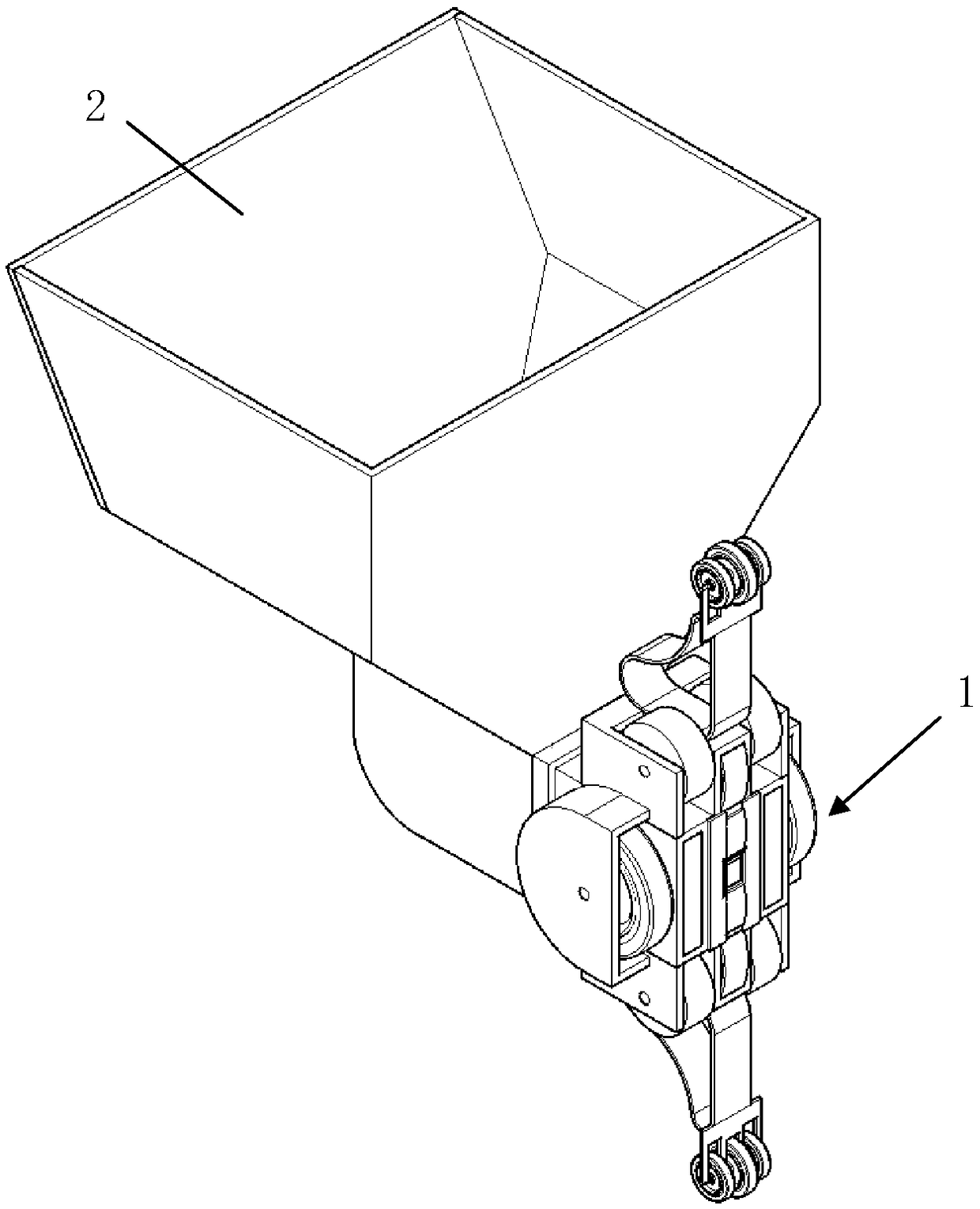

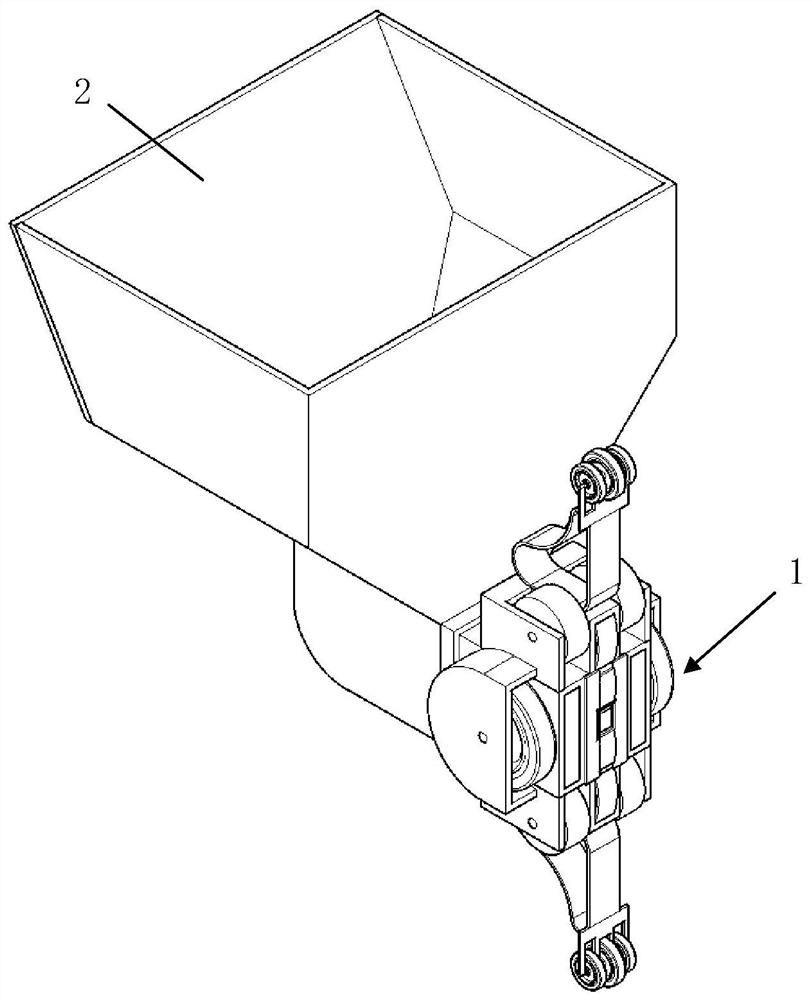

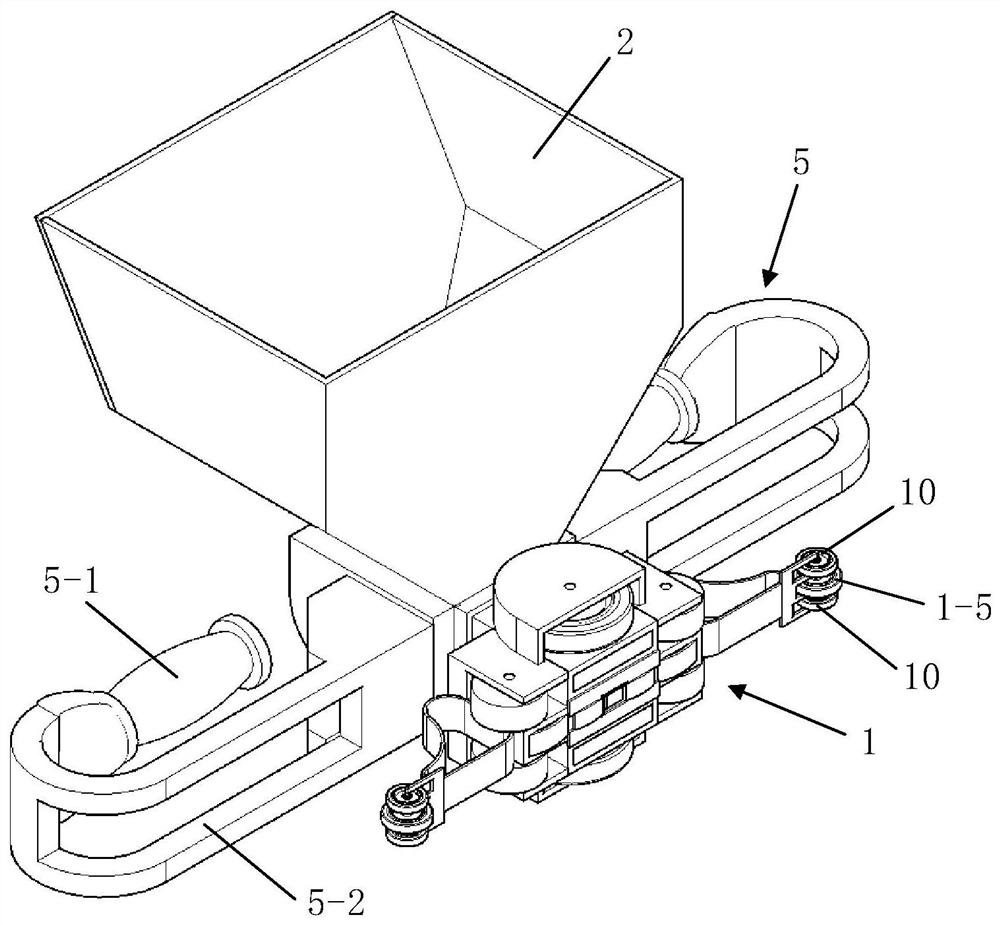

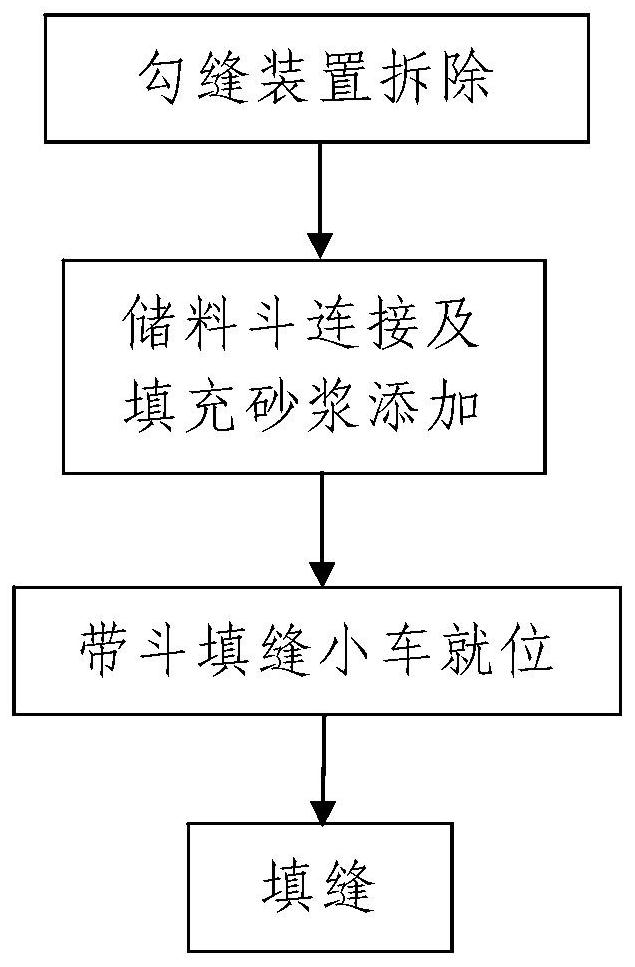

Caulking and jointing construction method for brick joints of tiles in tunnel

ActiveCN109296184AThe method steps are simpleReasonable designBuilding constructionsBrickMechanical engineering

The invention discloses a caulking and jointing construction method for brick joints of tiles in a tunnel. The caulking and jointing construction method is characterized in that a brick joint caulkingand jointing device is adopted to caulk or joint the brick joints of the tiles in the tunnel; the brick joint caulking and jointing device includes a caulking and jointing trolley capable of moving back and forth on the surface of a masonry structure and a storage hopper for storing filling mortar which is used for filling the brick joints; when caulking is actually performed, the steps of jointing device removal, storage hopper connection, filling mortar adding, being-in-place of a caulking trolley with a hopper and caulking are included; and when jointing is actually performed, the steps ofstorage hopper connection, filling mortar adding, being-in-place of a jointing trolley with a hopper and jointing are included. The caulking and jointing construction method has reasonable design, simple and convenient construction, high construction efficiency and good use effect, the movable brick joint caulking and jointing device is used for caulking or jointing the brick joints, the fillingmortar can be automatically fed into the treated brick joints, compaction and groove pressing forming can be performed on the filling mortar fed into the brick joints, and the quality of caulking andjointing can be ensured.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Method for reducing thickness of subsealing concrete of steel cofferdam and preventing seepage

ActiveCN102094428APlay the role of water stopImprove carrying capacityFoundation engineeringTransfer modeCofferdam

The invention discloses a method for reducing the thickness of subsealing concrete of a steel cofferdam and preventing seepage, comprising the following steps of: a. assembling the steel cofferdam and welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure along the inner wall of the steel cofferdam; b. feeding the steel cofferdam in water; c. welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure on the outer wall of each steel protecting tube and sequentially punching the steel protecting tubes into a foundation in the steel cofferdam; d. constructing all drilling piles; e. cleaning the foundation in the steel cofferdam and flushing the steel cofferdam and the shearing resistant structures underwater on the steel protecting tubes; f. pouring the subsealing concrete to be combined with the steel protecting tubes, the steel cofferdam and the shearing resistant structure into a whole; and g. pumping water from the steel cofferdam and constructing a bearing platform. According to the method, by arranging the shearing resistant structures, after water in the steel cofferdam is pumped, the force transfer mode of the subsealing concrete and the inner wall of the steel cofferdam and the outer walls of the steel protecting tubes is converted into a bonding force and a shearing force from the mutual bonding force, so that the dereference of the concrete bearing capacity accords with the reliable basis and the thickness of the subsealing concrete can be reduced; and the water seepagae in the steel cofferdam can be prevented.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

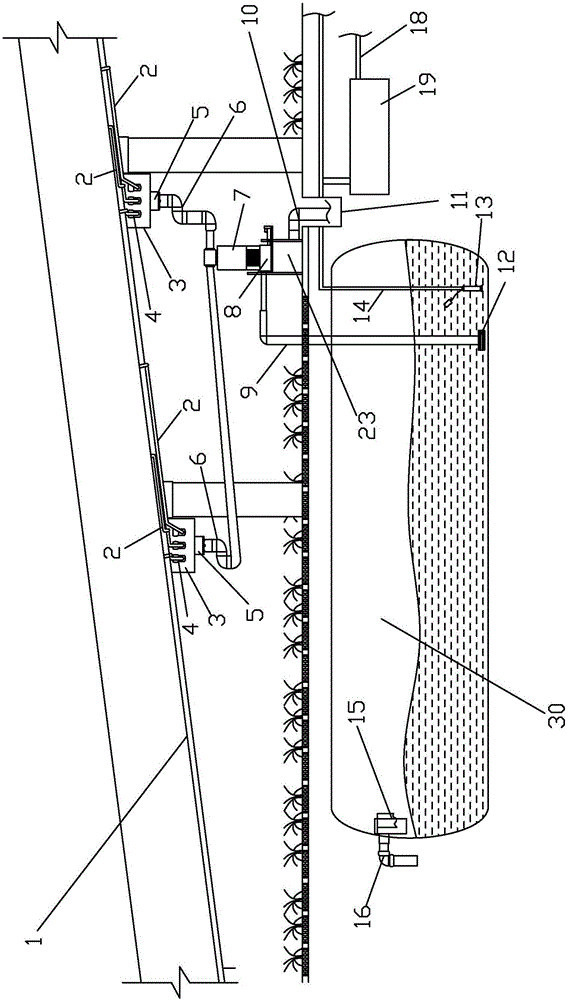

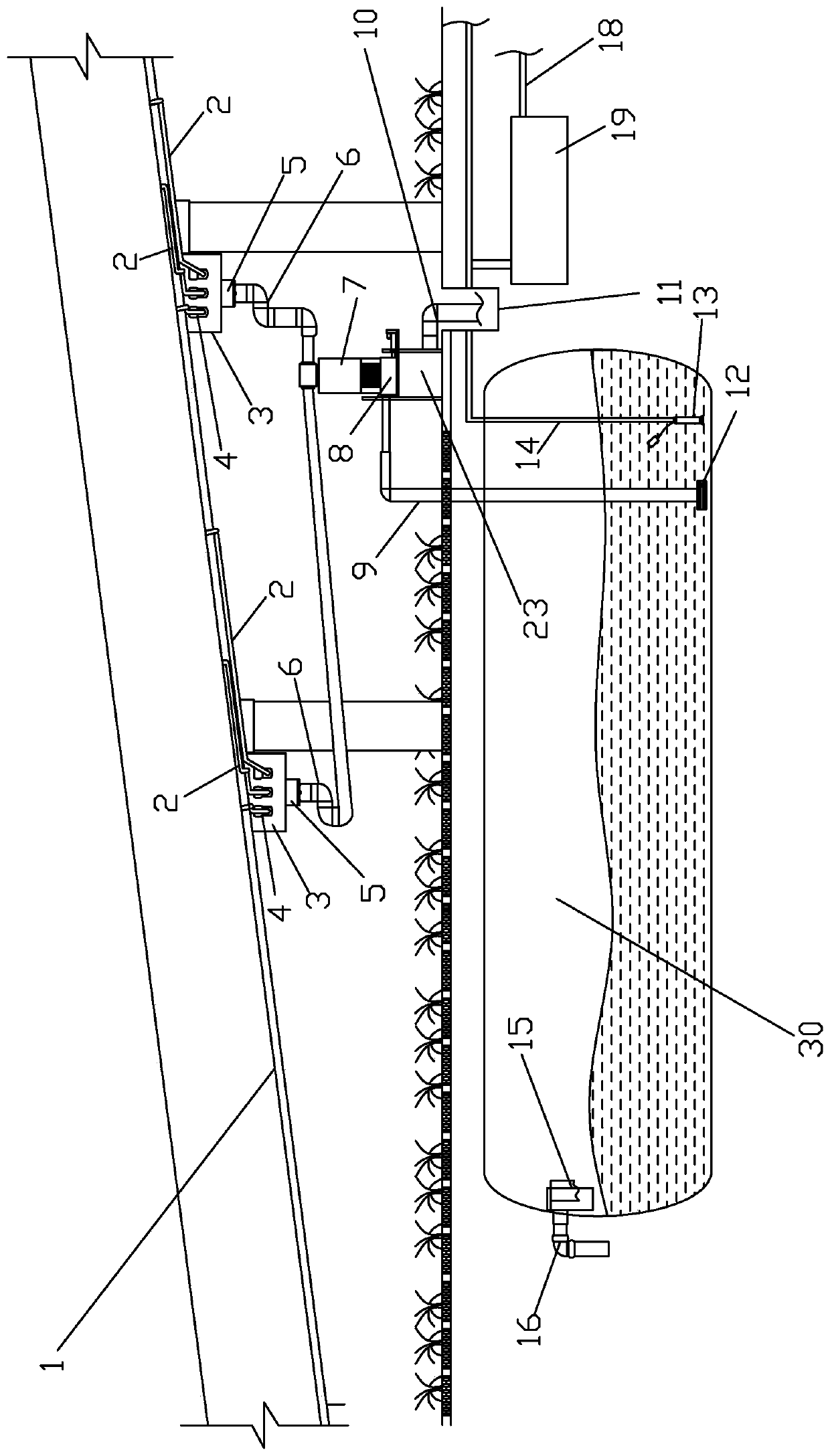

Rainwater recycling system for sponge city overpass and construction method of rainwater recycling system

ActiveCN106758799AAlleviate drainage problemsBarrier entryFatty/oily/floating substances removal devicesSewerage structuresWater storageEngineering

The invention discloses a rainwater recycling system for sponge city overpass and a construction method of the rainwater recycling system. The rainwater recycling system comprises a rainwater collection device, rainwater pretreatment equipment and a water storage well, the rainwater collection device comprises a rainwater pipe and a collector, a water collection pump is mounted on the collector, and the rear end of the rainwater pipe is connected onto the water collection pump while the front end of the same is connected onto a deck of the overpass; the lower end of the collector is connected with a first guide pipe, the other end of the first guide pipe is connected with the rainwater pretreatment equipment, a diverter is mounted at the lower end of the rainwater pretreatment equipment, a second guide pipe is connected on the diverter and connected to the water storage well, a submerged pump is mounted in the water storage well, and a recycling pipe is connected on the submerged pump. An existing overpass draining pipeline is introduced into the collector, and rainwater is purified with the help of the rainwater pretreatment equipment, guided into the water storage well and then recycled through the recycling pipe, so that reasonable utilization of rainwater resources is realized, city water consumption pressure is relieved, the draining problem of the overpass is solved effectively, and city traffic is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

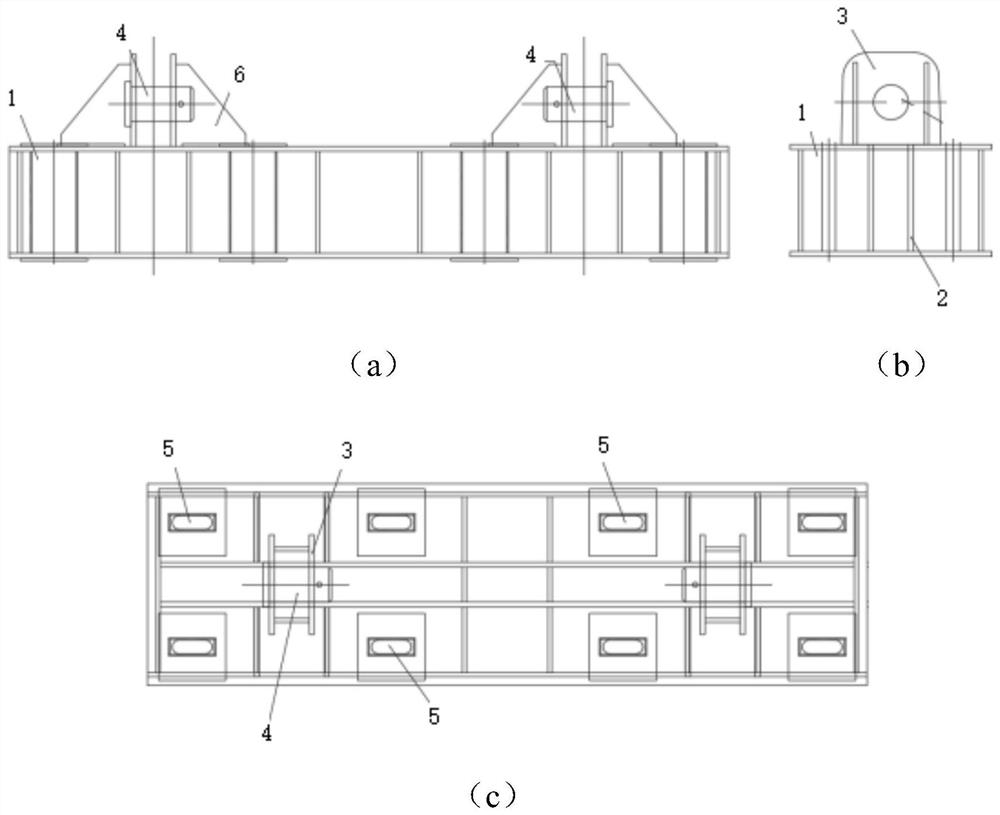

Method for processing, manufacturing and constructing prefabricated small box girder hanging bracket

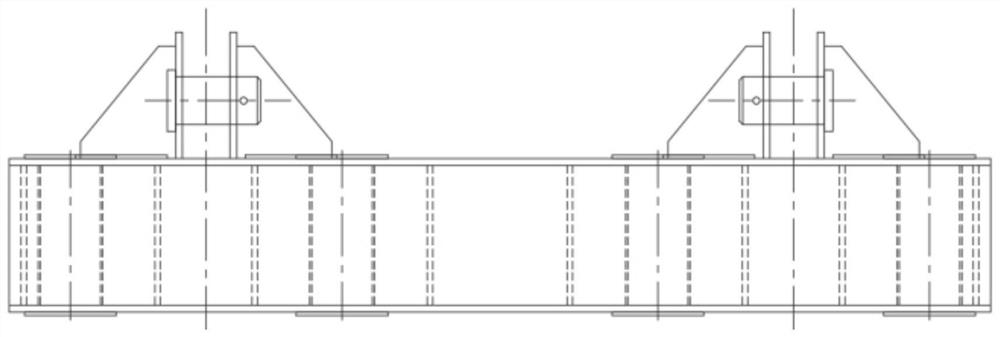

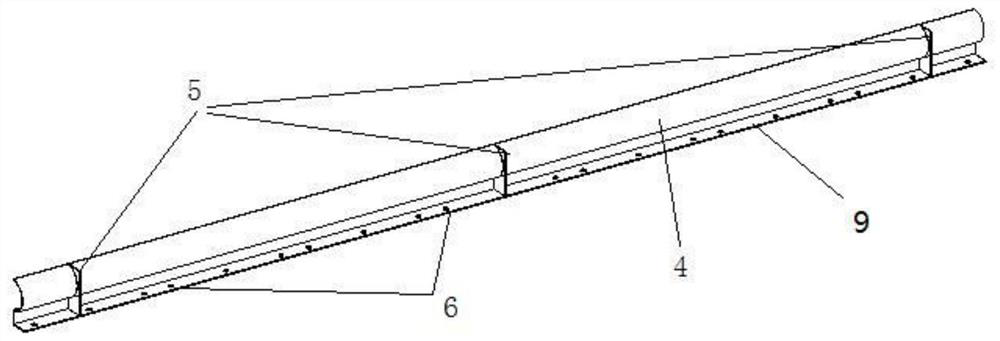

PendingCN113699891ASmooth liftRealize vertical tilt hoistingBridge erection/assemblyLoad-engaging elementsConstruction engineeringBox girder

The invention relates to a method for processing, manufacturing and constructing a prefabricated small box girder hanging bracket, which comprises a small box girder hanging bracket structure design and processing and manufacturing method: the small box girder hanging bracket structure is formed by forming a group by two hanging brackets, each hanging bracket is provided with eight waist-shaped hoisting holes, and eight preformed holes are reserved in corresponding positions of a small box girder; the hanging bracket is connected with the small box girder through a high-strength hanging rod / finish rolling deformed steel bar; two lifting lugs are arranged on each lifting frame and are connected through lifting pin rods, and lifting operation can be carried out through shackles and lifting equipment; a small box girder mounting and small box girder hanging bracket using method comprises the steps that small box girders are transferred and loaded in a prefabricated part factory through the small box girder hanging bracket; the small box girder is hoisted and installed on the top of the bent cap through the small box girder hoisting frame after being transported to an installation site, and the small box girder hoisting frame is dismantled after the small box girder is hoisted. The problems that the small box girder is difficult to install in a complex environment and the small box girder structure is uneven in stress under a special hoisting working condition are solved; and by using the small box girder hanging bracket, the construction safety is greatly improved, and the construction cost is saved.

Owner:SHANGHAI FOUND ENG GRP

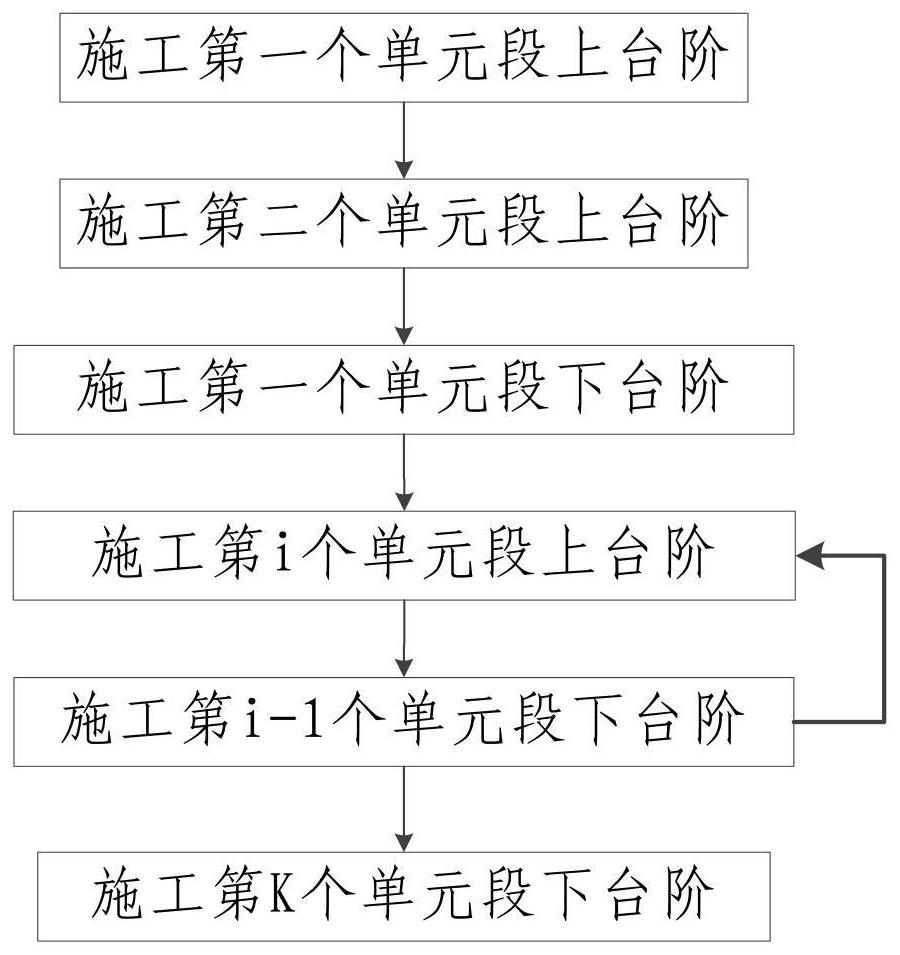

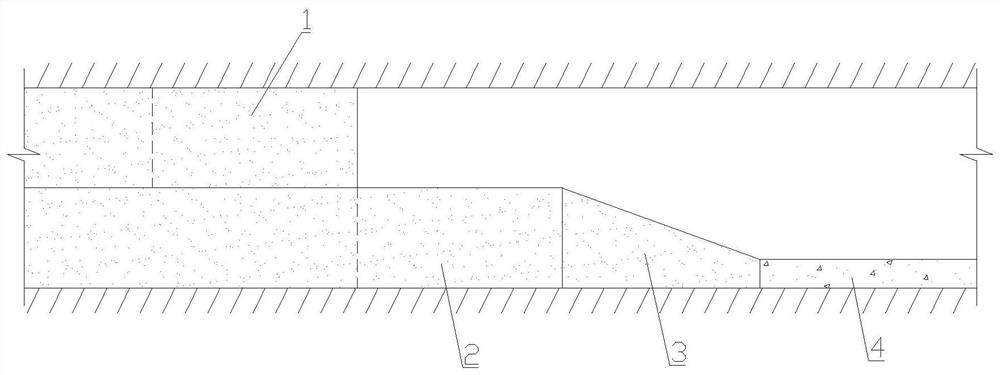

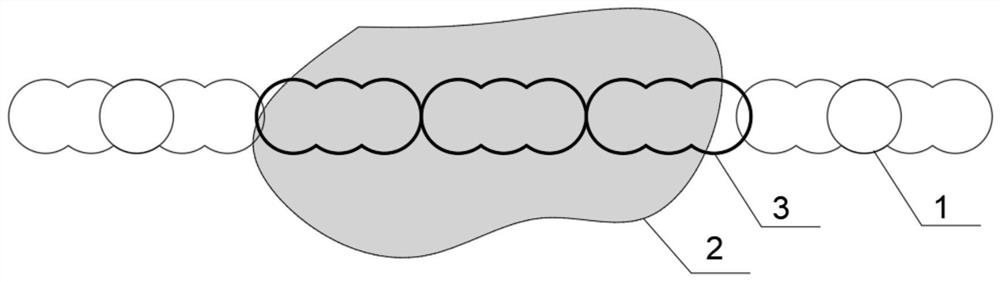

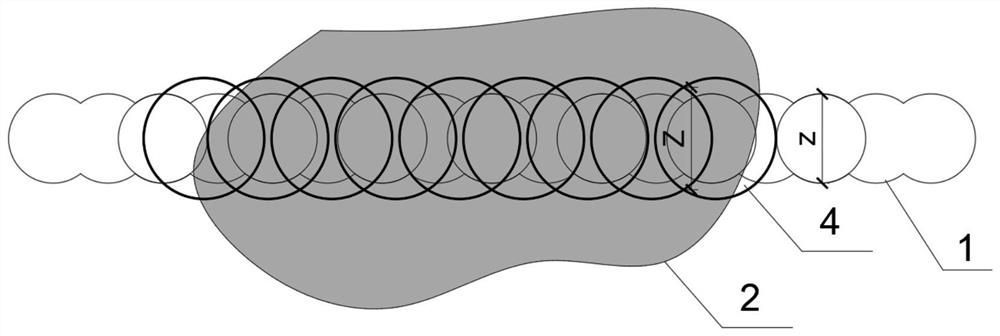

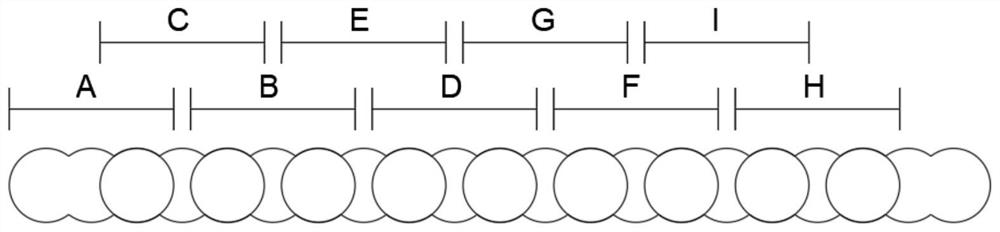

Cantilever excavator-based construction method for single-line tunnel close to operation line

InactiveCN112459801AEnsure safetyImprove working environmentUnderground chambersTunnel liningShotcreteArchitectural engineering

The invention discloses a cantilever excavator-based construction method for a single-line tunnel close to an operation line. The construction method comprises the following steps that firstly, an upper step of a first unit section is constructed; secondly, an upper step of a second unit section is constructed; thirdly, a lower step of the first unit section is constructed; fourthly, an upper stepof an i unit section is constructed; fifthly, a lower step of an i-1 unit section is constructed; sixthly, the fourth step to the fifth step are repeated till excavation of an upper step of aK unit section and excavation of a lower step of a K-1 unit section are completed; and seventhly, a lower step of the K unit section is constructed. A cantilever tunneling machine is applied to construction of the single-line tunnel close to the operation line, the tunnel is excavated through a non-blasting method, the influence of blasting vibration on the operation line is avoided,multi-cycle excavation supporting construction can be conducted every day, the safety of the operation line can be effectively guaranteed, tunnel overexcavation is effectively controlled, the use amount of primary supporting sprayed concrete is reduced, the construction cost investment is reduced, and the concrete ultra-consumption construction problem which is difficult to solve by a traditionaldrilling and blasting method is solved.

Owner:中铁二十局集团市政工程有限公司

Double-wall steel hanging box cofferdam steel protection barrel inserting and beating accurate positioning method

InactiveCN110939147AMeet the positioning tolerance requirementsIncrease flexibilityBulkheads/pilesKeelCofferdam

The invention provides a double-wall steel hanging box cofferdam steel protection barrel inserting and beating accurate positioning method. After lofting, cofferdam splicing is conducted; a keel is installed, and guide rings are arranged; then, cofferdam water immersing is conducted, and an inserting and beating hole position of the cofferdam is adjusted to the designed pile position; a steel protection barrel is lowered for steel protection barrel inserting and beating; and after a first positioning pile is inserted and beaten, an ejector rod is adjusted to finely adjust the plane position ofthe cofferdam, the plane position of the cofferdam reaches higher precision, and successively, all steel protection barrels are inserted and beaten. The double-wall steel hanging box cofferdam steelprotection barrel inserting and beating accurate positioning method has good flexibility and adaptability, the positioning precision is effectively improved, a large amount of positioning time is saved, the construction cost input is reduced, and the construction period can be shortened.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

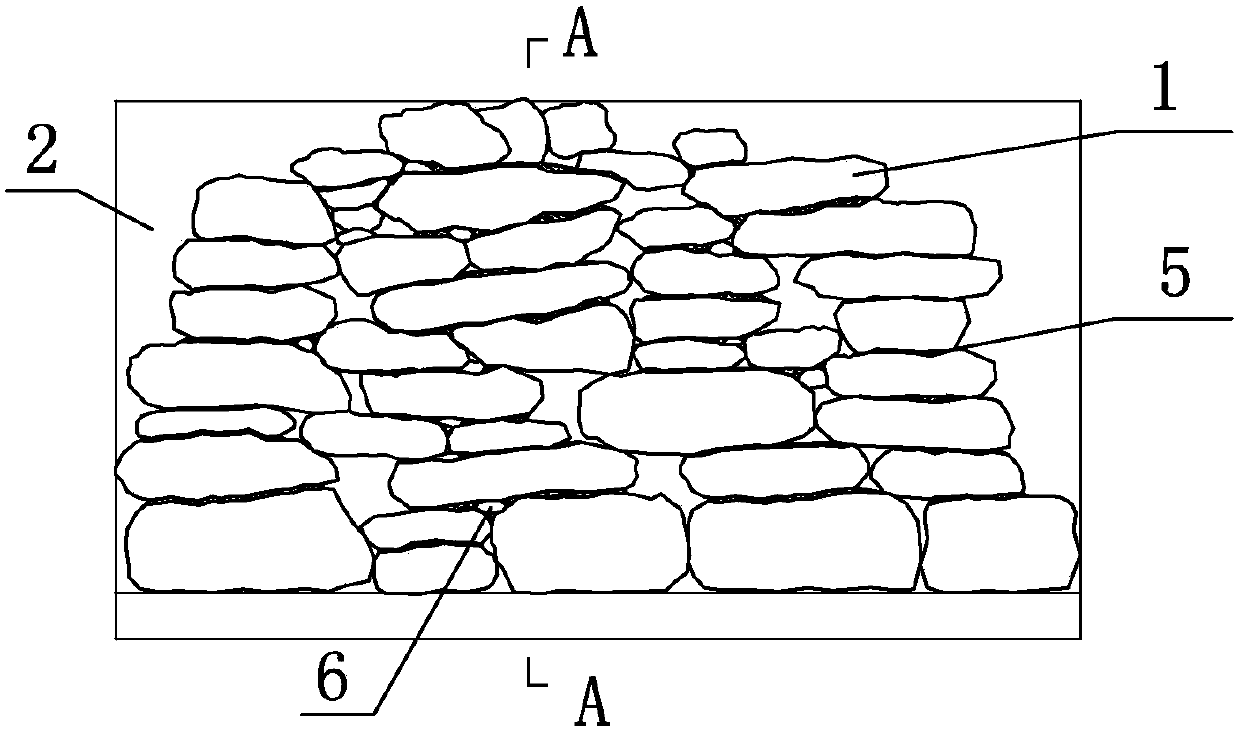

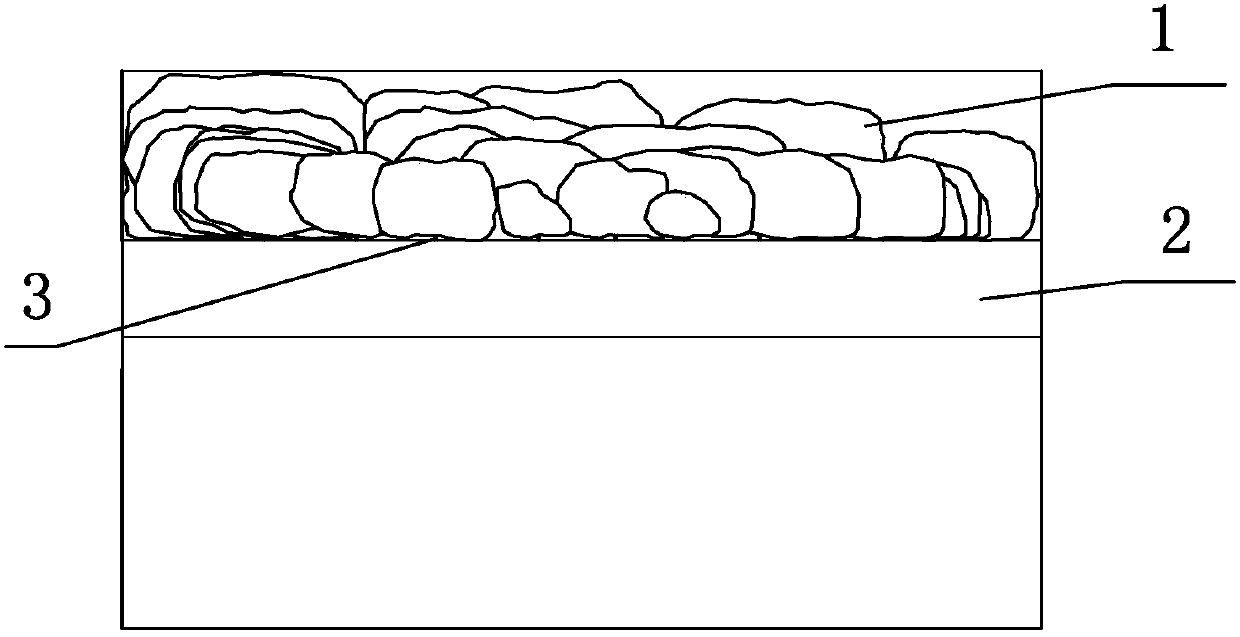

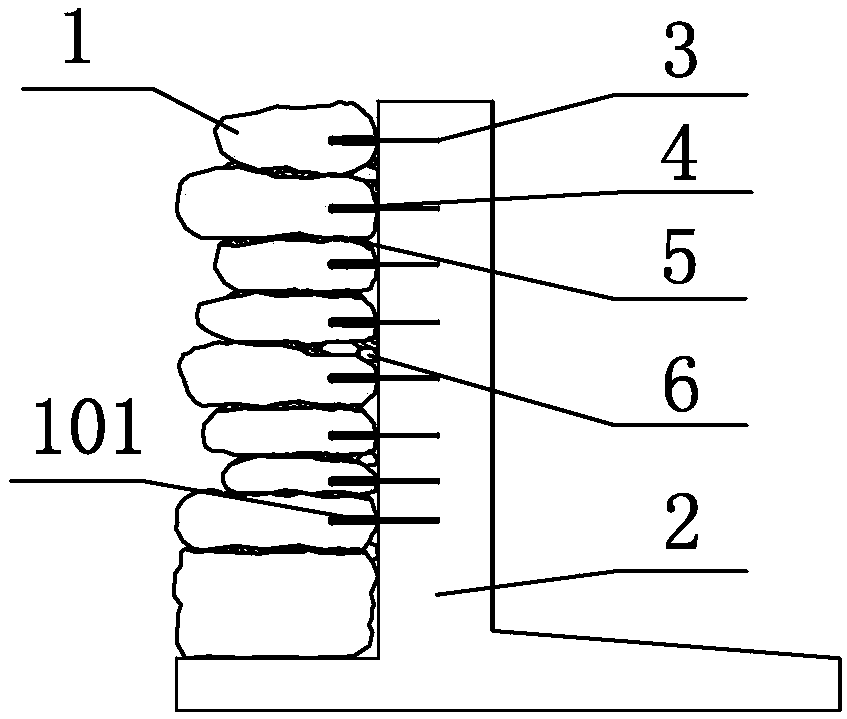

Wall-attached type mountain-row waterscape structure system and building construction method thereof

PendingCN107938829AImprove securityStable structureArtificial islandsUnderwater structuresTerrainRational use

Disclosed is a wall-attached type mountain-row waterscape structure system. The wall-attached type mountain-row waterscape structure system is formed in the mode that a cantilever type concrete retaining wall is arranged in the rugged terrain position of a river channel to serve as a foundation structure so as to form the water height difference, and rocks are arranged on the surface of the cantilever type concrete retaining wall layer by layer according to the modeling requirement to form a decorative surface. The wall-attached type mountain-row waterscape structure system comprises the multiple layers of rocks, the cantilever type concrete retaining wall and stainless steel tying pieces; the rocks are used for being arranged layer by layer according to the modeling requirement to form amain body part of a decorative surface layer of the wall-attached type mountain-row waterscape structure system, and a prefabricated hole is preformed in the middle of the top of each rock; the cantilever type concrete retaining wall and the rocks are in anchorage connection through the stainless steel tying pieces pre-embedded in the cantilever type concrete retaining wall and gelation materialsin the prefabricated holes of the rocks in an inserting mode; and the rocks of the upper layers and the rocks of the lower layers are fixed in a mortar pre-bedding mode. The wall-attached type mountain-row waterscape structure system is good in structural stability and simple and convenient in construction method, the space can be utilized reasonably, investment of the construction cost is reducedeffectively, and the water retaining and stopping effects are good.

Owner:广西建工第五建筑工程集团有限公司

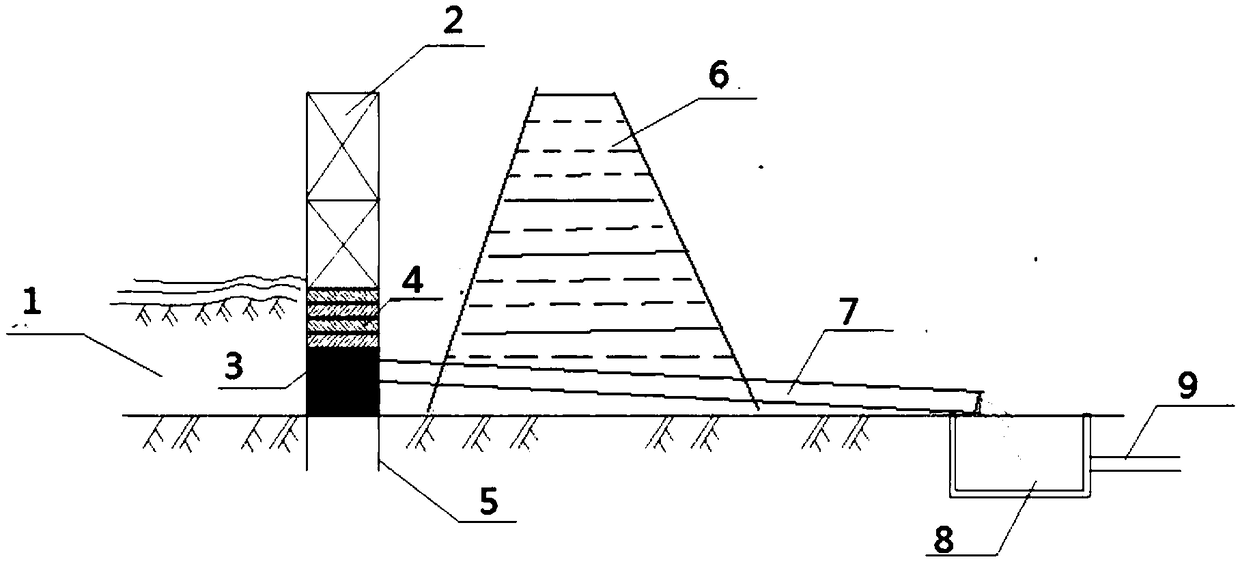

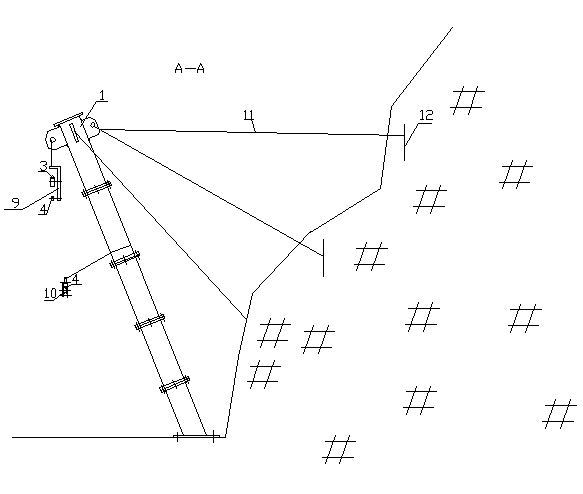

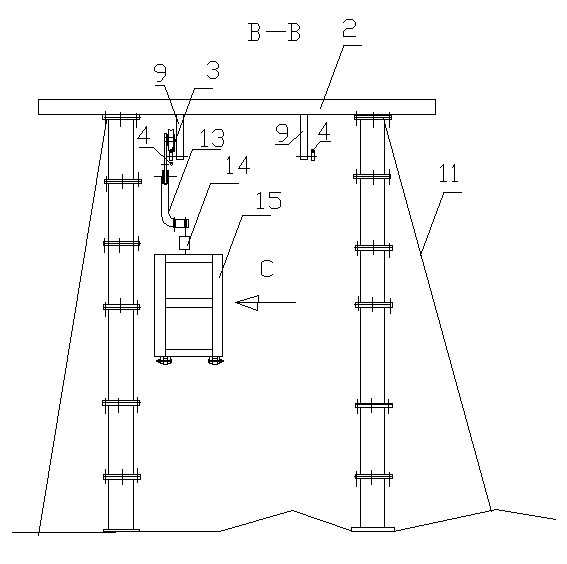

Water recession system adopting steel-structure derrick-type water recession opening and construction method thereof

PendingCN108824348AReduce security risksEasy to operateBarrages/weirsHydraulic engineering apparatusBrickArchitectural engineering

The invention discloses a water recession system adopting a steel-structure derrick-type water recession opening. The water recession system mainly comprises a groove steel frame, fenders, a water recession pipe, an energy dissipation pool and a water recession canal. The groove steel frame is a vertical column frame formed in the mode that groove steel is fixed through horizontal supports and scissor supports; a water tank is arranged on the groove steel frame, and groove steel of 1 m is reserved at the bottom end of the water tank; the fenders are arranged in a groove steel groove of the portion, above the water tank, of the groove steel frame; one end of the water recession pipe is inserted into an opening hole, and the other end of the water recession pipe penetrates through a cofferdam and extends into the energy dissipation pool; and the side, away from the cofferdam, in the energy dissipation pool is provided with the water recession canal. The water recession system adopting the steel-structure derrick-type water recession opening is easy to manufacture and mount, conventional materials such as bricks, concrete and cement are not used, the complicated construction process of a traditional water recession opening is omitted, the construction schedule is accelerated, construction cost input is lowered, and the safety risk is low.

Owner:安徽建工路港建设集团有限公司

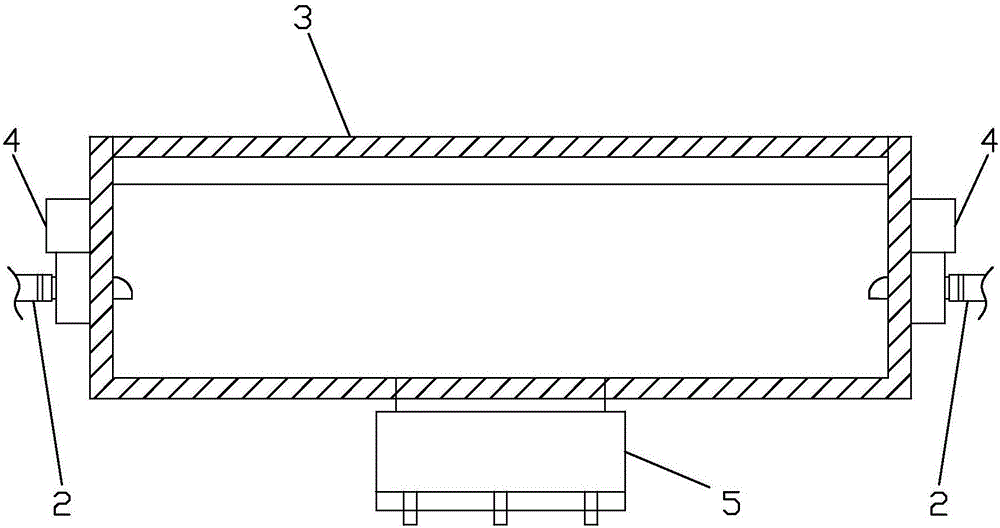

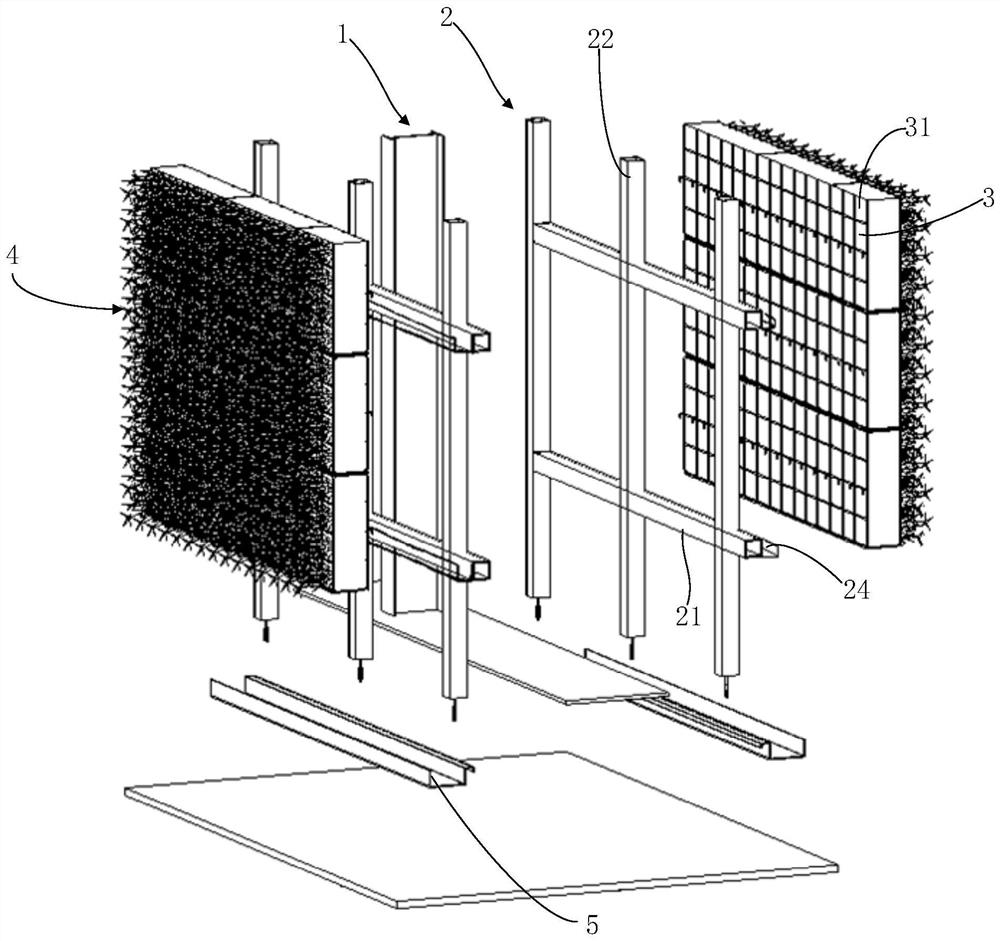

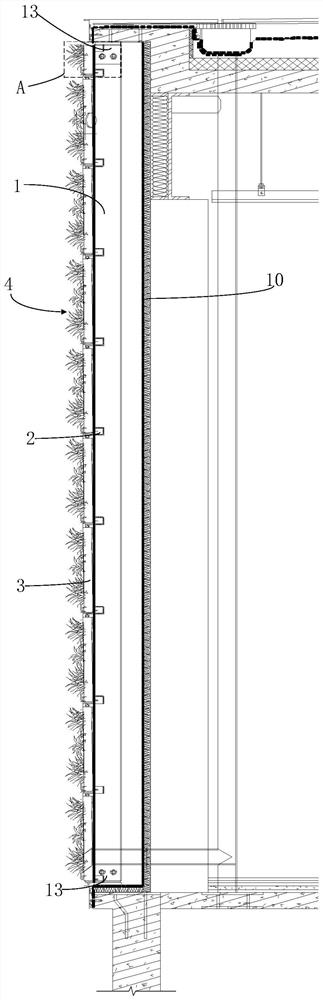

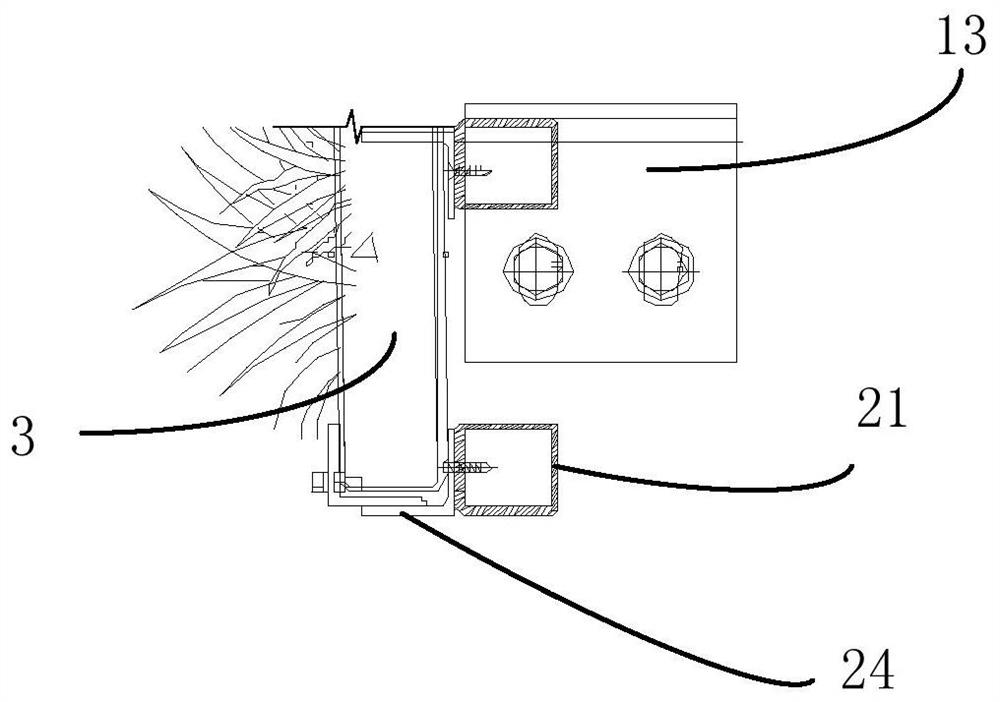

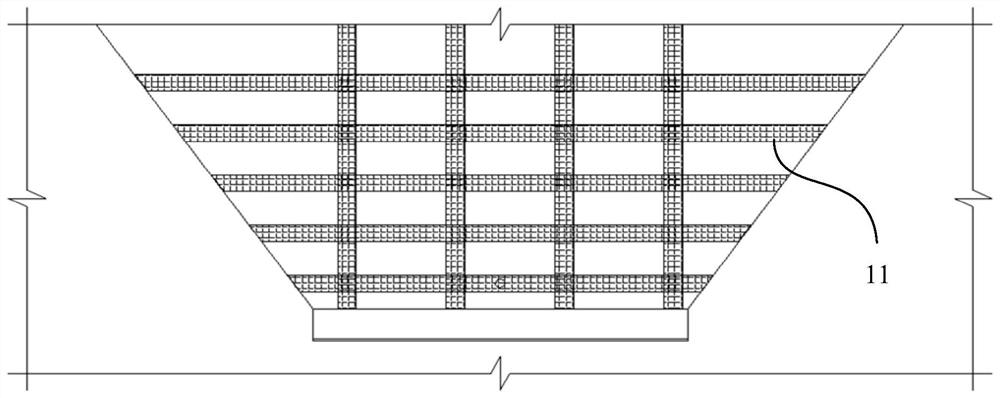

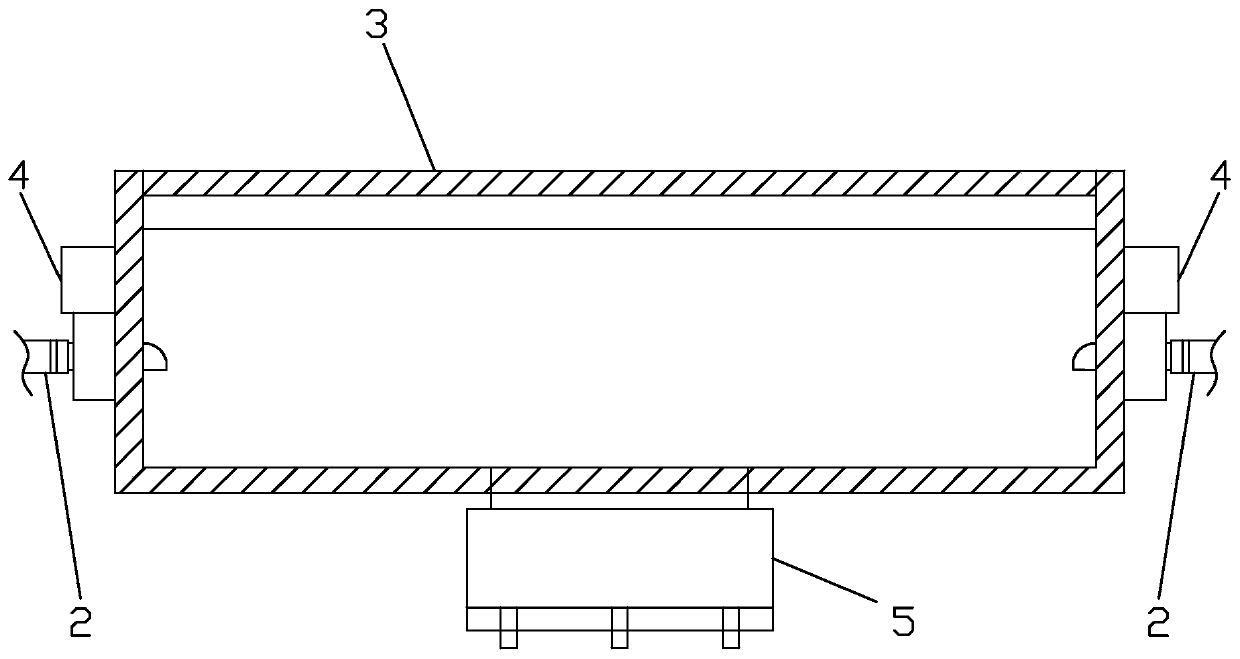

Modular planting system structure for vertical greening of wall surface and construction method thereof

PendingCN113383660AReduce the chance of sheddingGuarantee safety and reliabilityCultivating equipmentsReceptacle cultivationAgricultural engineeringGreening

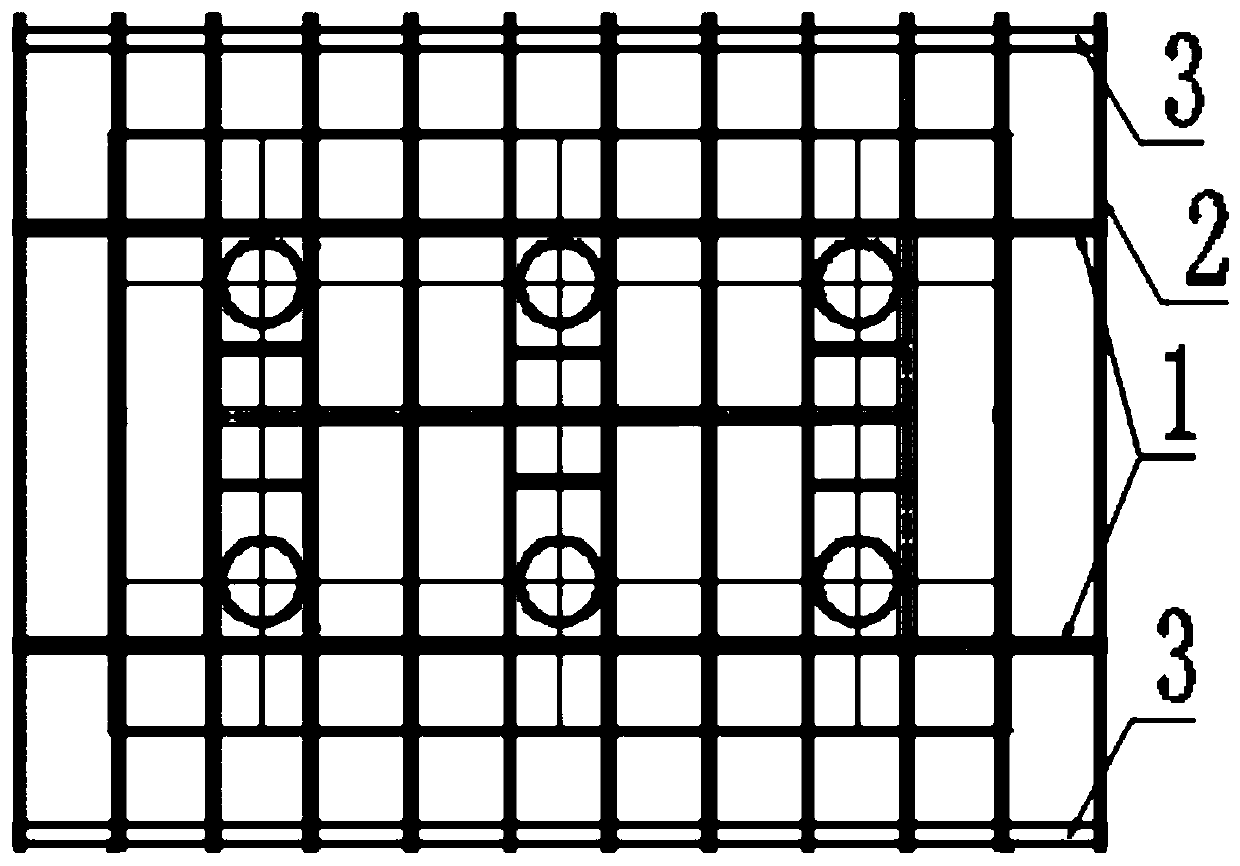

The invention provides a modular planting system structure for vertical greening of a wall surface and a construction method thereof. The modular planting system structure for vertical greening of the wall surface comprises a fabricated net rack, planting boxes, planting barrier soil blocks and planting bags, wherein the fabricated net rack is fixed to the side wall of the wall surface through a main bearing keel, the fabricated net rack comprises a plurality of transverse rods and vertical rods, and the transverse rods and the vertical rods are connected in a transversely and longitudinally staggered mode to form a plurality of planting groove blocks; the planting boxes can be opened and closed and are fixed to the planting groove blocks in a one-to-one correspondence mode; the planting barrier soil blocks are embedded and fixed in the planting boxes; each planting bag is provided with a through opening suitable for an opening of the corresponding planting box, the planting bags are fixed to the fabricated net rack and hangs and covers the planting boxes, and the through openings corresponds to the openings of the planting boxes. According to the modular planting system structure for vertical greening of the wall surface, the vertical greening type forms of existing buildings can be increased, meanwhile, the falling probability can be reduced, and the safety and reliability of a green plant wall are guaranteed.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

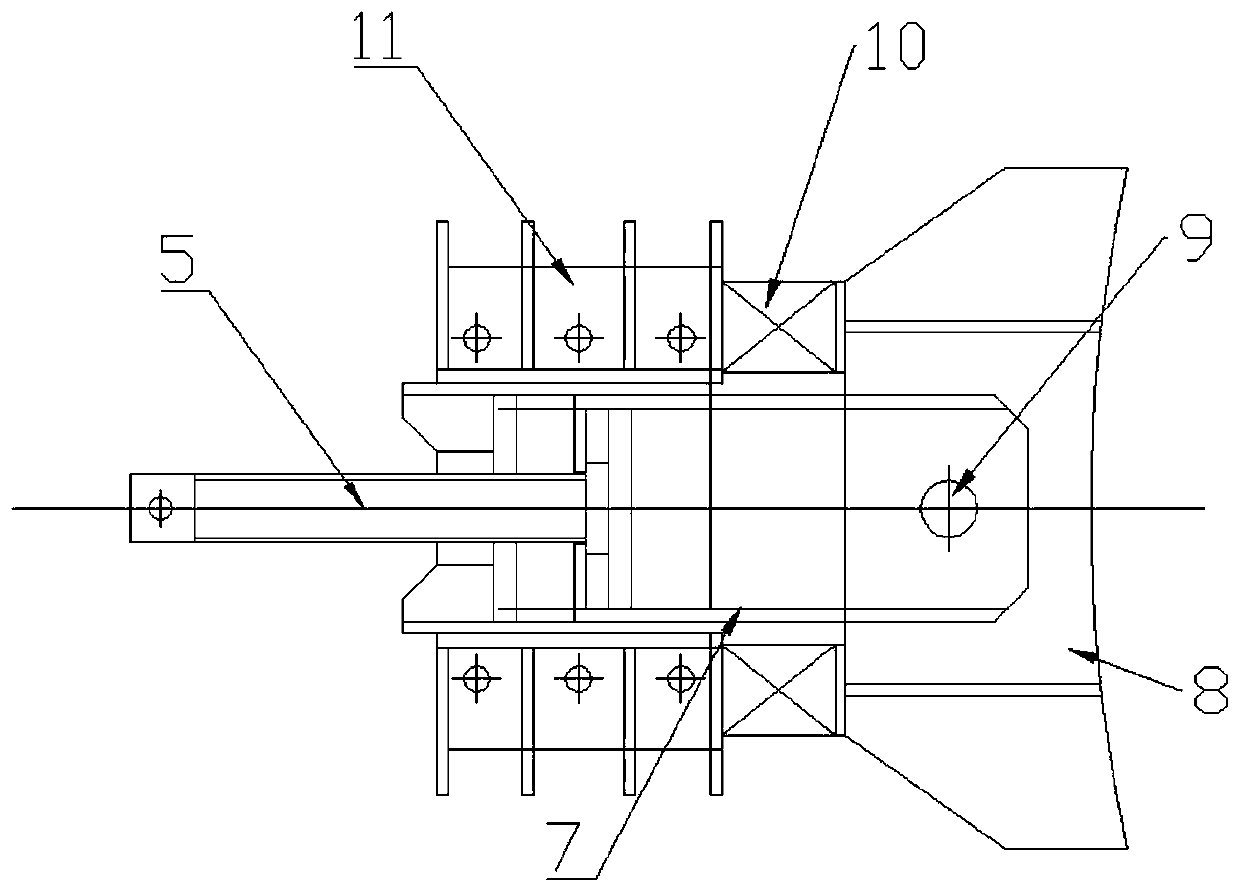

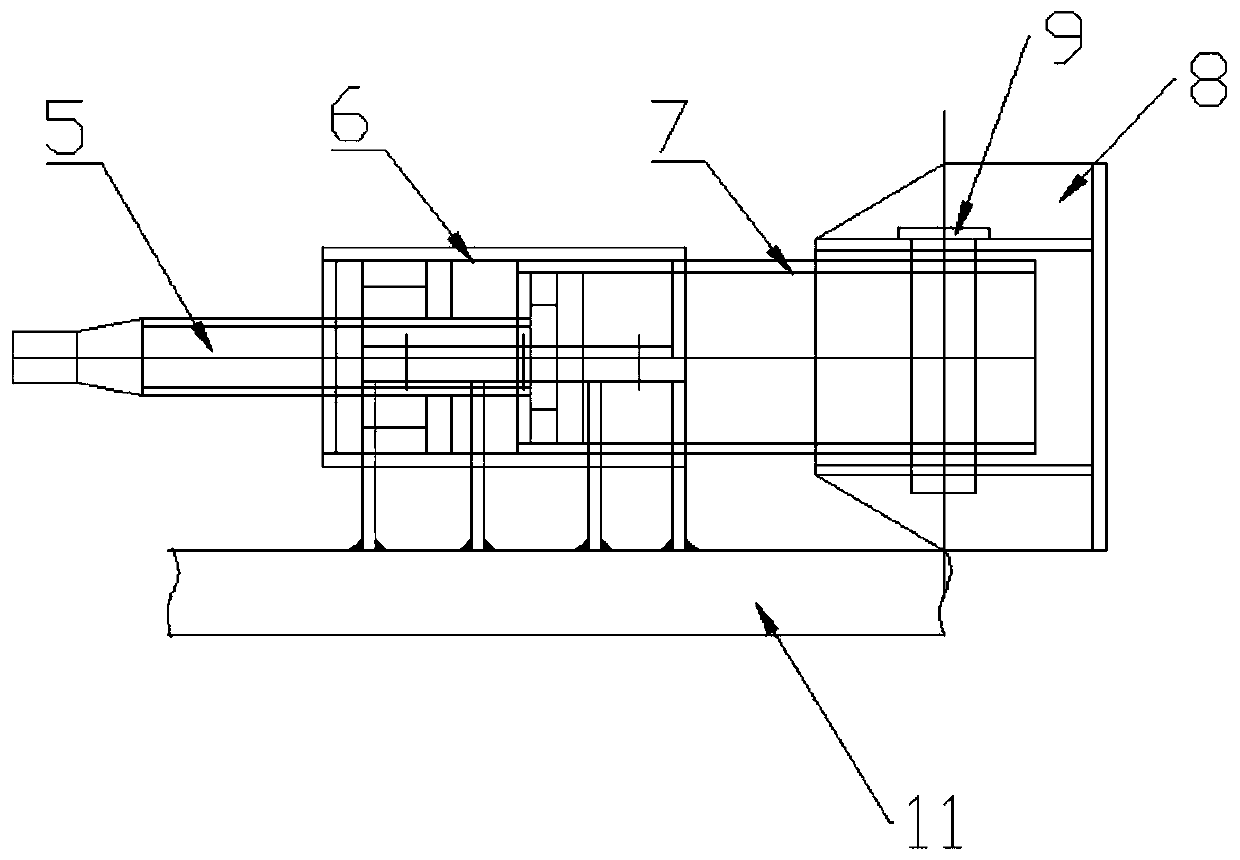

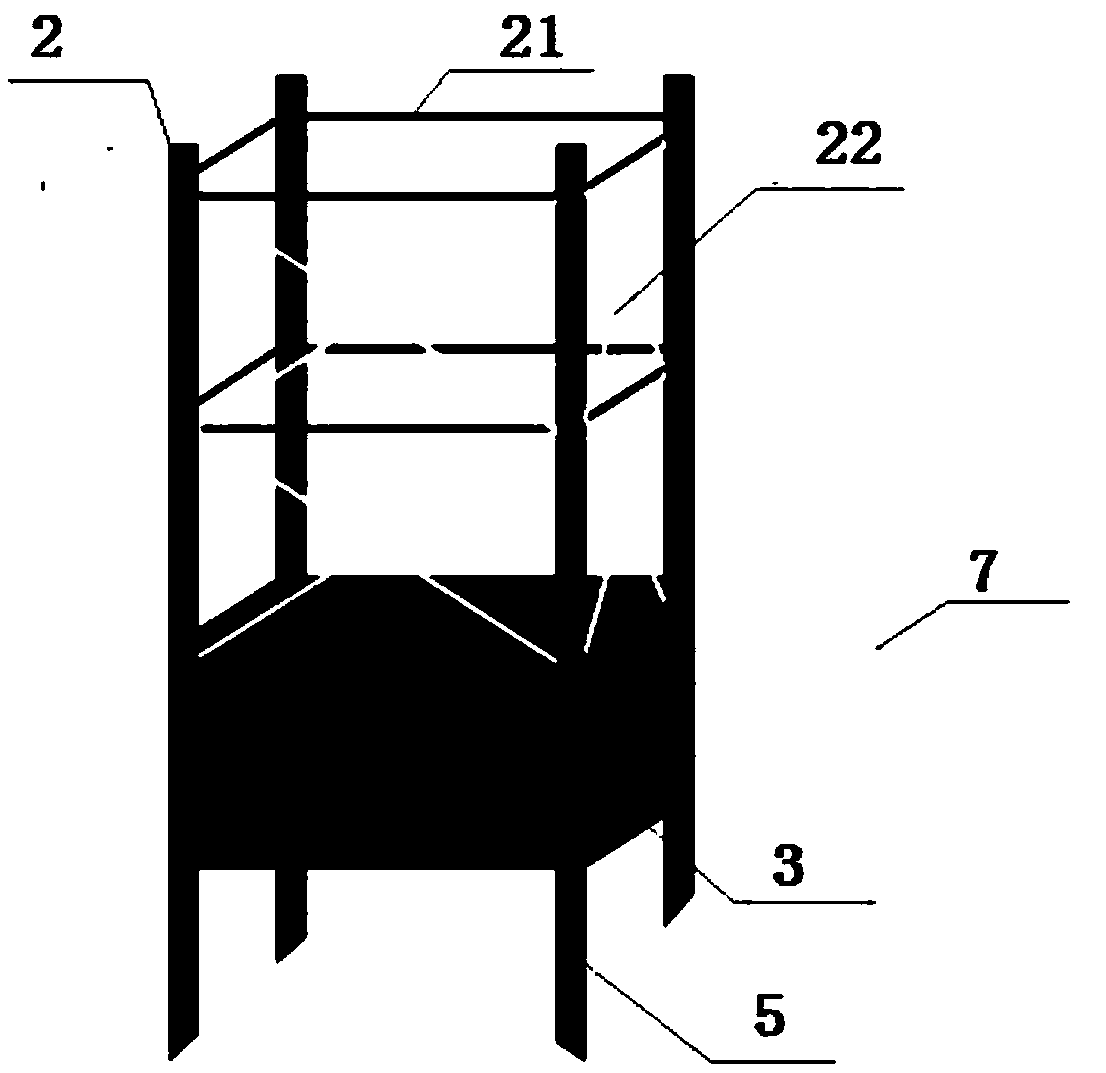

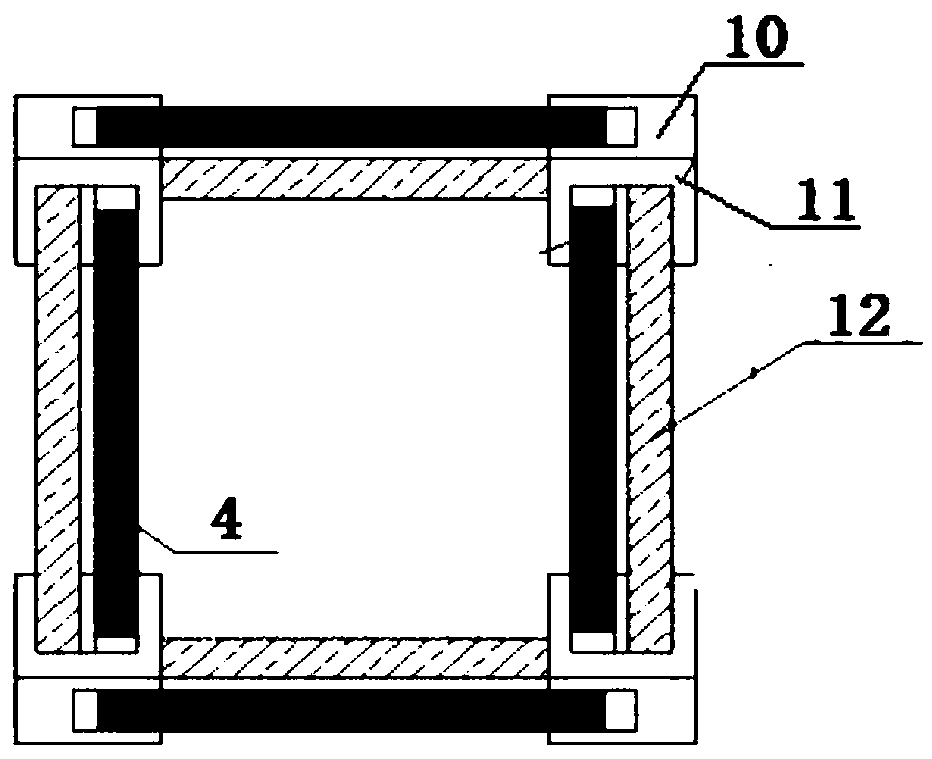

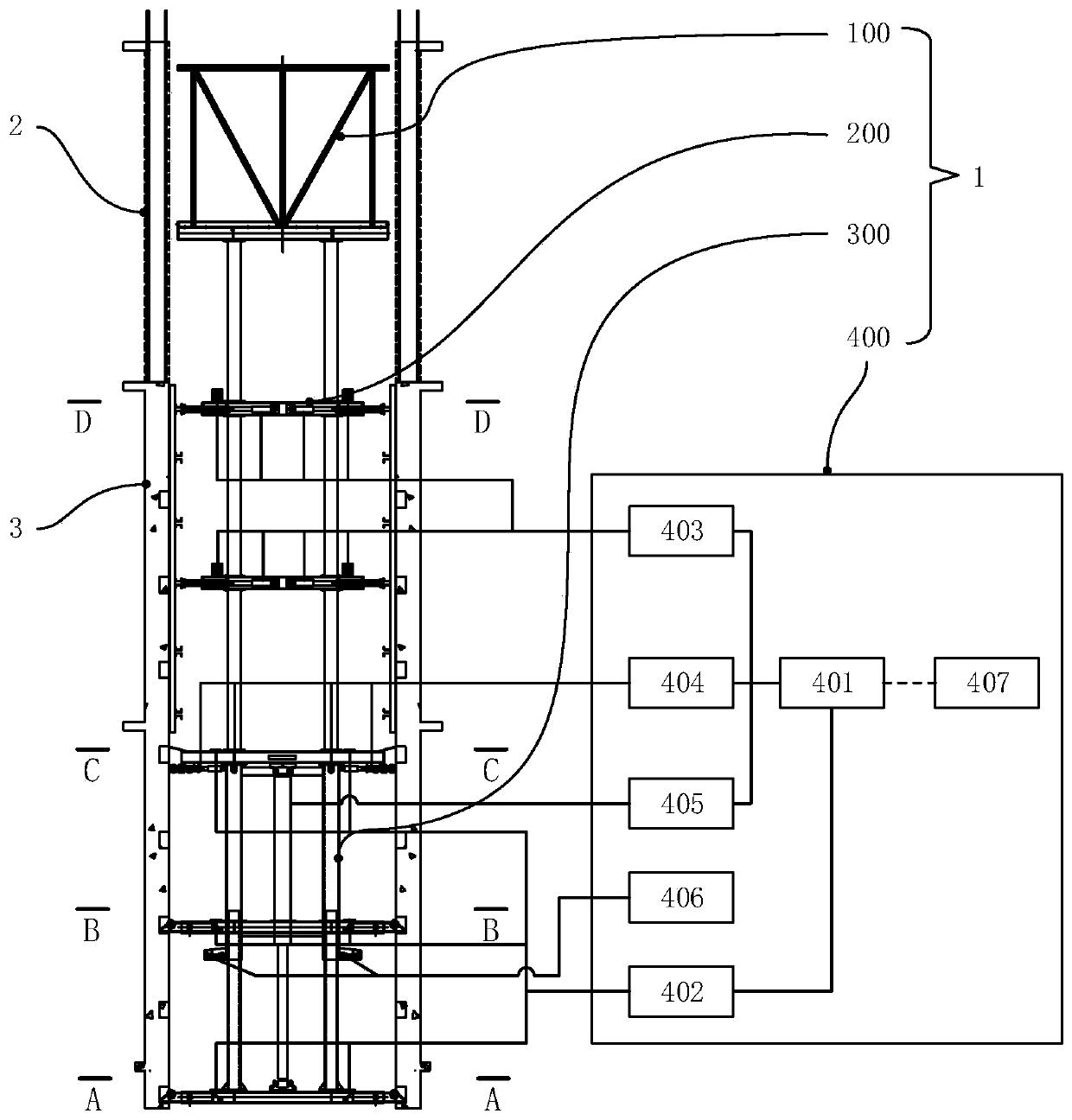

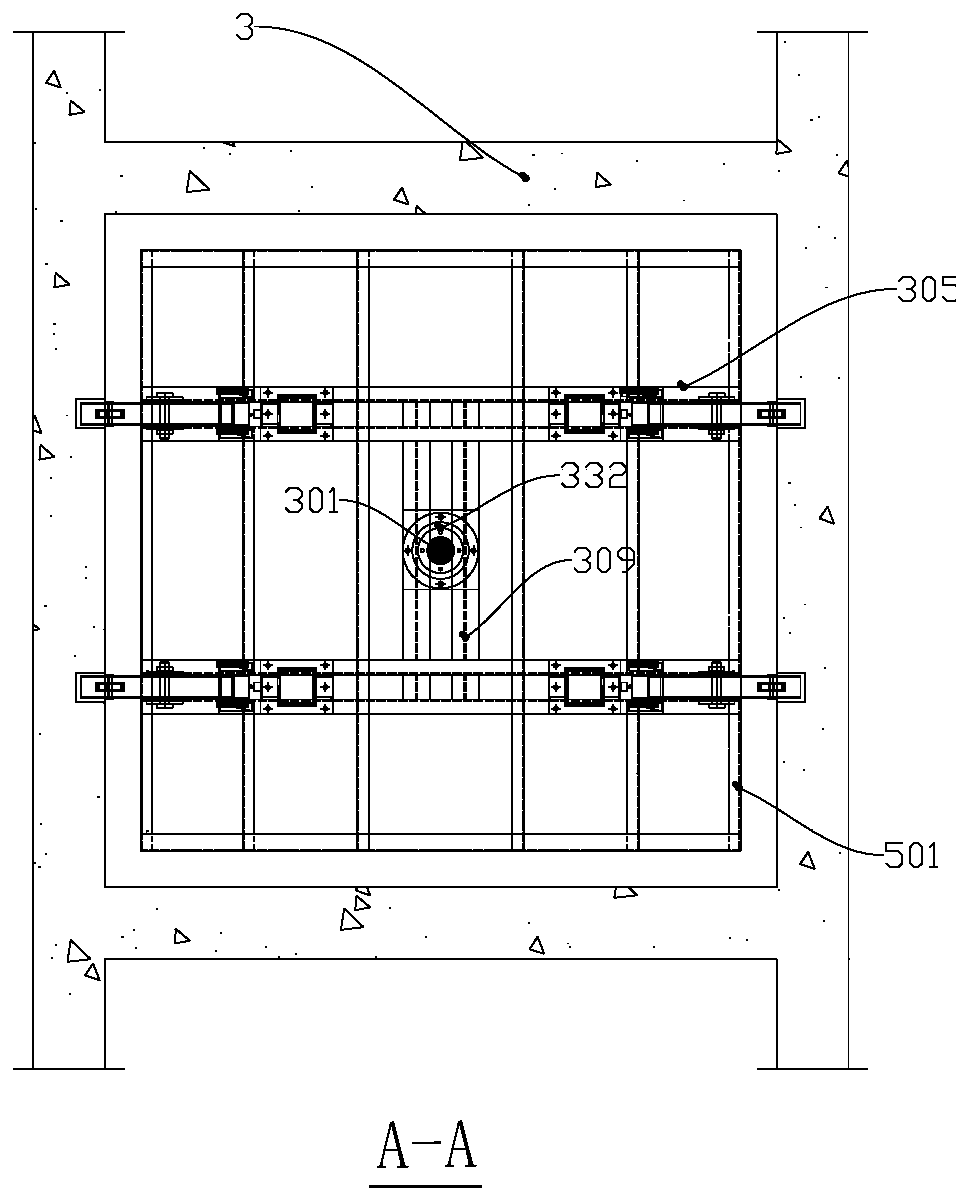

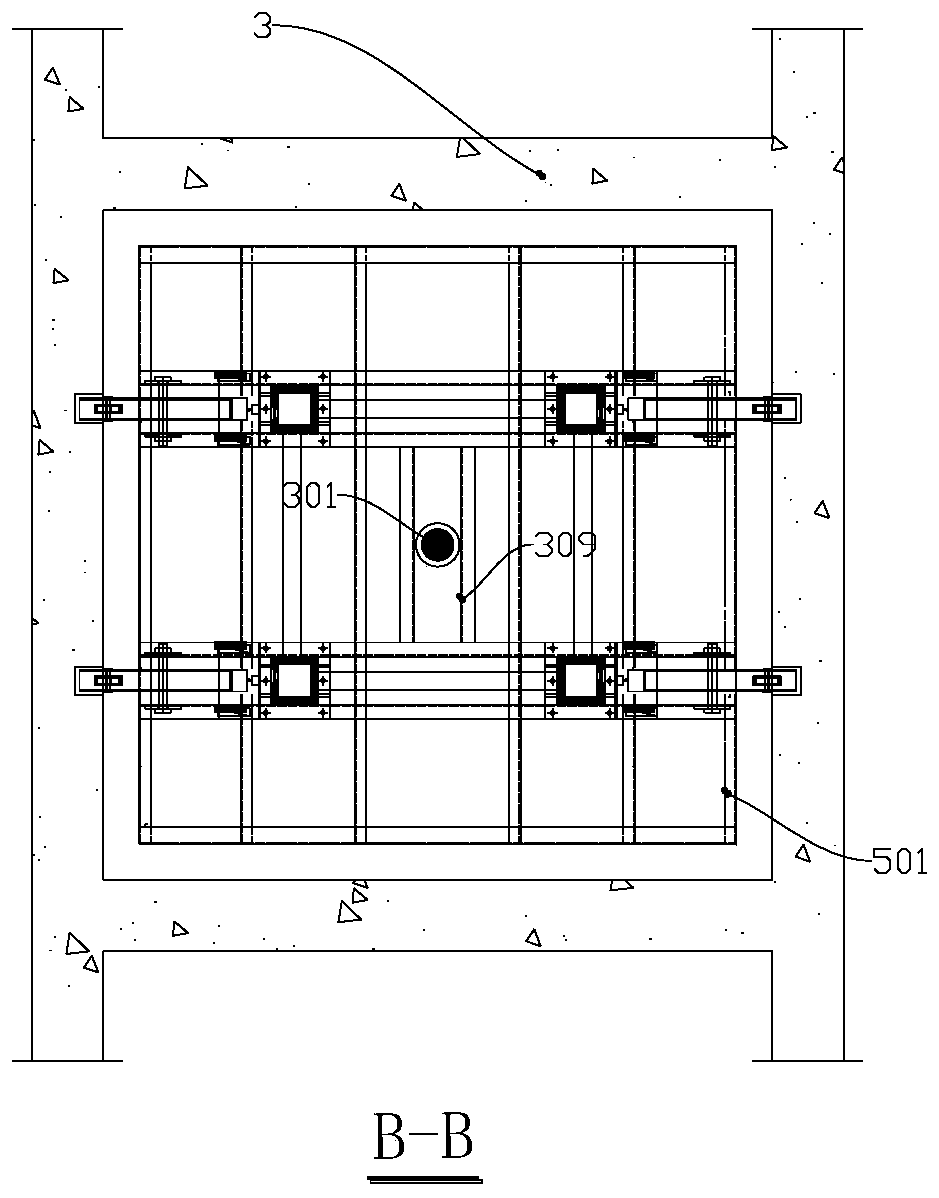

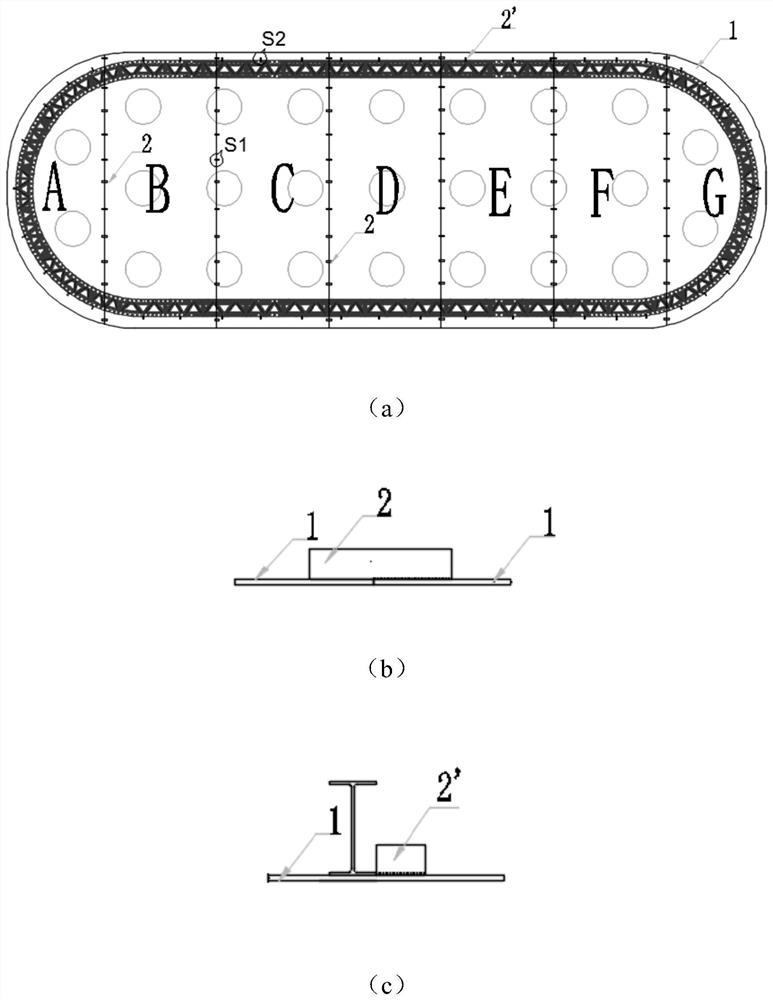

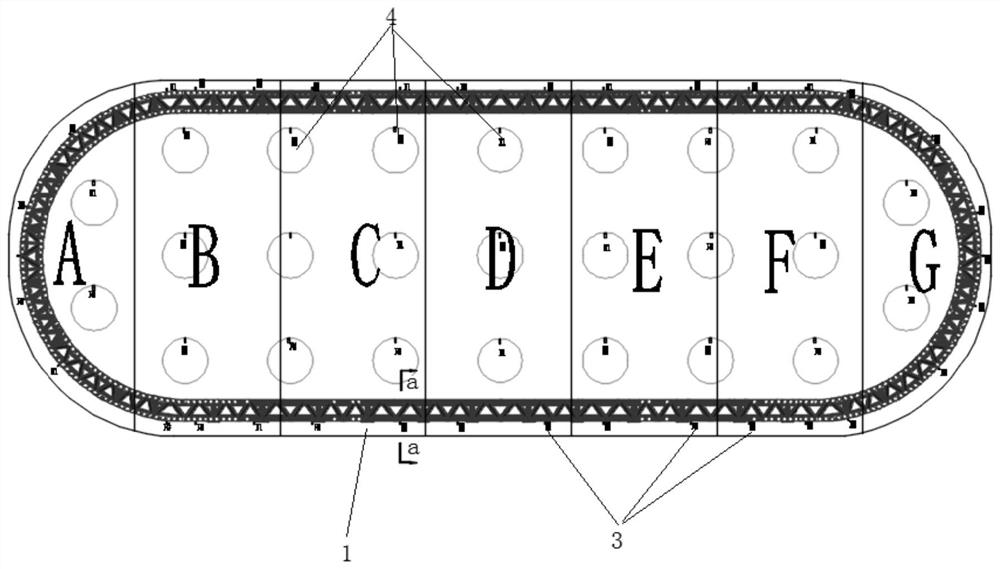

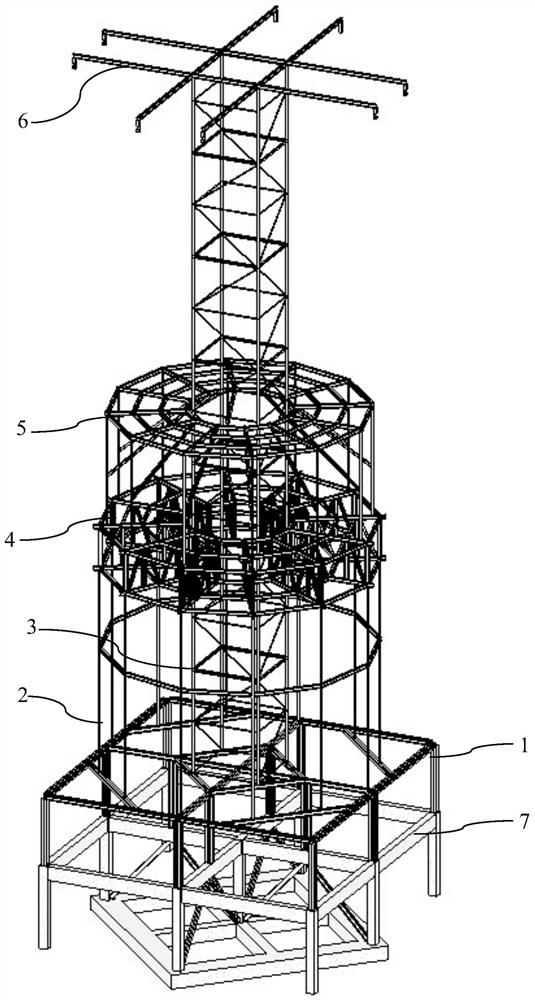

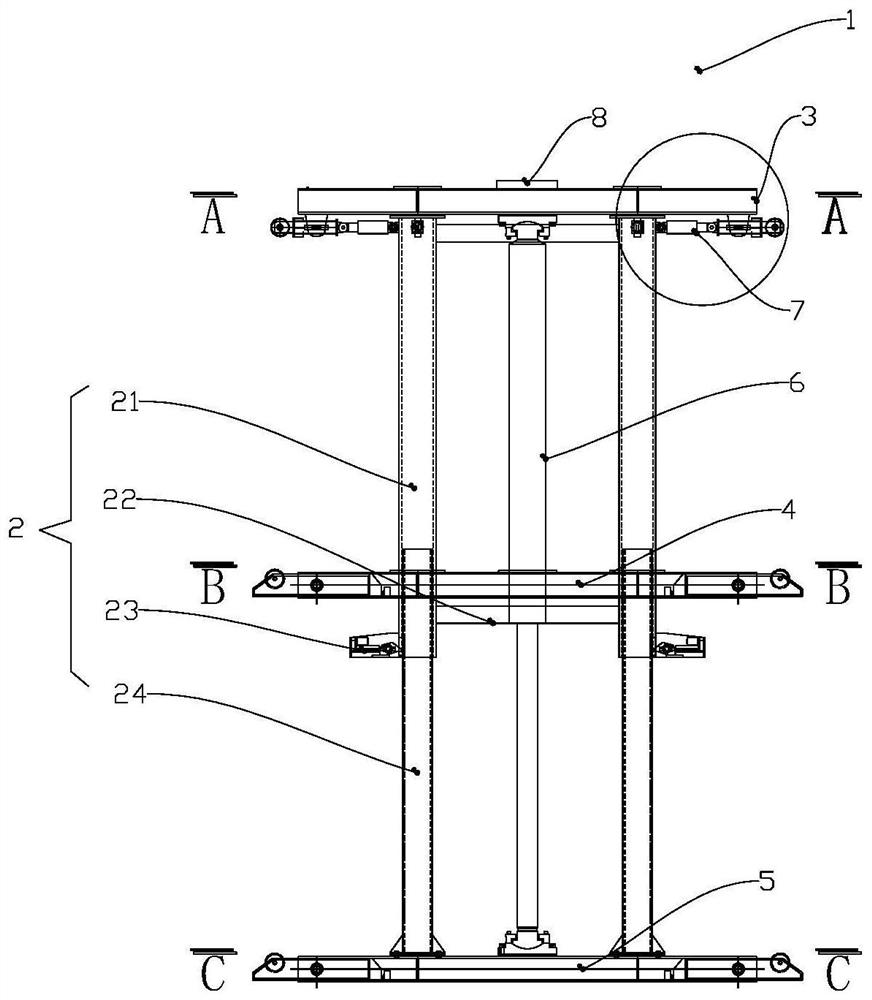

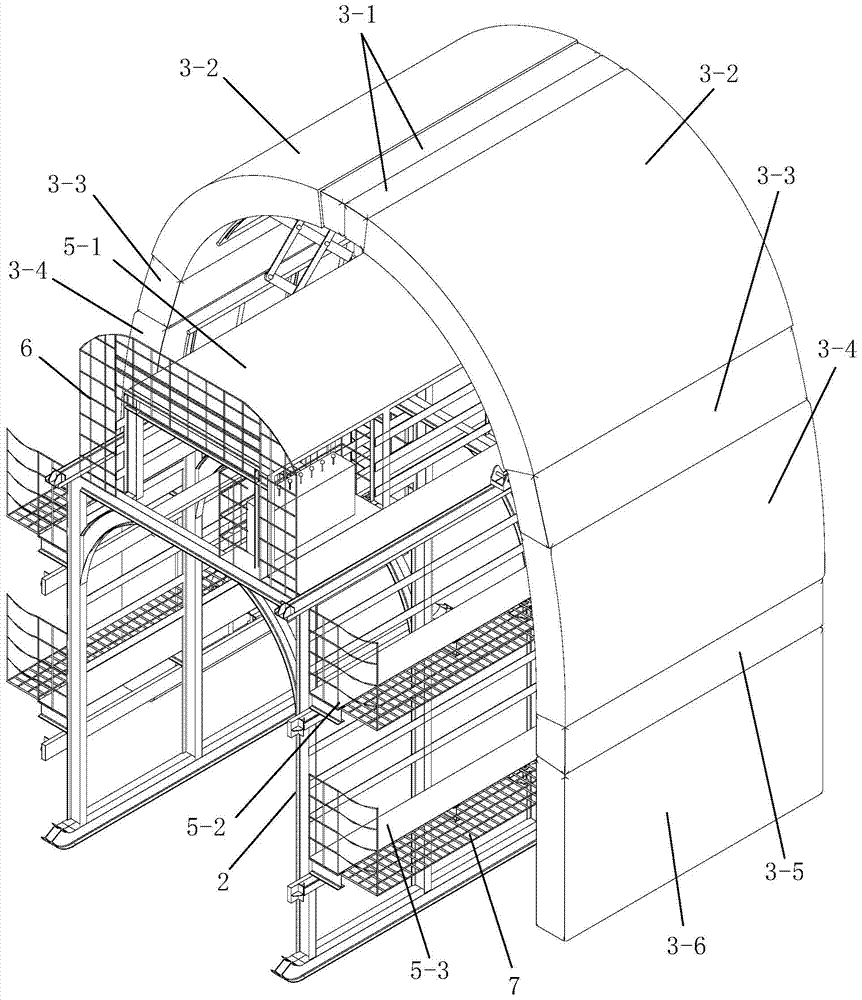

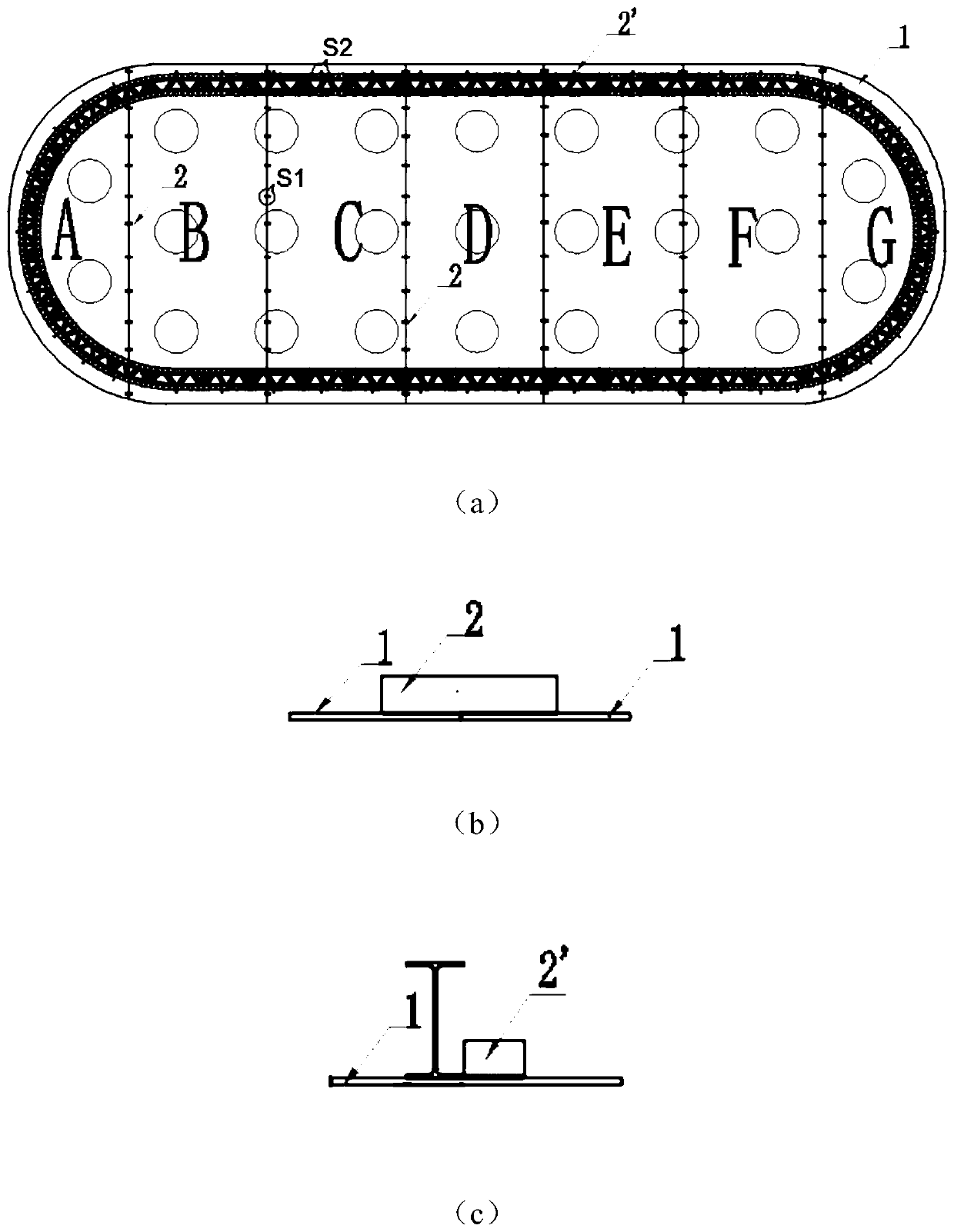

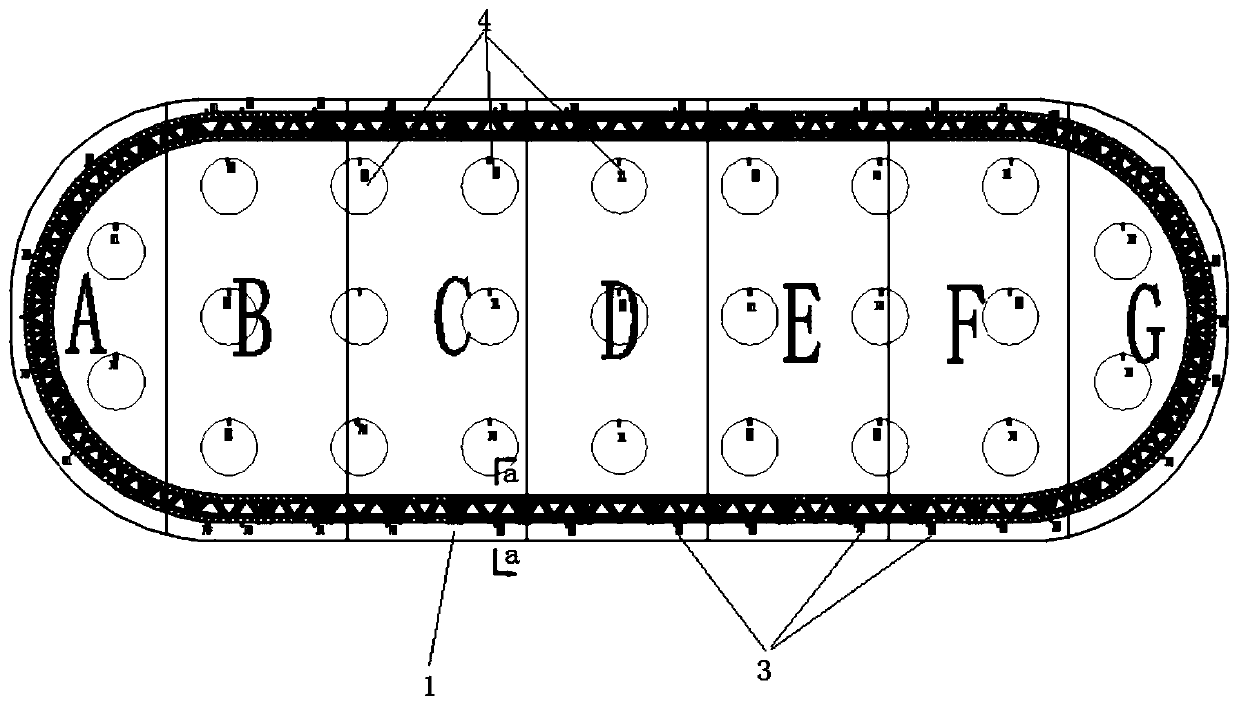

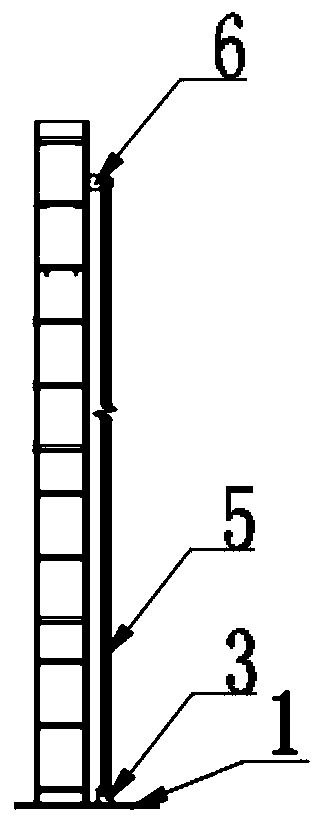

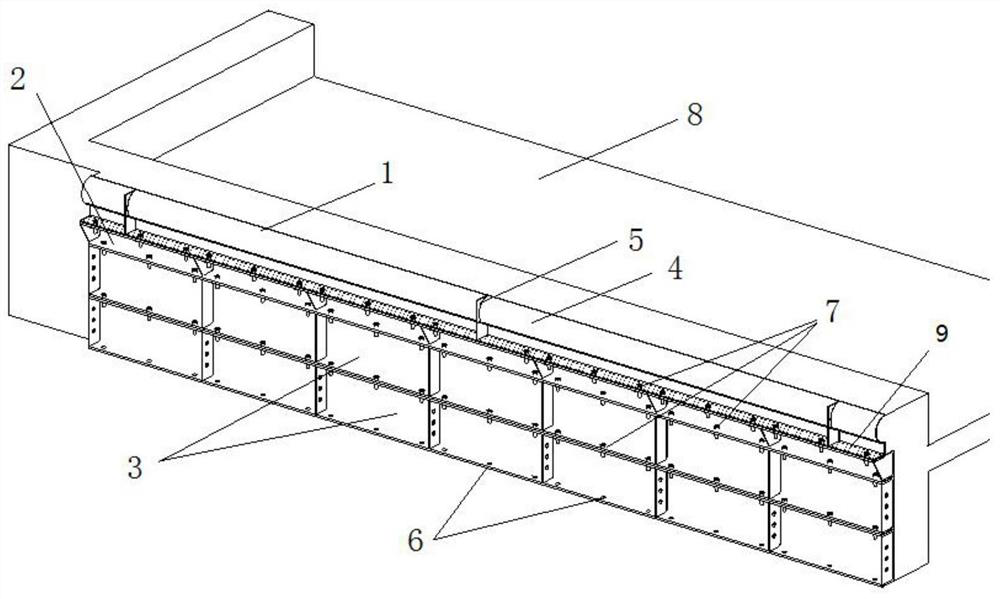

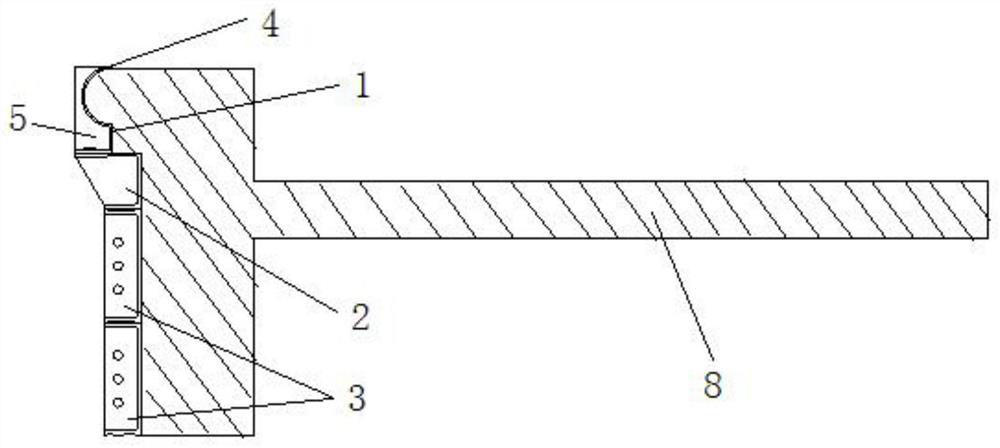

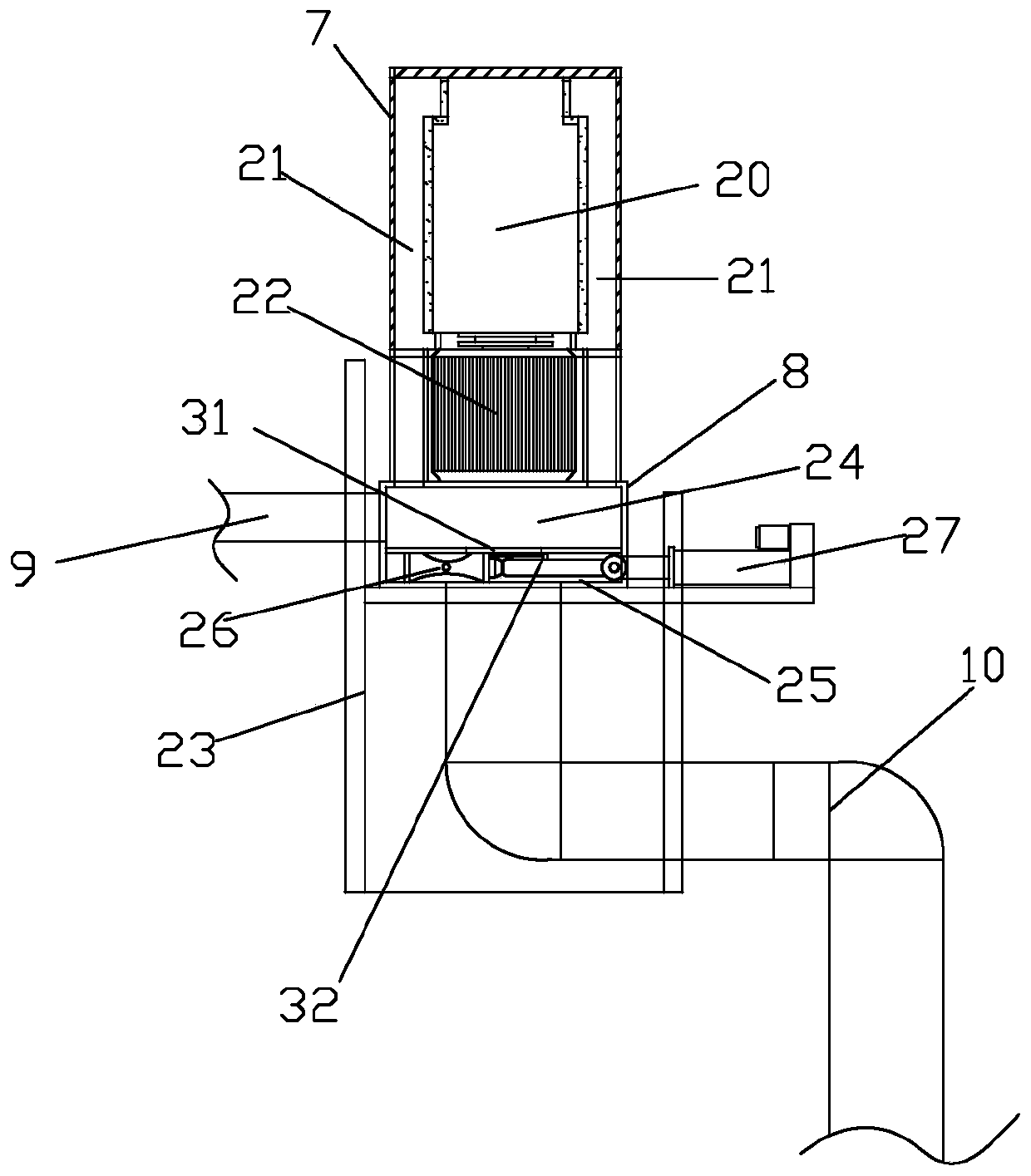

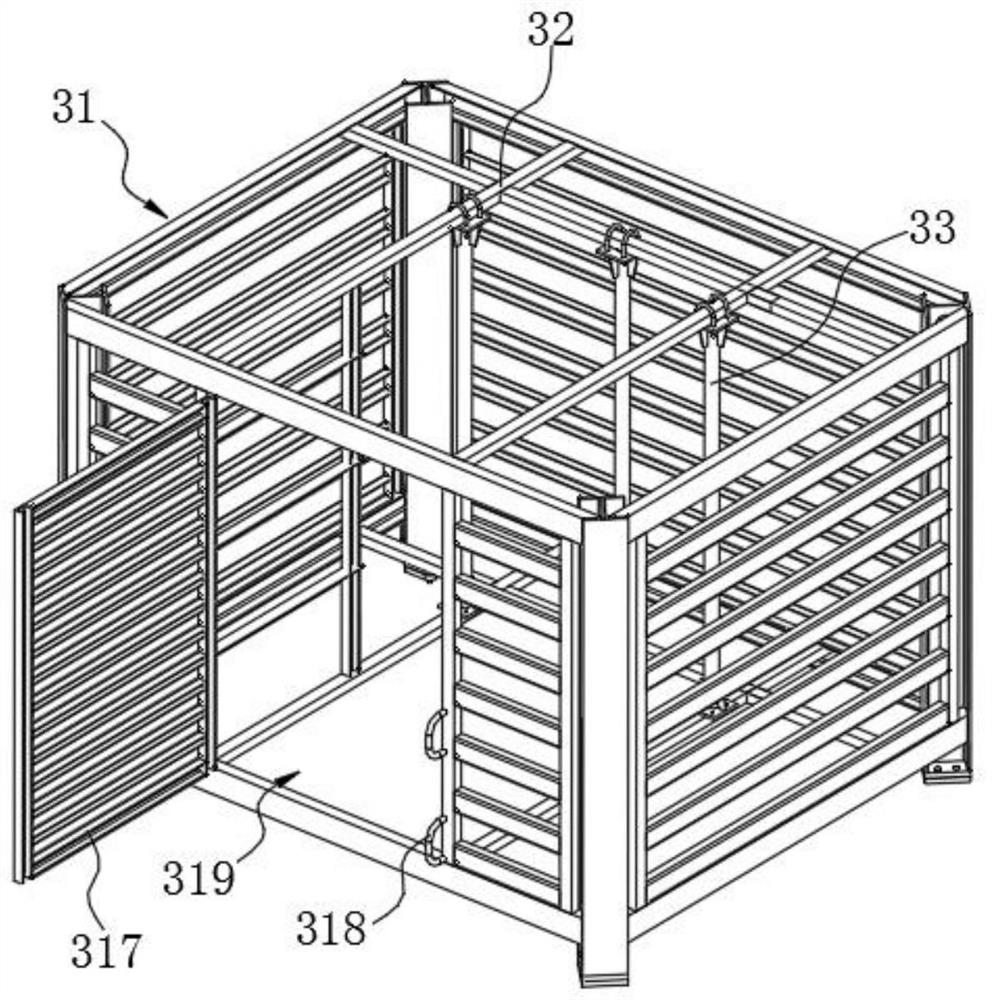

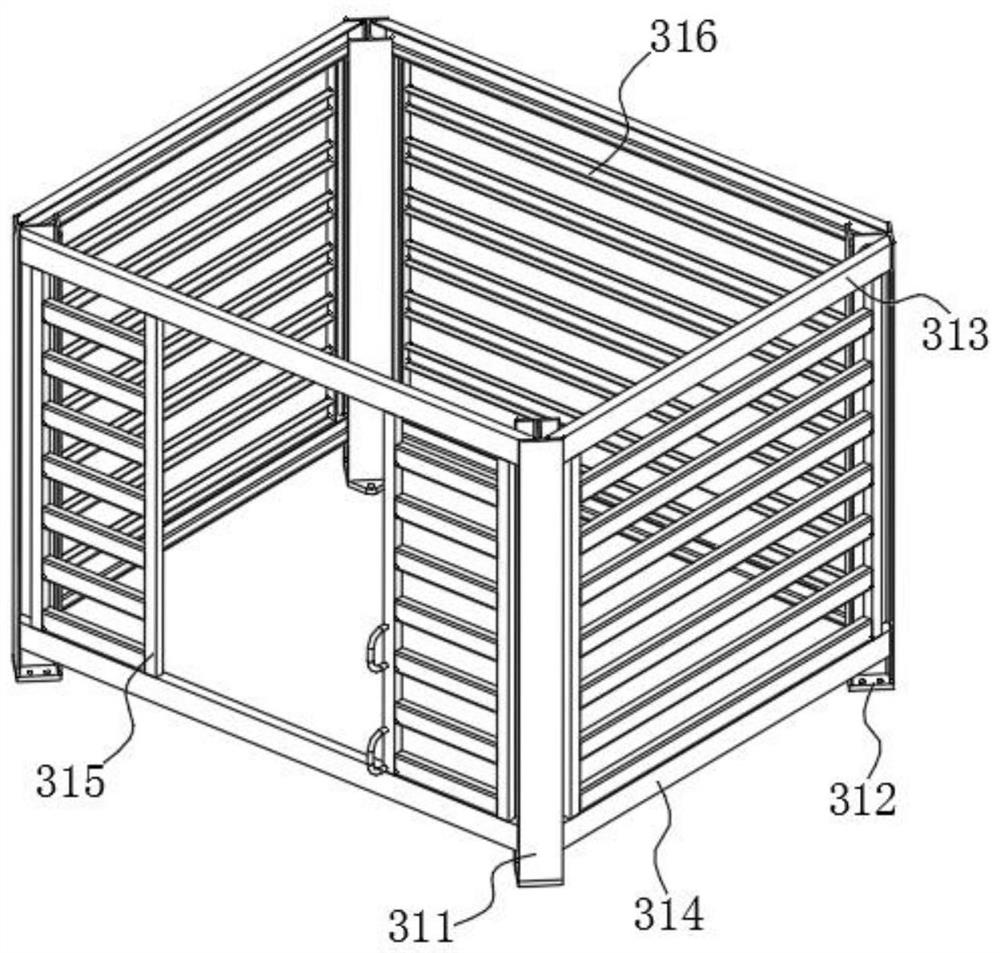

Automatic jacking cylinder frame formwork system for concrete structure construction and method thereof

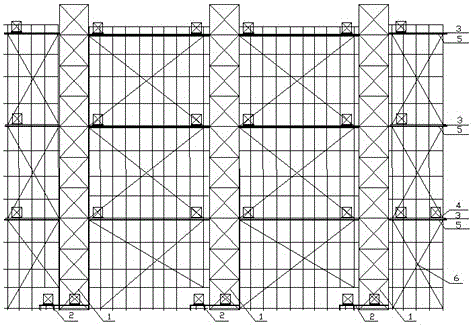

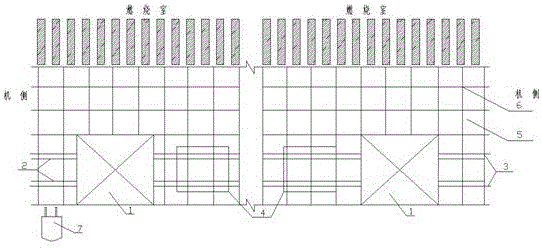

ActiveCN111058617AReliable space work platformStable space work platformForms/shuttering/falseworksAutomatic controlBraced frame

The invention belongs to the technical field of constructional engineering construction, particularly relates to an automatic jacking cylinder frame formwork system for concrete structure constructionand a method thereof, and aims to solve the problems of many potential safety hazards and low climbing efficiency in a traditional construction process during construction of concrete cylinder structures of high-rise and super high-rise buildings. The device comprises a formwork operation system, a steel bar operation frame, a sleeve frame jacking system and a control system; the formwork operation system comprises stand columns, a formwork opening and closing device and a shaping formwork, and connecting plates are arranged at the upper ends and the lower ends of the stand columns; the steelbar operation frame comprises a plurality of profile steel rod pieces and bottom connecting beams which form a steel frame structure together with the stand columns, the sleeve frame jacking system comprises a jacking oil cylinder telescopic sleeve frame, a horizontal jacking frame, an upper supporting frame, a lower supporting frame and a plurality of longitudinal connecting beams; and the automatic control system is used for intelligently controlling full-automatic opening and closing of a formwork and full-automatic climbing of a jacking cylinder frame formwork.

Owner:SHANGHAI CONSTRUCTION GROUP

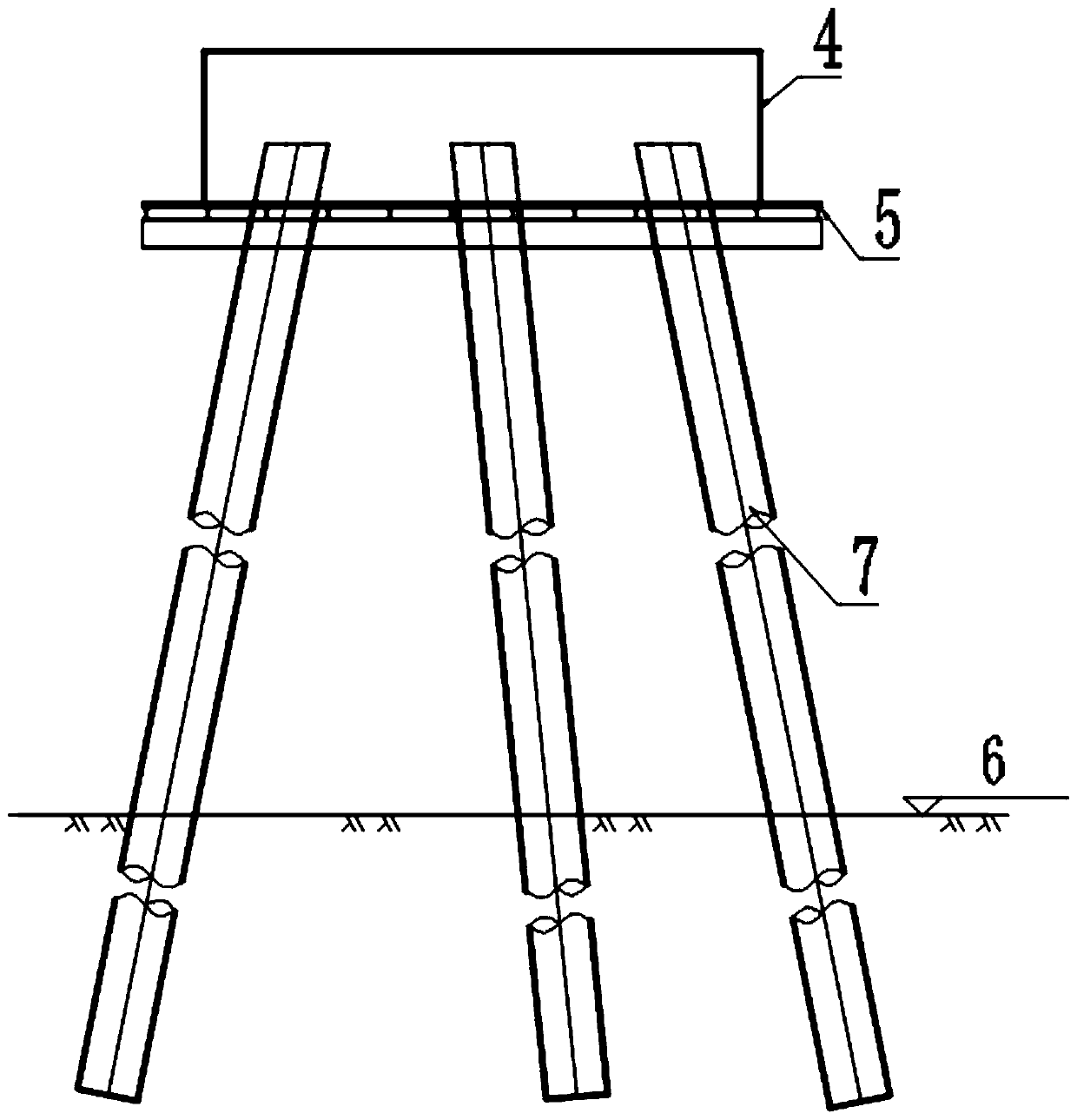

Rapid construction method for underwater isolated pier support platform

InactiveCN110939063AEasy constructionConstruction safetyBridge structural detailsBridge erection/assemblyArchitectural engineeringStringer

The invention discloses a rapid construction method for an underwater isolated pier support platform. Inserting and driving of inclined steel pipe piles in water and manufacturing of a platform support on land are conducted at the same time. The platform support is mainly composed of cross beams and longitudinal beams. The platform support is hoisted to the inclined steel pipe piles through hoisting equipment, and welded and reinforced; and concrete is poured on the platform support, and anchorage pier manufacturing is completed. The method is simple in construction, safe and rapid, and smoothconstruction is guaranteed; and the labor investment and working hours can be reduced, the construction cost investment is effectively reduced, and the construction period is shortened.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

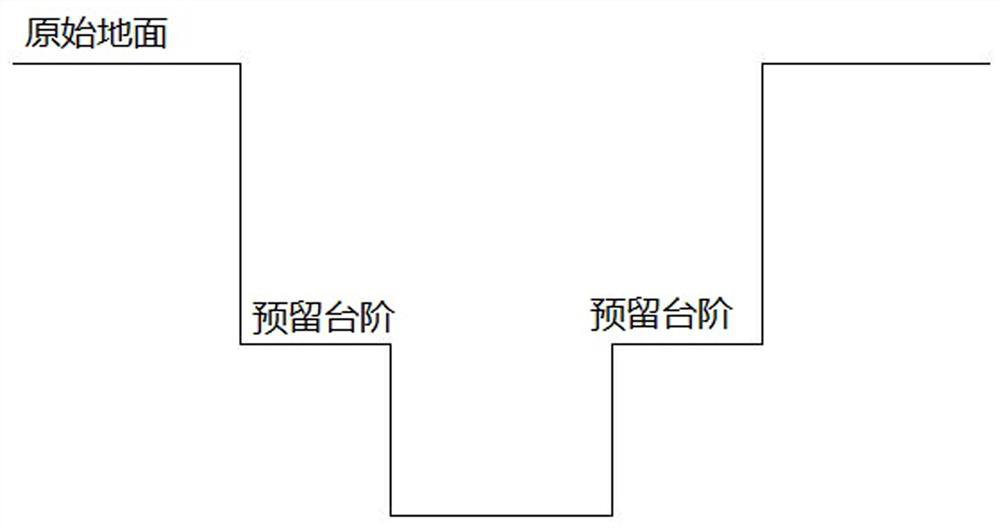

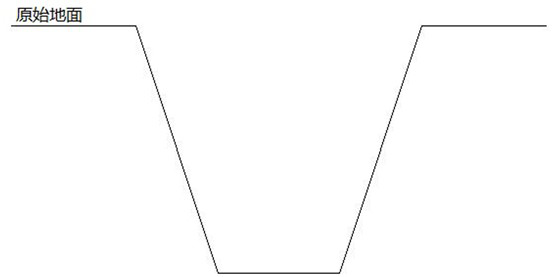

Method for excavating and supporting deep and narrow pipe ditch under complex conditions

ActiveCN113684839AGuarantee the quality of supportEnsure safetySoil-shifting machines/dredgersExcavationsArchitectural engineeringDitch

The invention belongs to the technical field of civil engineering and municipal engineering, and particularly relates to a method for excavating and supporting a deep and narrow pipe ditch under complex conditions. The construction technological process comprises the steps of current situation investigation, exploration pit excavation, pipe ditch excavation, reserved earth ridge parameter determination, reserved earth ridge excavation construction and pipe ditch supporting completion. According to the method for excavating and supporting the deep and narrow pipe ditch under the complex conditions, rapid construction of the deep and narrow pipe ditch can be achieved on the premise that the excavation and supporting quality of the deep and narrow pipe ditch is guaranteed, the construction period is shortened, and the construction cost input is reduced. The method for excavating and supporting the deep and narrow pipe ditch under the complex conditions is particularly suitable for excavation and supporting construction of the deep and narrow pipe ditch, and the excavation and supporting construction method of the deep and narrow pipe ditch is optimized and adjusted according to the design under the condition that the quality requirement is guaranteed to be met.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

A block-by-block salvage method for a large bottom supporting plate in the river as a whole

ActiveCN111021360BGoing down the river is safe and smoothReduce demandFoundation engineeringBridge erection/assemblyIndustrial engineeringPallet

The invention discloses a block-by-block salvage method for a large bottom supporting plate in the river as a whole. The large bottom supporting plate is divided into blocks, and each block is spliced together through a connecting structure, and then connected with a large steel structure to form a whole. The structure realizes stable self-floating, cuts off the connection with the large steel structure, uses the self-weight of the large bottom supporting plate to break the splicing structure between each block, and realizes the automatic division and salvage of the large bottom supporting plate underwater. The invention does not need large-scale salvage equipment and divers to operate, realizes rapid recovery and recycling, has high safety and economy, reduces labor input and working hours, effectively reduces construction cost input and shortens construction period.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Repair method for existing industrial factory building production equipment

PendingCN113821854AKeep the industrial styleImprove securityGeometric CADDesign optimisation/simulationIndustrial premisesIndustrial Factory

The invention provides a repair method for existing industrial factory building production equipment, the production equipment comprises a plurality of components and a base, the repairing method comprises the following steps: carrying out three-dimensional scanning on the production equipment to form a model diagram, and determining defective failure components in the production equipment according to the model diagram; reinforcing the base, supporting and reinforcing the position, corresponding to the failure component, of the production equipment and removing the failure component; repairing the part, corresponding to the failure component, in the model diagram, making a replacement component corresponding to the failure component according to the repaired model diagram, and installing the replacement component correspondingly on production equipment; and carrying out antique repair treatment on the surface of the production equipment. To-be-repaired parts of the existing production equipment is subjected to cleaning, component replacement, reinforcement and distressing treatment, and the factory building is repaired under the condition that the original production equipment is reserved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

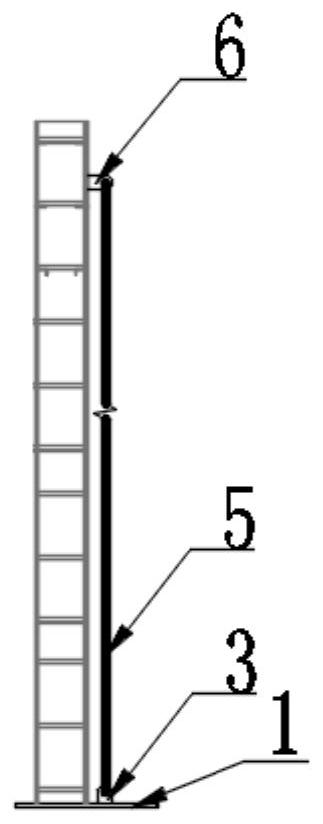

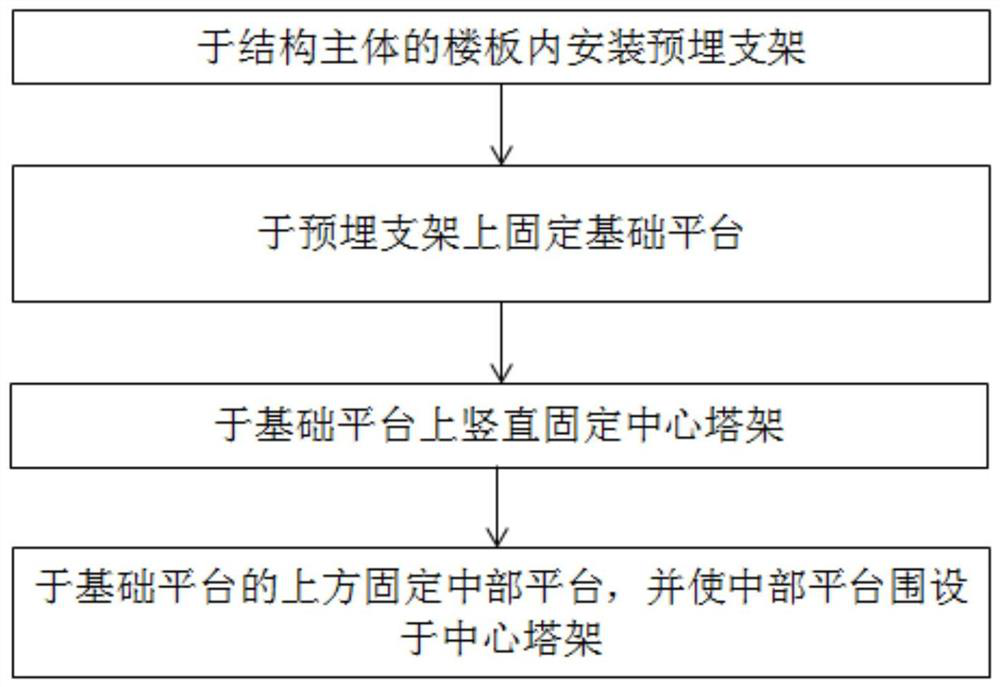

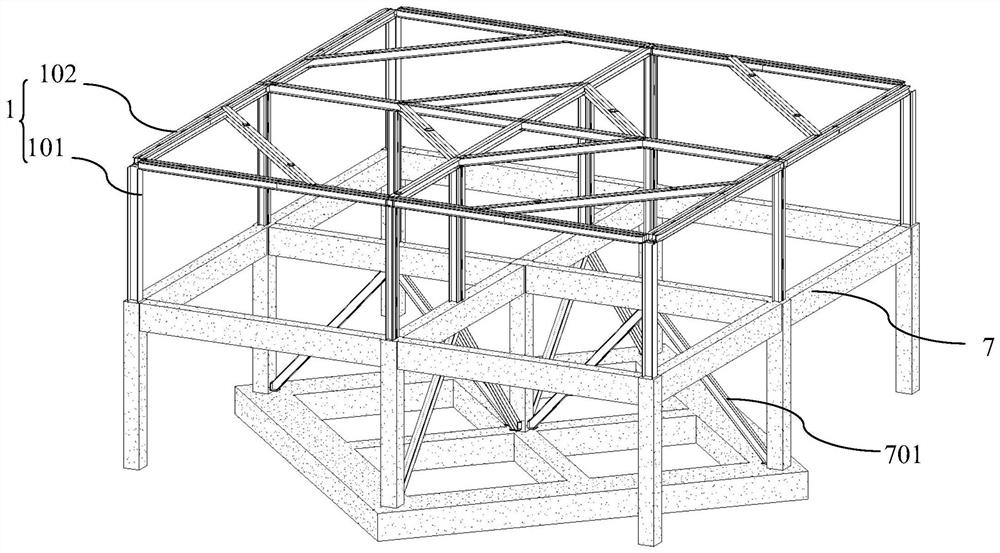

Construction method of high-altitude supporting operation frame based on bottom steel platform

ActiveCN113323361ATroubleshoot unmanageable technical issuesGuaranteed verticalityWind energy generationScaffold accessoriesFloor slabArchitectural engineering

The invention discloses a construction method of a high-altitude supporting operation frame based on a bottom steel platform. The construction method comprises the following steps that an embedded support is installed in a floor slab of a structure body; a foundation platform is fixed to the embedded support; a central tower is vertically fixed on the foundation platform; and a middle platform is fixed above the foundation platform, and the middle platform is arranged on the central tower in a surrounding manner. By means of the construction method, the technical problem that in the prior art, the perpendicularity is difficult to control when a high-altitude supporting operation frame system is erected is solved in the manner that the middle platform and a reinforcing platform are arranged around the center tower in the surrounding manner. According to the construction method, it can be guaranteed that errors of the perpendicularity and the plane elevation of the high-altitude supporting operation frame meet the requirements, and therefore it is guaranteed that the installation precision of an indoor special-shaped metal structure building meets the requirements; and the embedded support is collected to the structural floor slab, supporting structures are arranged below key stress points of the floor slab, and therefore a whole frame body is stable and safe. The construction method is simple and convenient, and construction cost investment can be greatly reduced.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A brick joint filling and pointing device and construction method

The invention discloses a brick joint filling and pointing device and a construction method. The device includes a joint filling and pointing trolley capable of moving back and forth on the surface of a masonry structure and a storage hopper for storing mortar filled in brick joints , there is a butt joint at the bottom of the storage hopper; the caulking and pointing trolley includes a frame, a slurry feeding channel, a connecting joint, a walking mechanism and a pointing device. There are two mortar extrusion bars on the outside of the frame, and the pointing device includes Two pointing mechanisms, the pointing mechanism includes a connecting frame and a groove wheel; the construction method is to use a brick joint filling and jointing device to fill or joint the processed brick joints. The invention is reasonably designed, easy to use, and has high construction efficiency and good use effect. The movable brick joint filling and pointing device is used to fill or point out the brick joints, and the filling mortar can be automatically sent into the processed brick joints. , and can compact and groove the filling mortar sent into the brick joints, and can ensure the quality of joint filling and pointing.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

Combinable telescopic sleeve jacking device and method thereof

ActiveCN111058618BImprove structural construction efficiencyImprove construction efficiencyForms/shuttering/falseworksBraced frameArchitectural engineering

The invention belongs to the technical field of construction engineering, and in particular relates to a combinable telescopic sleeve jacking device and a method thereof. There are a series of problems such as a large number of transmission mechanisms, poor adaptability to the narrow cylinder space, and low flexibility in combined construction. It includes a number of jacking unit modules, a horizontal jacking frame, an upper support frame, a lower support frame and several longitudinal connecting beams. The unit jacking module includes a jacking cylinder and a telescopic sleeve frame; the jacking cylinder is set at the center of the telescopic sleeve frame , the upper end is connected with the horizontal jacking frame, the jacking cylinder passes through the gap between the longitudinal connecting beams of the upper supporting frame, and its lower end is connected with the lower supporting frame; by providing a single cylinder jacking module with a telescopic sleeve frame The device can independently carry out the jacking operation of the formwork system, and can also carry out multi-module combined jacking according to the construction needs of large-space cylinders to realize large-load three-dimensional operations.

Owner:SHANGHAI CONSTRUCTION GROUP

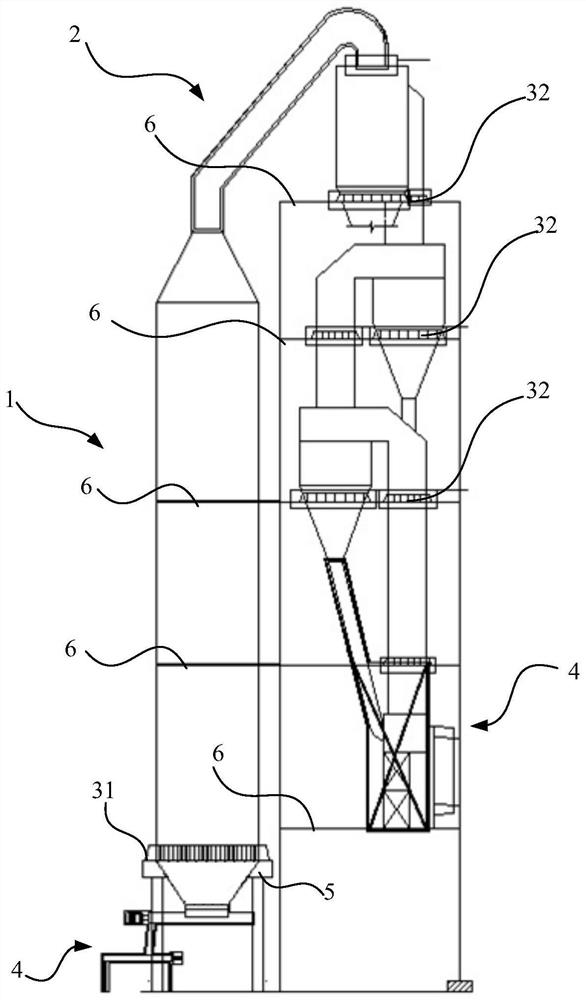

A transport device and transport method for coke oven refractories

ActiveCN104355077BImprove transportation construction progressShorten the construction periodMechanical conveyorsRefractoryCoke oven

Owner:CHINA MCC17 GRP

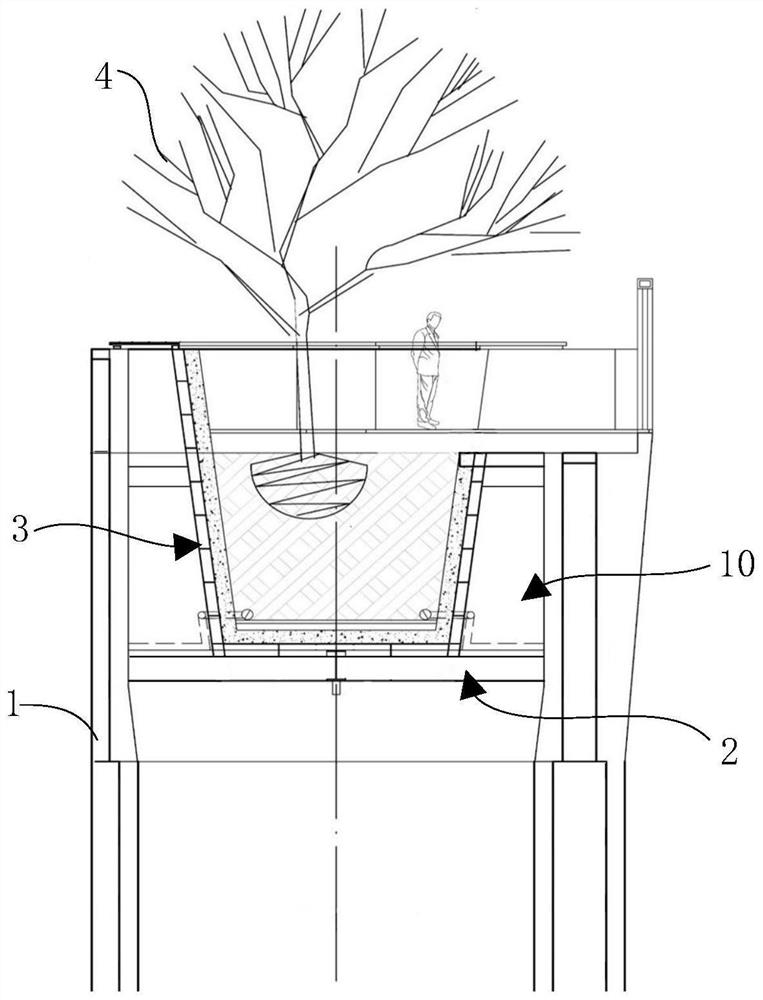

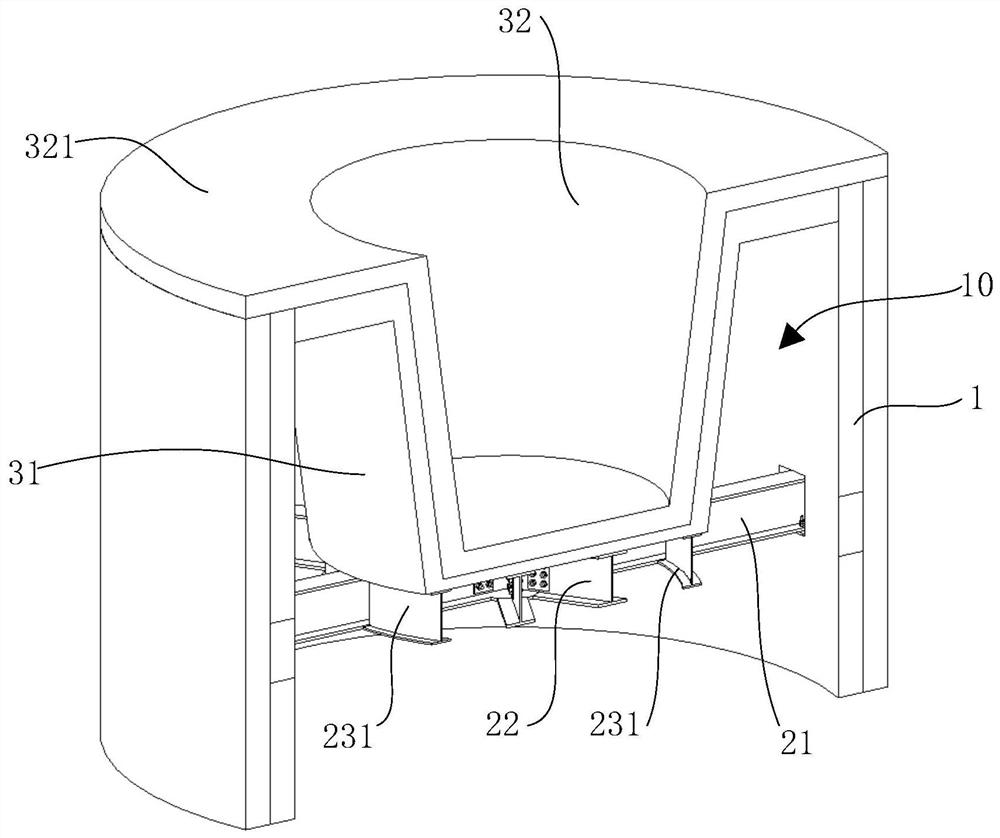

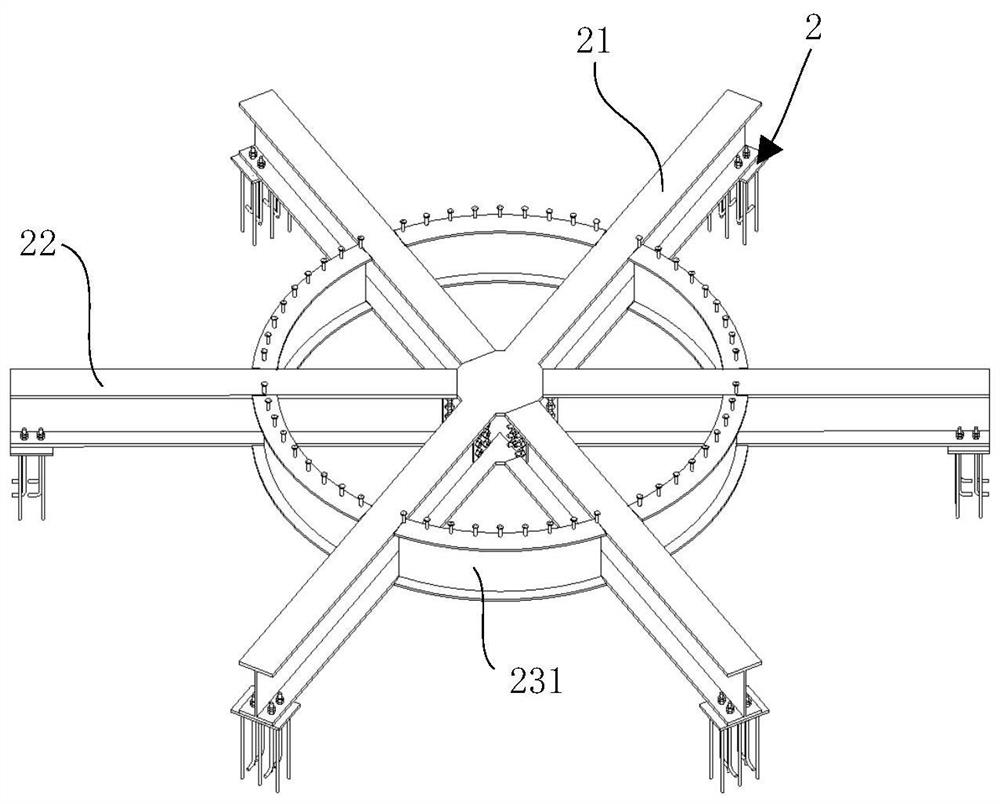

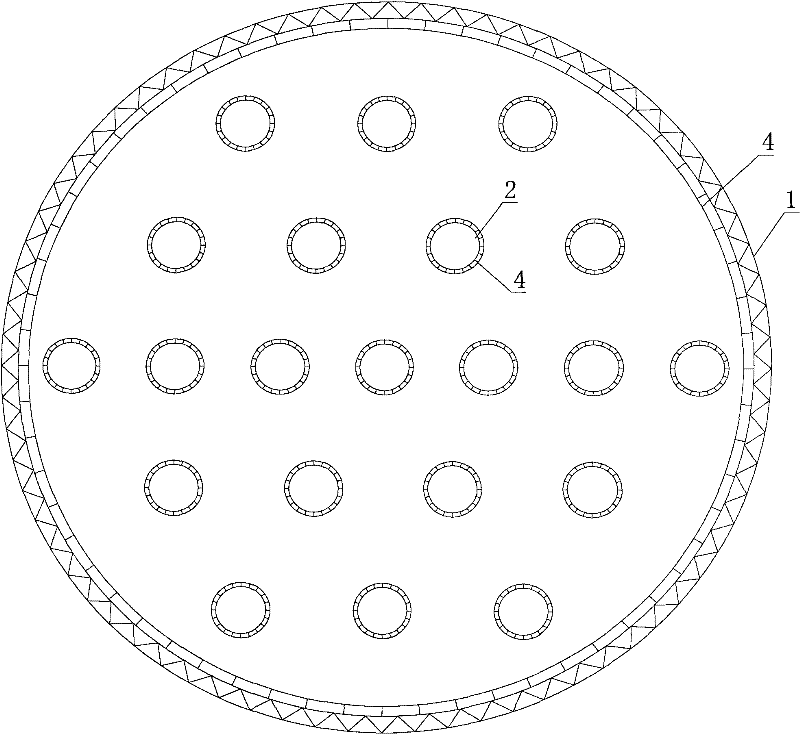

Silo structure three-dimensional greening structure and construction method thereof

PendingCN113668780AFlexible locationEnsure safetyBuilding roofsRoof coveringAgricultural engineeringGreening

The invention discloses a silo structure three-dimensional greening structure and a construction method thereof. The silo structure three-dimensional greening structure comprises a main body structure, a bearing frame and a planting pool, and a vertically arranged cylindrical cavity is formed in the upper part of the main body structure; the bearing frame comprises a bearing beam, a plurality of supporting beams and a ring beam, the two ends of the bearing beam are correspondingly installed on the two opposite side walls of the cylindrical cavity, the multiple supporting beams are connected between the two opposite sides of the bearing beam and the side walls of the cylindrical cavity, the supporting beams are arranged in the radial direction of the cylindrical cavity, the ring beam and the cylindrical cavity are coaxially arranged, the ring beam and the cylindrical cavity are coaxially arranged, and the ring beam is connected to the bearing beam and the multiple supporting beams; and the planting pool is used for planting large arbors and is contained in the cylindrical cavity, the bearing frame is supported at the bottom of the planting pool, a plurality of positioning beams are connected between a pool opening of the planting pool and an upper end opening of the cylindrical cavity, and the positioning beams are arranged in the circumferential direction of the pool opening at intervals. The problem that the greening planting form and planting position of a traditional building structure are single is solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

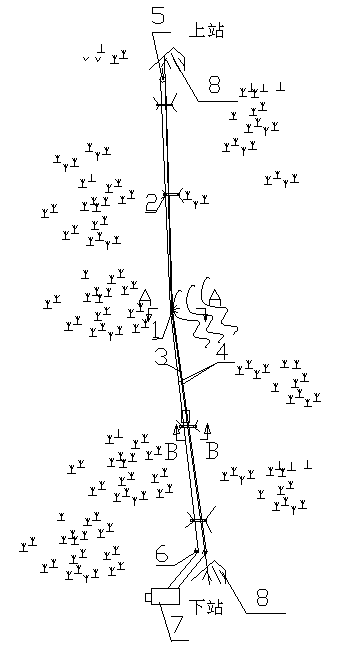

Quick-transporting method and quick-transport device for foldable temporary cableways

ActiveCN102602398BReduce the number of settingsImprove transportation efficiencyRope railwaysRailway track constructionEngineeringWinch

The invention discloses a quick-transport device for foldable temporary cableways, which consists of an independent-rod temporary cableway bracket, a door-shaped temporary cableway bracket, a bearing cable, traction cables, a return sheave, a guide sheave, a traction driving grinding winch, a bearing cable anchoring pier, transporting running carts, chain blocks and a cargo shelf (15). A quick-transport method for the foldable temporary cableways includes: firstly, selecting temporary cableway transporting lines and erecting temporary cableways; secondly, setting the transporting running carts and the cargo shelf; and thirdly transporting equipment materials. By the quick-transport device and the quick-transport method which are convenient and reliable, difficulty in transporting of equipment and materials on steep mountains is reduced, the number of the temporary cableways is reduced, and transporting efficiency of the temporary cableways is improved.

Owner:CHINA MCC17 GRP

The construction method of sprayed concrete for the mobile formwork of the inner mold of the airbag and the initial support of the tunnel

The invention discloses a mobile formwork for an airbag inner mold and a construction method for sprayed concrete for initial support of a tunnel. Telescopic support device, the telescopic support device is installed on the mobile support bent frame and it is located inside the inflatable formwork; the construction method includes steps: 1. The mobile formwork of the inner mold of the airbag is moved forward to the position; 2. The initial support of the tunnel is shotcrete Construction; 3. Sprayed concrete construction for the initial support of the next tunnel segment; 4. Repeat step 3 several times until the construction process of the sprayed concrete for the initial support of all tunnel segments is completed. The invention is reasonable in design, simple in construction and good in use effect. The rebound rate of shotcrete for initial support of tunnels is effectively controlled through the inner mold of the airbag, and the construction efficiency is high, the construction period is short and the construction quality is high, and the spraying of initial support of tunnels can be realized. Concrete has zero rebound.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

A Construction Method of Triaxial Mixing Pile in High Local Strength Stratum

ActiveCN110185028BReduce earth excavationReduced perfusionBulkheads/pilesReinforced concreteEarth surface

The invention relates to a construction method of a three-axis stirring pile in a stratum with relatively high local strength. The steps are: construction preparation → measurement and lofting → trench excavation → empty stirring to determine the processing range → rotary digging and backfilling sand → three-axis stirring pile Construction→grouting reinforcement→acceptance. In the present invention, the specific construction range affecting the three-axis mixing pile is determined by consulting the drawings and on-site survey, combined with the three-axis mixing drilling rig, and then using the rotary drilling rig to dig out the soil that affects the construction of the three-axis mixing pile and using machine-made sand Backfill the borehole, then carry out the construction of the three-axis mixing pile, and finally carry out surface grouting reinforcement on both sides of the three-axis mixing pile, which can effectively improve the construction efficiency, ensure the smooth progress of the construction, and ensure the construction quality. The input of materials such as concrete and concrete can reduce dust pollution in the process of earthwork excavation, storage, and transportation, and has a small impact on the environment.

Owner:中建三局城建有限公司 +1

Method for salvaging large bottom supporting plate integrally descending into river in blocking mode

ActiveCN111021360AGoing down the river is safe and smoothReduce demandFoundation engineeringBridge erection/assemblyMarine engineeringUnderwater

The invention discloses a method for salvaging a large bottom supporting plate integrally descending into the river in a blocking mode. The large bottom supporting plate is partitioned; all the blocksare spliced together through the connecting structures and then connected with the large steel structure into a whole, stable self-floating of the large steel structure is achieved after the large steel structure enters water, connection with the large steel structure is cut off, the splicing structures between all the blocks are snapped through the self-weight of the large bottom supporting plate, and the large bottom supporting plate is automatically blocked and salvaged underwater. According to the method, large salvage equipment and diver operation are not needed, rapid recycling and cyclic utilization are achieved, high safety and economical efficiency are achieved, labor investment and working hours are reduced, construction cost investment is effectively reduced and the construction period is shortened.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

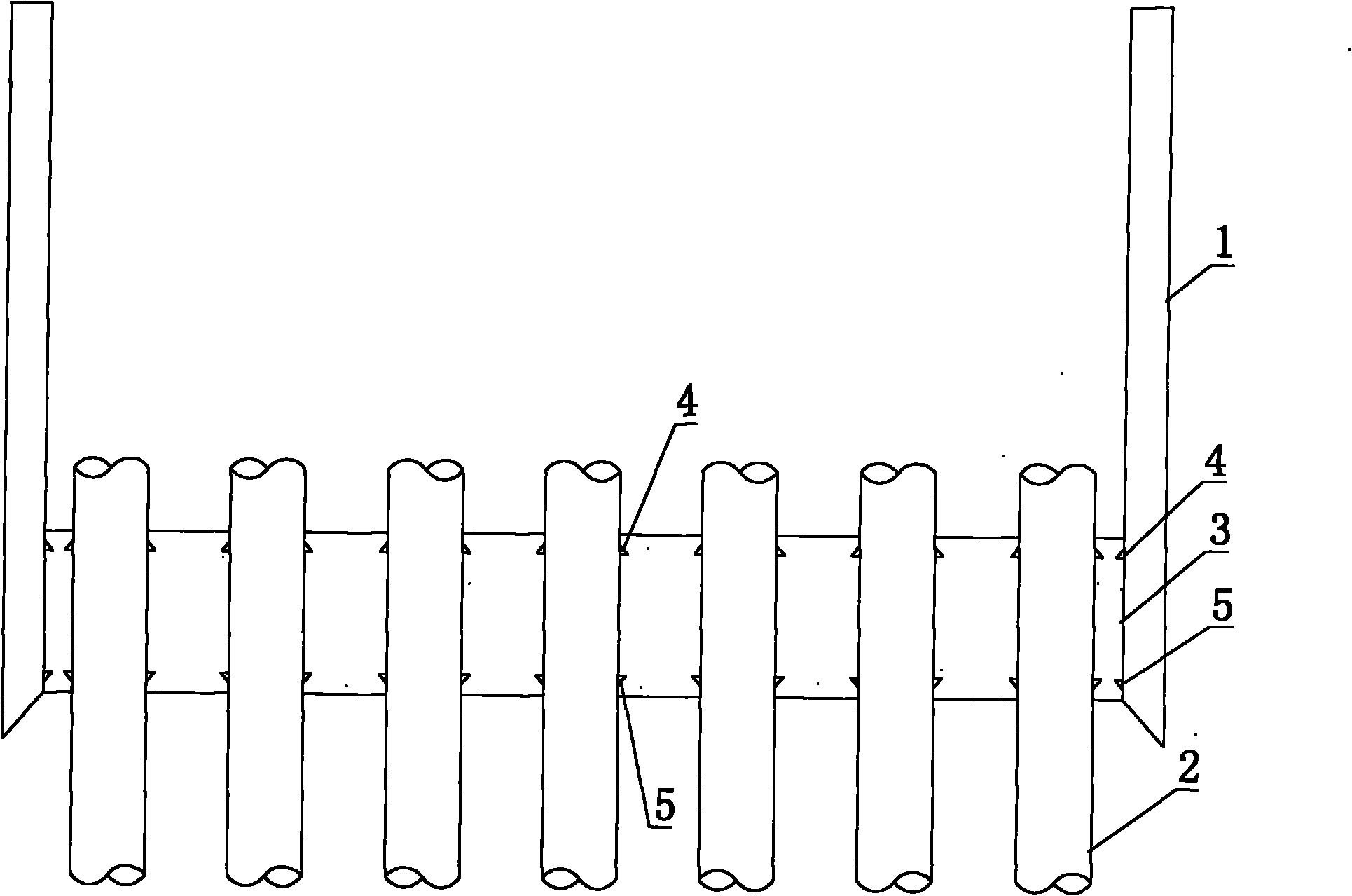

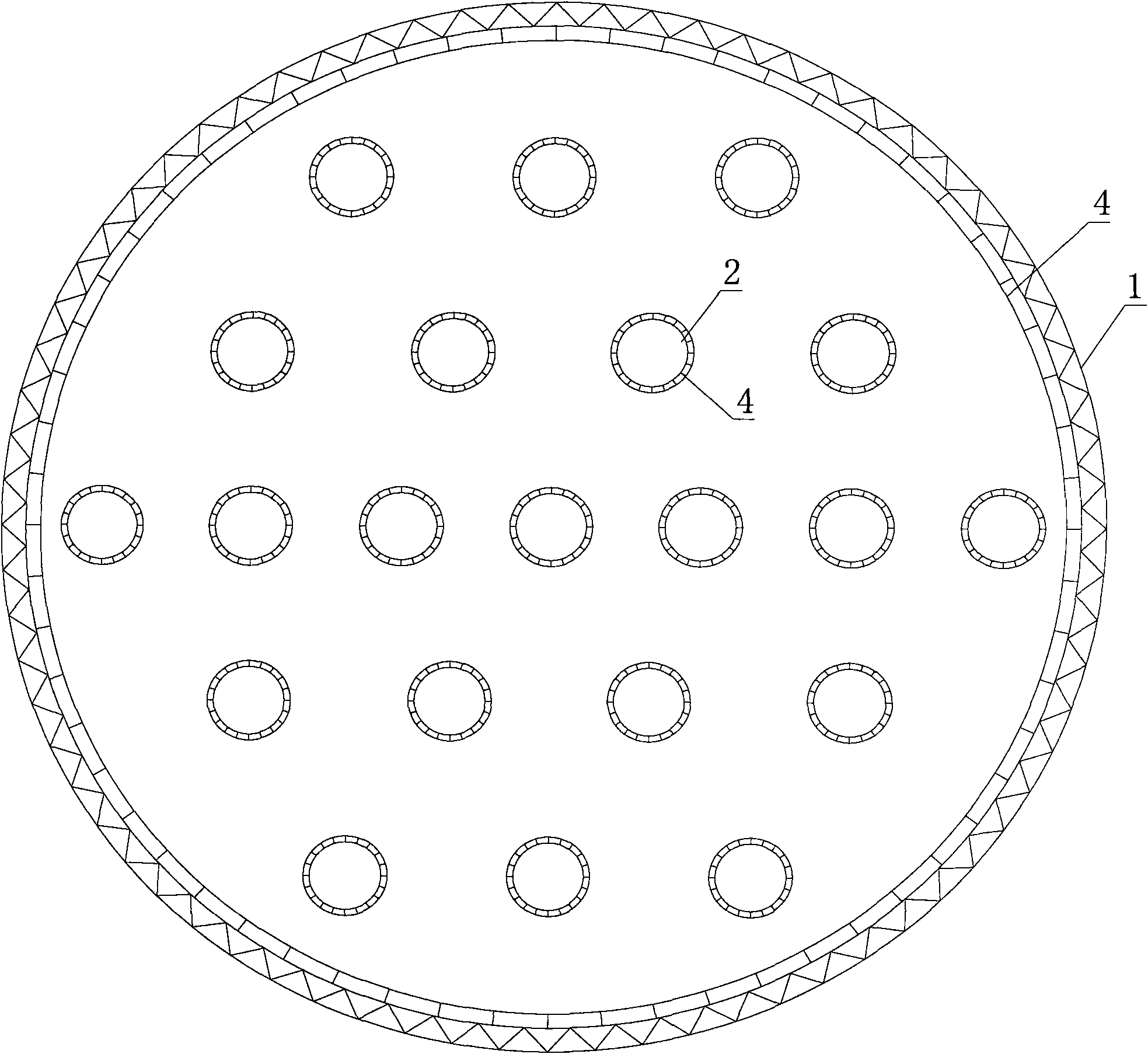

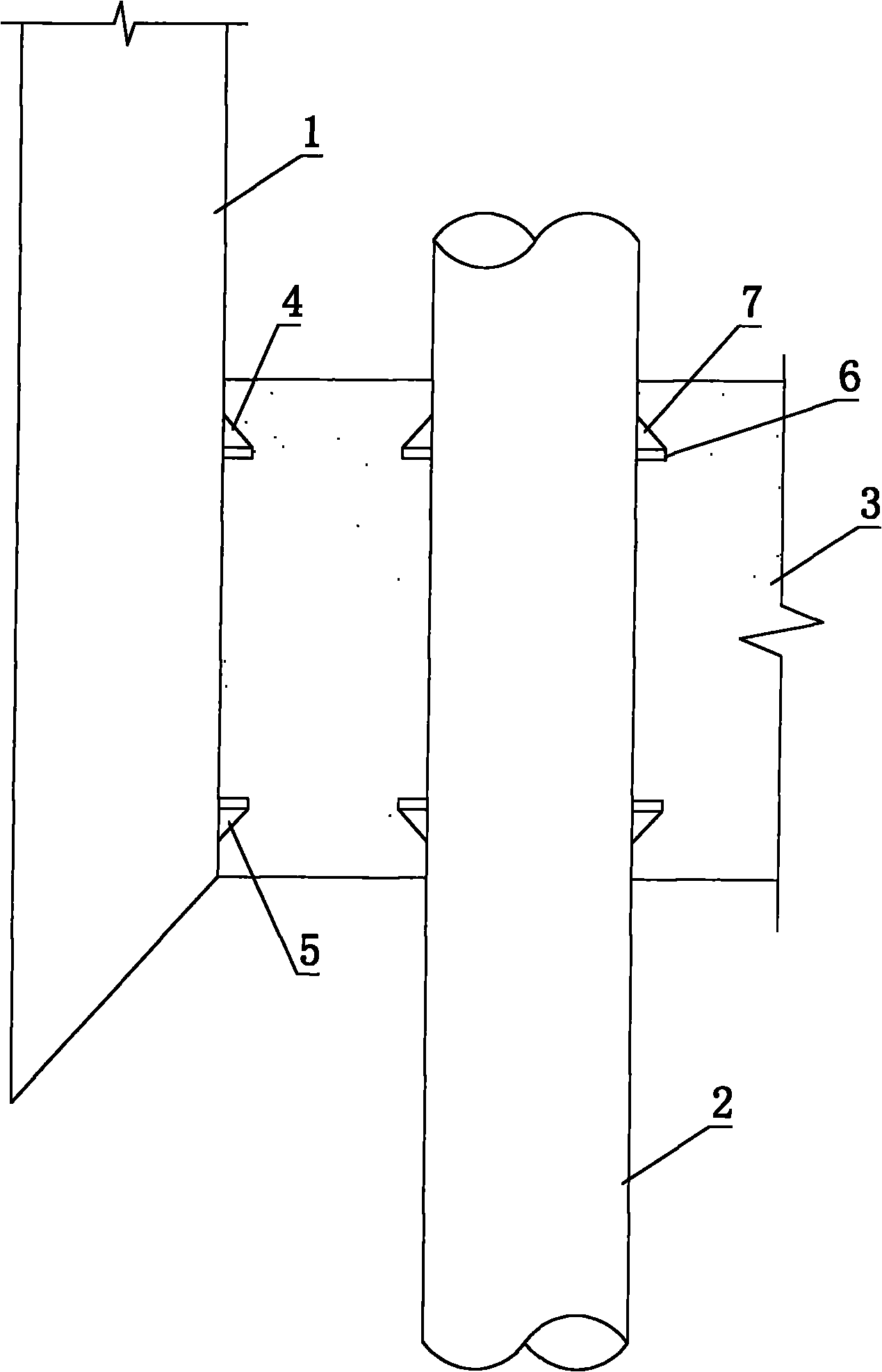

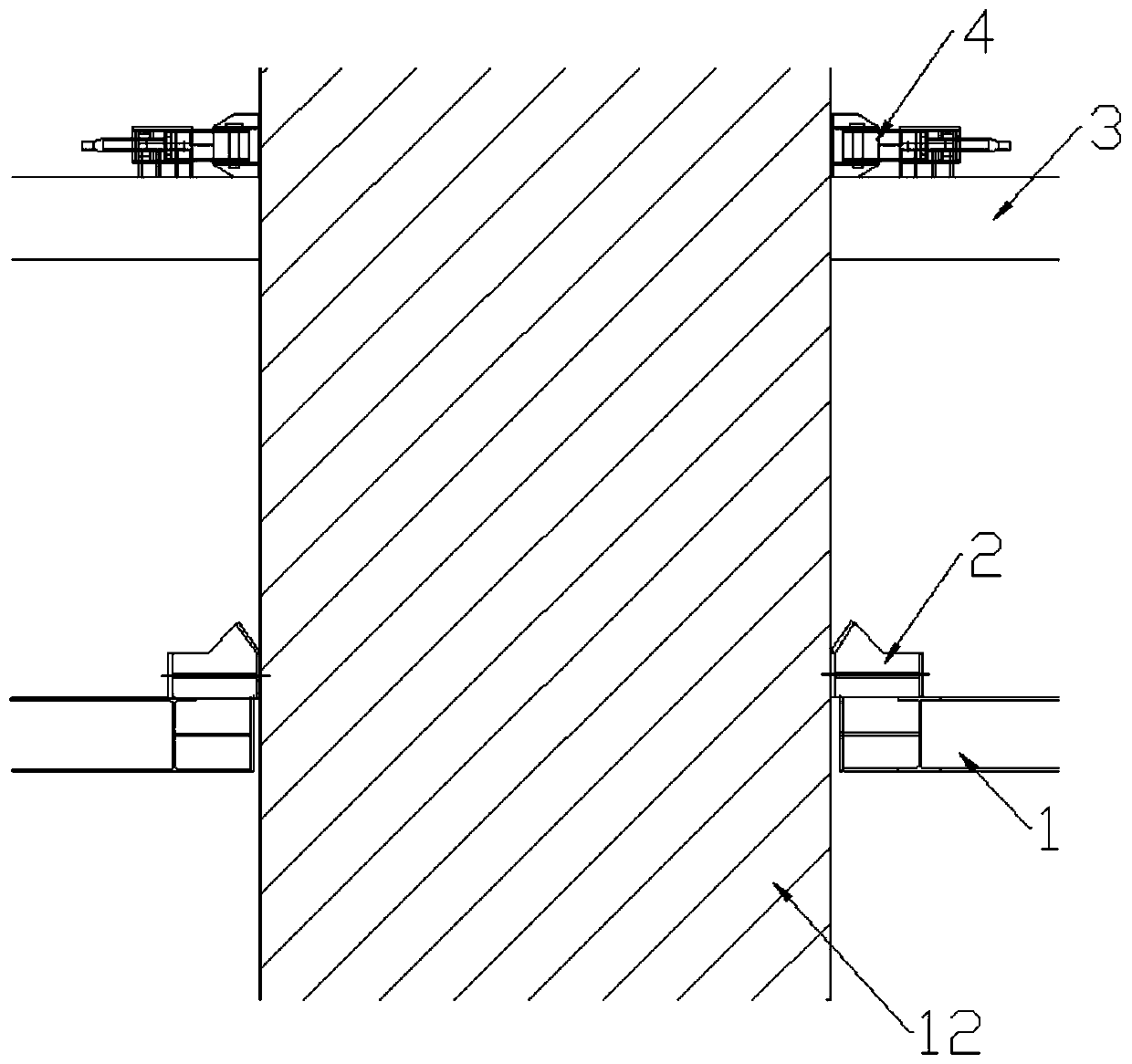

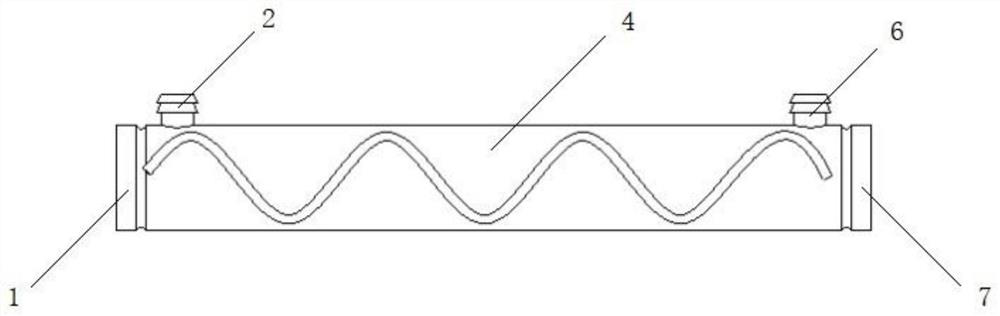

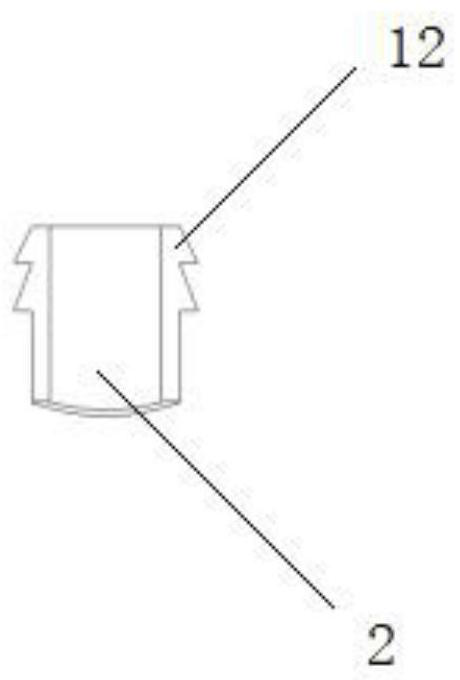

Grout sleeve for steel bar connection and machining process of grout sleeve

PendingCN111734052ASmooth dischargeImprove uniformityBuilding reinforcementsSteel barMachining process

The invention relates to the technical field of steel bar sleeve grouting and discloses a grout sleeve for steel bar connection. The grout sleeve comprises an on-site assembling end and a prefabricated mounting end which are sequentially arranged in the grout flowing direction, wherein the on-site assembling end is provided with a feeding through hole, and the prefabricated mounting end is provided with a discharging through hole; a feeding conduit is fixed to the feeding through hole, and a discharging conduit is fixed to the discharging through hole; two wavy bosses are arranged on the innerwall of a grout sleeve body and are distributed at the two sides of a longitudinal section of the grout sleeve body in spatial symmetry along a longitudinal line; and upper groove lines are arrangedabove a transverse section of the outer wall of the grout sleeve body, lower groove lines are arranged below the transverse section of the outer wall of the grout sleeve body, and heat exchange circulating pipelines are tightly attached to the upper groove lines and the lower groove lines respectively. According to the grout sleeve, bubbles introduced in the grout construction process can be smoothly discharged, the universality of stress of a grout connecting joint of the steel bar sleeve is improved, the machining difficulty of the grout sleeve is lowered, the process is simple, the universality is high, and the requirement for construction in winter and summer can be met.

Owner:武汉合创炬盛科技有限公司

Method for reducing thickness of subsealing concrete of steel cofferdam and preventing seepage

ActiveCN102094428BPlay the role of water stopImprove carrying capacityFoundation engineeringTransfer modeCofferdam

The invention discloses a method for reducing the thickness of subsealing concrete of a steel cofferdam and preventing seepage, comprising the following steps of: a. assembling the steel cofferdam and welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure along the inner wall of the steel cofferdam; b. feeding the steel cofferdam in water; c. welding an upper circle of shearing resistant structure and a lower circle of shearing resistant structure on the outer wall of each steel protecting tube and sequentially punching the steel protecting tubes into a foundation in the steel cofferdam; d. constructing all drilling piles; e. cleaning the foundation in the steel cofferdam and flushing the steel cofferdam and the shearing resistant structures underwater on the steel protecting tubes; f. pouring the subsealing concrete to be combined with the steel protecting tubes, the steel cofferdam and the shearing resistant structure into a whole;and g. pumping water from the steel cofferdam and constructing a bearing platform. According to the method, by arranging the shearing resistant structures, after water in the steel cofferdam is pumped, the force transfer mode of the subsealing concrete and the inner wall of the steel cofferdam and the outer walls of the steel protecting tubes is converted into a bonding force and a shearing forcefrom the mutual bonding force, so that the dereference of the concrete bearing capacity accords with the reliable basis and the thickness of the subsealing concrete can be reduced; and the water seepagae in the steel cofferdam can be prevented.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

Arc-shaped line construction formwork structure

PendingCN111794495AOverall stabilityGood molding effect at one timeForms/shuttering/falseworksForming/stuttering elementsPolishingBoard structure

The invention provides an arc-shaped line construction formwork structure, and belongs to the technical field of building construction. The arc-shaped line construction template structure comprises asemi-arc-shaped steel formwork, a female corner C-shaped aluminum formwork and a beam side U-shaped aluminum formwork which are sequentially butted from top to bottom, pin holes are distributed in thefemale corner C-shaped aluminum formwork and the beam side U-shaped aluminum formwork, pins used for fixing the formworks on the outer side of a cast-in-place balcony are correspondingly arranged inthe pin holes, the semi-circular arc-shaped steel formwork comprises a shaping steel plate and a connecting plate transversely connected and fixed to the lower side of the shaping steel plate, the shaping steel plate is transversely arranged and a vertical section is a semi-circular arc, the lower side of the connecting plate is fixedly attached to the upper part of the internal corner C-shaped aluminum formwork, and the inner side of the cambered surface of the shaping steel plate is matched with the designed cambered surface of the outer side of the cast-in-place balcony. The structure solves the problems that an existing method is poor in forming effect, the turnover frequency of a wood formwork or a plastic formwork is small, the forming quality cannot be guaranteed, a plurality of later repairing and polishing processes exist, the construction progress is not improved, and the construction investment cost is increased.

Owner:CHINA CONSTR FOURTH ENG DIV +1

Rainwater recovery system and construction method for sponge city overpass

ActiveCN106758799BRelieve water stressGuaranteed trafficFatty/oily/floating substances removal devicesSewerage structuresWater storageRainwater harvesting

The invention discloses a rainwater recycling system for sponge city overpass and a construction method of the rainwater recycling system. The rainwater recycling system comprises a rainwater collection device, rainwater pretreatment equipment and a water storage well, the rainwater collection device comprises a rainwater pipe and a collector, a water collection pump is mounted on the collector, and the rear end of the rainwater pipe is connected onto the water collection pump while the front end of the same is connected onto a deck of the overpass; the lower end of the collector is connected with a first guide pipe, the other end of the first guide pipe is connected with the rainwater pretreatment equipment, a diverter is mounted at the lower end of the rainwater pretreatment equipment, a second guide pipe is connected on the diverter and connected to the water storage well, a submerged pump is mounted in the water storage well, and a recycling pipe is connected on the submerged pump. An existing overpass draining pipeline is introduced into the collector, and rainwater is purified with the help of the rainwater pretreatment equipment, guided into the water storage well and then recycled through the recycling pipe, so that reasonable utilization of rainwater resources is realized, city water consumption pressure is relieved, the draining problem of the overpass is solved effectively, and city traffic is guaranteed.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

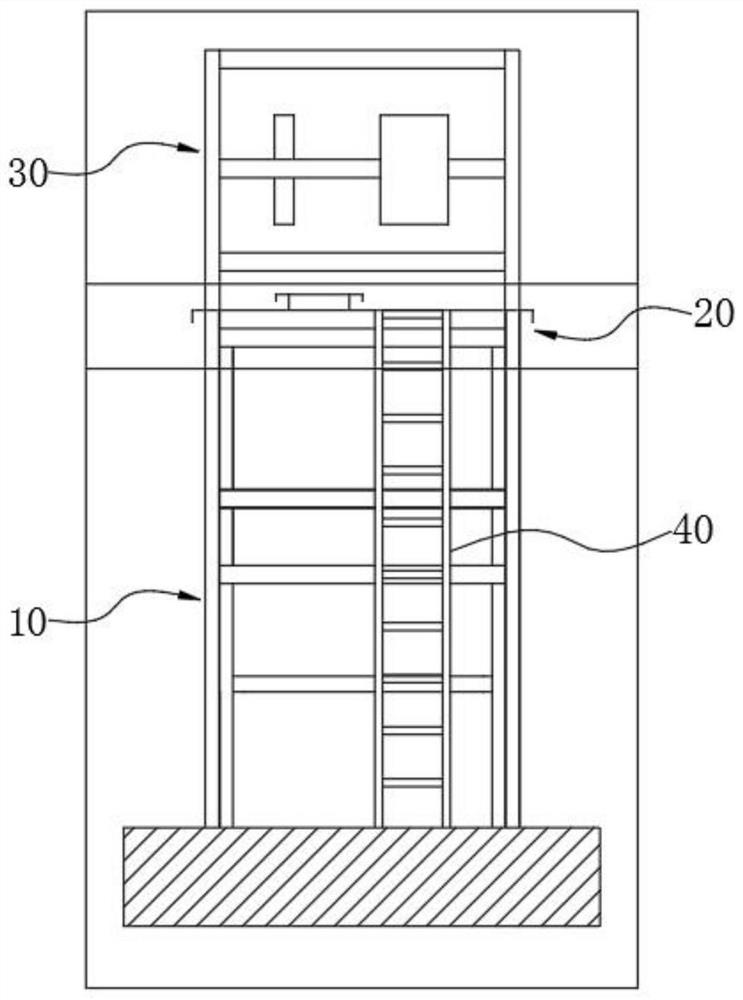

Elevator hoistway frame and elevator

PendingCN112499422AImprove signal shielding effectTake advantage ofElevatorsBuilding liftsIsolation layerTower

The invention relates to an elevator hoistway frame and an elevator. The elevator hoistway frame comprises a hoistway frame body, an isolation layer frame and a communication base station frame, wherein the isolation layer frame is arranged at the top of the hoistway frame body; the communication base station frame is arranged on the isolation layer frame; and the communication base station frameand the hoistway frame body are arranged on the two opposite sides of the isolation layer frame respectively. According to the scheme, the communication base station frame is integrated above the hoistway frame body, so that the top space of the hoistway frame is fully utilized, meanwhile, the communication base station frame is prevented from additionally and independently occupying a public space, the construction investment of a signal tower is reduced and avoided, and the early-stage construction cost investment is greatly reduced; and in addition, the isolation layer frame located in themiddle plays a good role in signal shielding, so that all the elevator function assemblies installed on the hoistway frame body and all the communication base station devices installed on the communication base station frame operate independently and normally and do not interfere with one another.

Owner:HITACHI ELEVATOR CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com