Pipe reinforcement connection device for sewer system

A technology for connecting devices and sewers, which is applied in the directions of pipe supports, sleeve/socket connections, pipes/pipe joints/pipes, etc. It can solve the problems of inability to install, seal and disassemble pipes, and achieve the effect of reducing excavation works and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

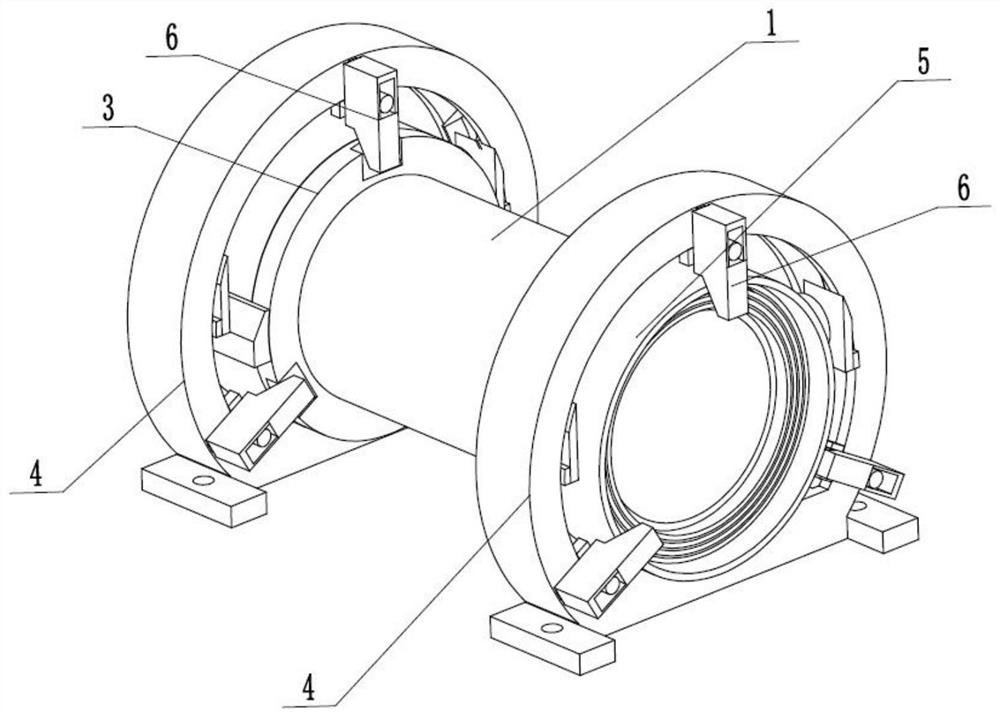

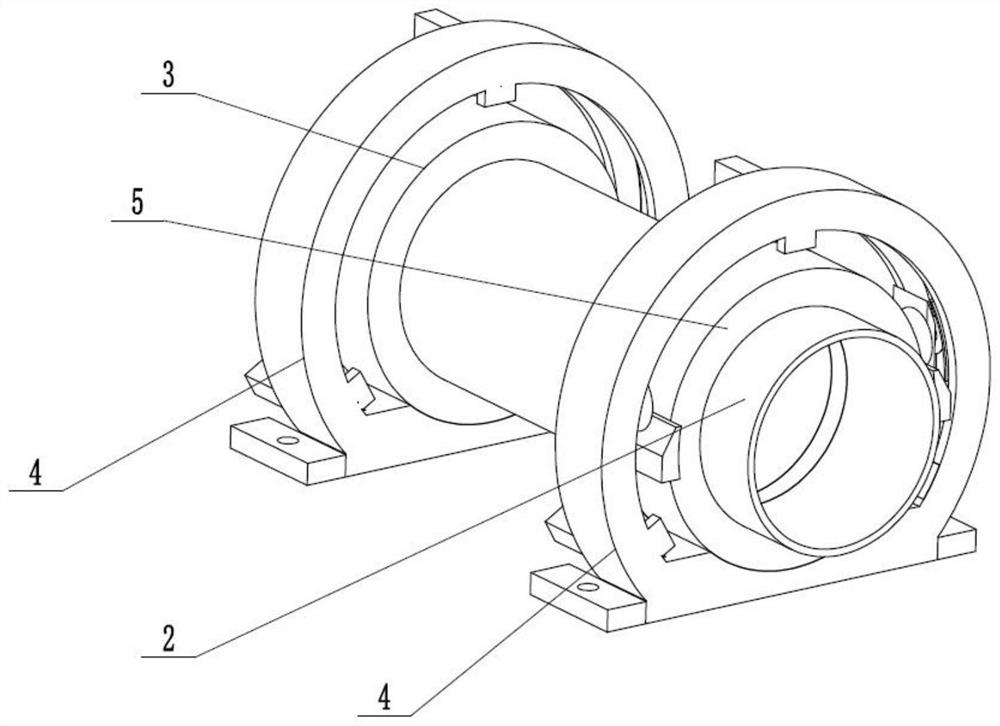

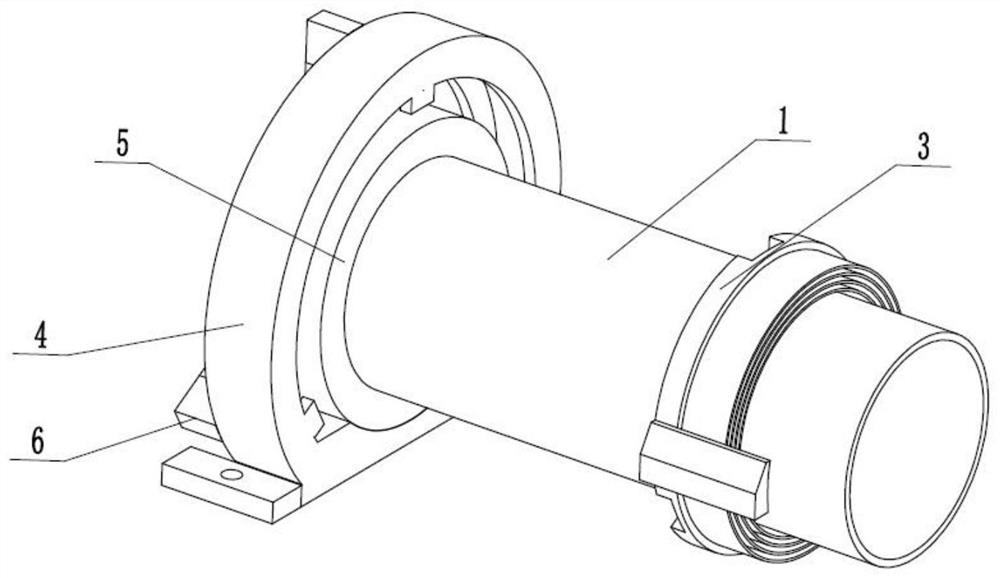

[0031] like Figure 1 to Figure 12As shown, a pipe reinforcement connection device for a sewer system, including a joint pipe 1, a fixed pipe 2, a joint seal socket 3, a fixed support seal base 4, a fixed seal socket 5 and an adjustment locking fixture 6, the described The joint seal socket 3 is fixedly connected to the inner end of the joint pipe 1, the joint seal socket 3 is plugged and sealed in the fixed support seal base 4, the fixed support seal base 4 is fixedly connected to the outer end of the fixed connection fixed pipe 2, and the fixed support seal base 4 is fixedly connected to the fixed sealing socket 5, and the adjusting locking fixer 6 is slidably connected in the fixed sealing socket 5, and the adjusting locking fixing device 6 is meshed with the joint sealing socket 3 for transmission, and the adjusting locking fixing device 6 is closely fitted to the plug Connected in the connecting sealing socket 3. The fixed support sealing base 4 is fixed by anchor bolts,...

specific Embodiment approach 2

[0033] like Figure 1 to Figure 12 As shown, this embodiment further describes the first embodiment, the joint sealing socket 3 includes a fixed outer ring seat 3-1, three slope slots 3-2, two tapered racks 3-3 and a plurality of The sealing plate 3-4, the fixed outer ring seat 3-1 is fixedly connected to the inner end of the outer wall of the connecting pipe 1, and the outer wall of the fixed outer ring seat 3-1 is uniformly provided with three slope slots 3-2, two tapered The racks 3-3 are respectively fixedly connected to the two ends of the fixed outer ring seat 3-1, and the inner ends of the fixed outer ring seat 3-1 are evenly and fixedly connected to a plurality of sealing plates 3-4.

specific Embodiment approach 3

[0035] like Figure 1 to Figure 12 As shown, this embodiment further explains the second embodiment, the fixed support seal base 4 includes a fixed ring seat 4-1, two anchor anchor seats 4-2, two anchor threaded holes 4-3 , inner ring rack sliding groove 4-4, rack slider sliding groove 4-5, three T-shaped chute 4-6 and three rotating circular holes 4-7, fixed ring seat 4-1 lower end The two sides are respectively fixedly connected with two anchor holders 4-2, the anchor holder 4-2 is provided with an anchor threaded hole 4-3, and the inner ring rack sliding groove 4-4 is arranged on the fixed ring seat 4 In -1, the two ends of the inner wall of the inner ring rack sliding groove 4-4 are provided with a rack slider sliding groove 4-5, and the outer end of the fixed ring seat 4-1 is evenly provided with three T-shaped sliding grooves 4- 6. The outer end of the fixed ring seat 4-1 is evenly arranged, and the rotating circular hole 4-7 is arranged on the lower side of the T-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com