Water recession system adopting steel-structure derrick-type water recession opening and construction method thereof

A steel structure and derrick technology, applied in the field of water retreat system, can solve problems such as poor flatness of the dredging reclamation area, seepage and collapse of the weir body, adverse social impact, etc., and achieve small safety risks, easy safety management, and reduced construction cost investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing, the present invention is described in further detail:

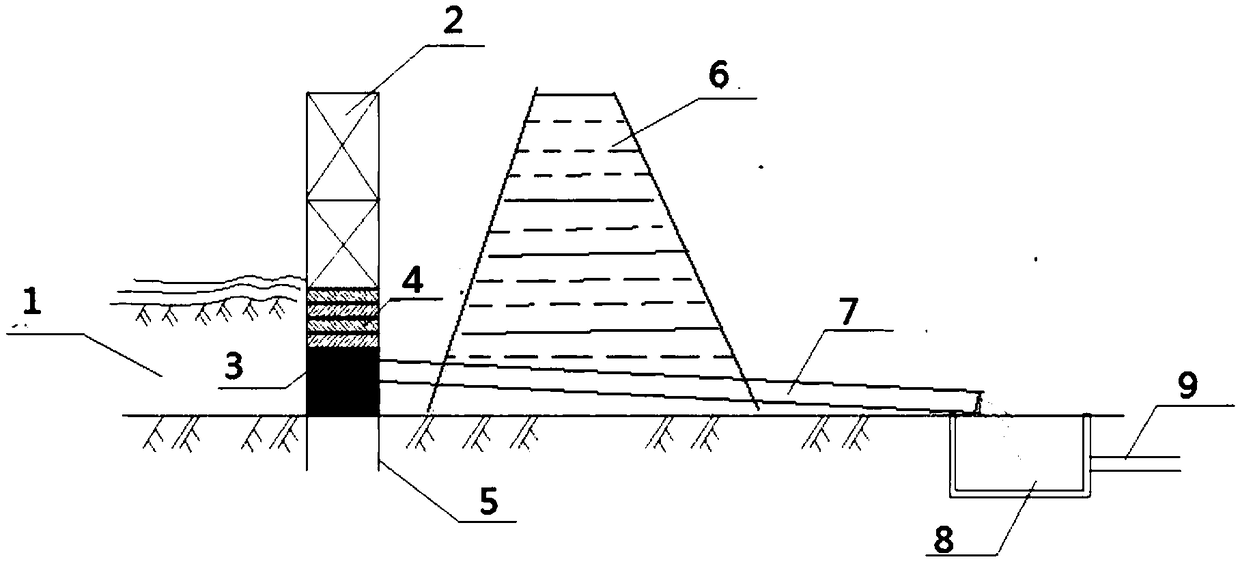

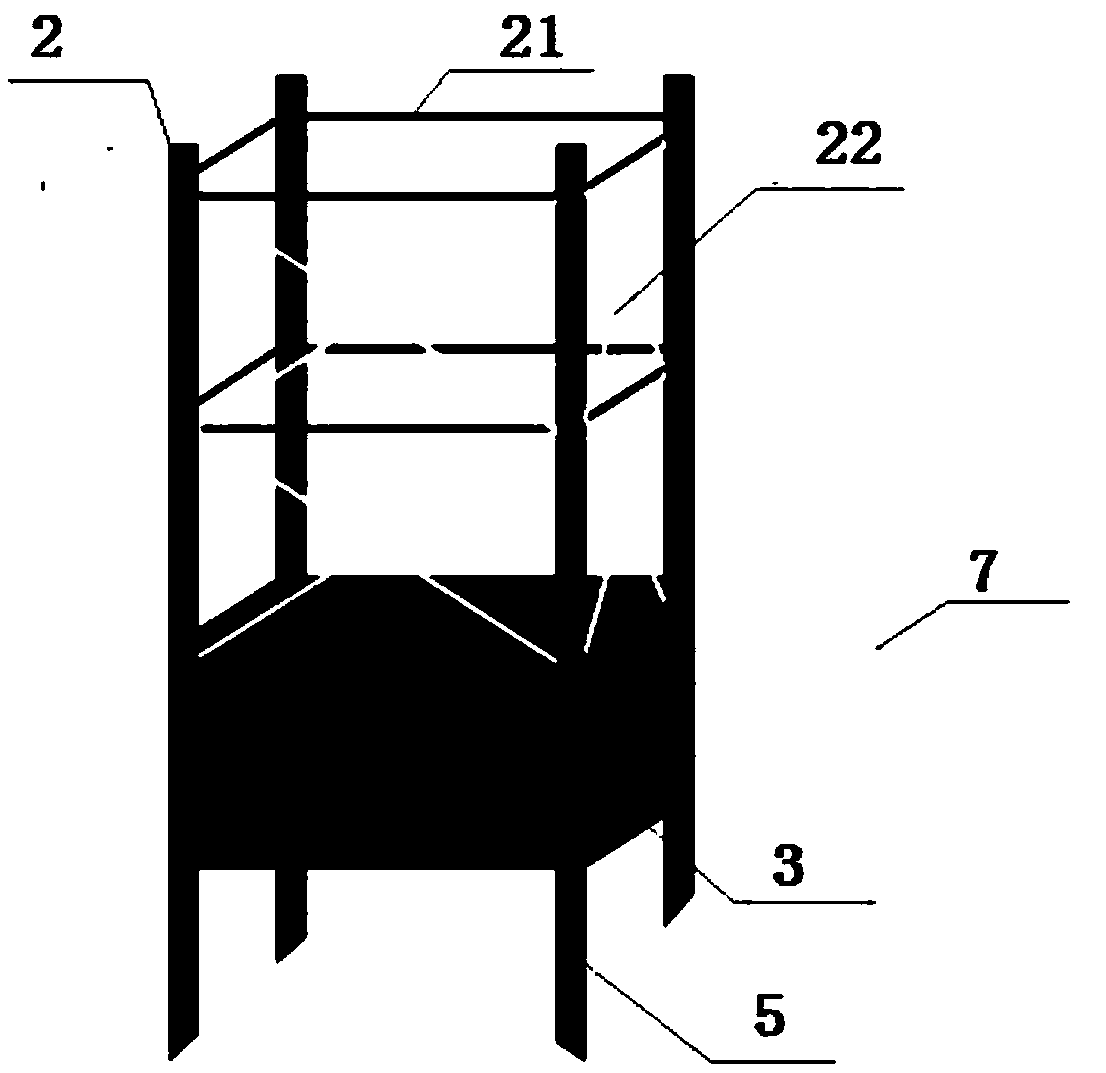

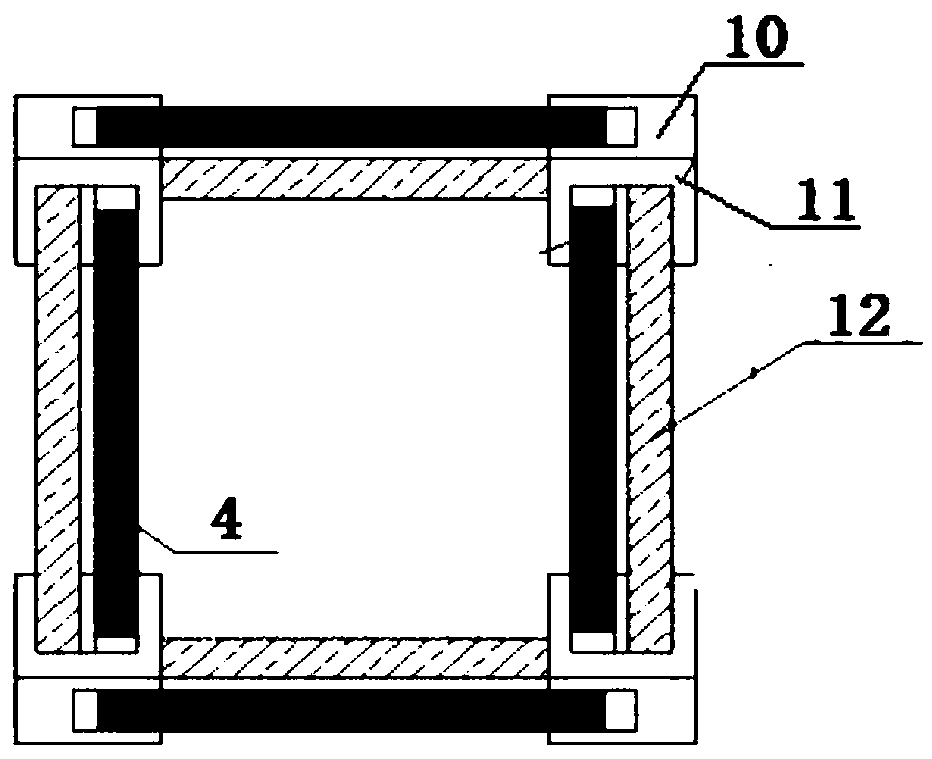

[0022] A water receding system adopting a steel structure derrick type water receding outlet of the present invention mainly includes a channel steel frame 2, a fender 4, a water receding pipe 7, an energy dissipation pool 8, and a water receding channel 9, and the channel steel frame 2 is composed of The channel steel is fixed by the horizontal support 21 and the scissors support 22 to form a column frame, and a water tank 3 is arranged on the channel steel frame 2, and a 1m channel steel 5 is left under the bottom of the water tank 3, and the fender 4 is set In the channel steel channel of the channel steel frame 2 above the water tank 3, one end of the water withdrawal pipe 7 is inserted into the opening, and the other end of the water withdrawal pipe 7 passes through the cofferdam 6 and extends into the energy dissipation pool 8. A drain 9 is provided on the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com