A Construction Method of Triaxial Mixing Pile in High Local Strength Stratum

A construction method and technology for mixing piles, which are applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of construction progress and construction quality, sudden changes in geological conditions, difficult drilling, etc. Small impact and good pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0039] A method for constructing a three-axis mixing pile in a stratum with relatively high local strength, comprising the following steps:

[0040] Step 1: Construction preparation

[0041] Before construction, level and tamp the site, introduce measurement and control network; carefully collect geological data, study and analyze geological survey reports and design drawings, analyze and count the stratum range that may affect the normal construction of triaxial mixing piles; conduct process tests to determine the triaxial mixing piles 1 Construction control parameters.

[0042] Step 2: Measurement and Stakeout

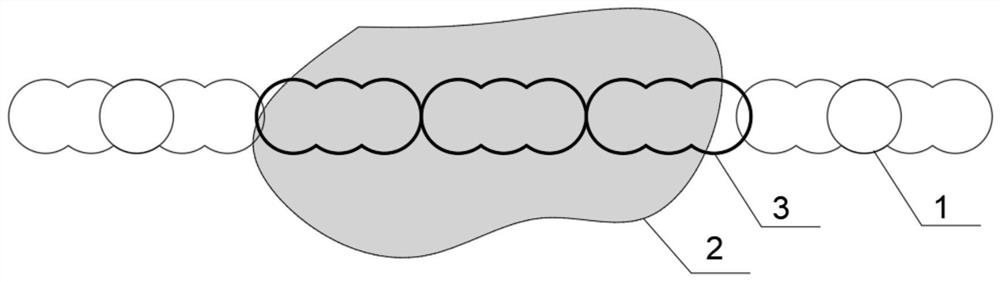

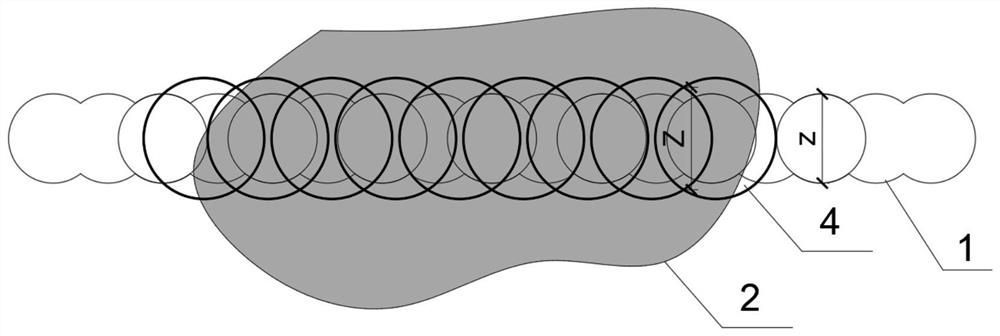

[0043] According to the design drawings, the position of the three-axis mixing pile 1 is set out, and the position of the stratum range 2 that may affect the normal construction of the three-axis mixing pile is marked.

[0044] Step 3: Trench Exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com