A method of saving material in the process of spin-coating impellers

A material-saving and spin-coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of material waste, achieve the effect of reducing pouring and saving coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The steps of the present invention are as follows:

[0021] 1. Make filler blocks according to the flow channel of the impeller:

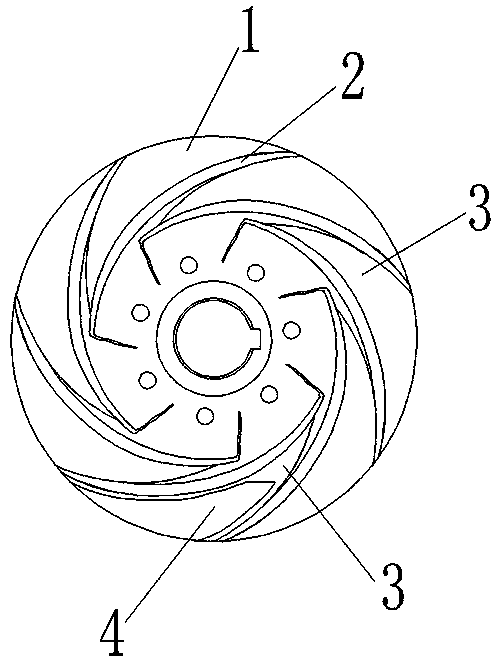

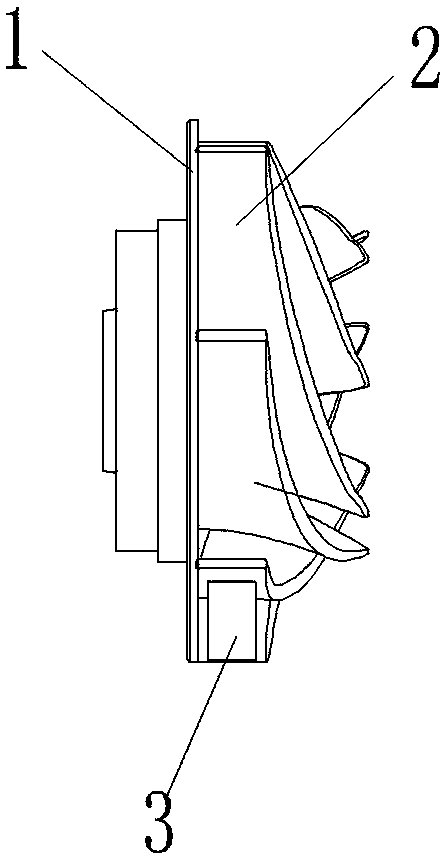

[0022] Such as figure 1 and figure 2 As shown, the impeller has a lower cover plate 1, an upper cover plate and several blades 2, and a flow channel 3 is formed between the lower cover plate 1, the upper cover plate and two adjacent blades 2, according to the shape of the inner space of the flow channel 3 The filler block 4 is made according to the shape, and there is a gap 5 between the peripheral side of the filler block 4 and the inner wall of the flow channel 3 .

[0023] 2. Make a flexible ferrule and fix the filling block on the ferrule:

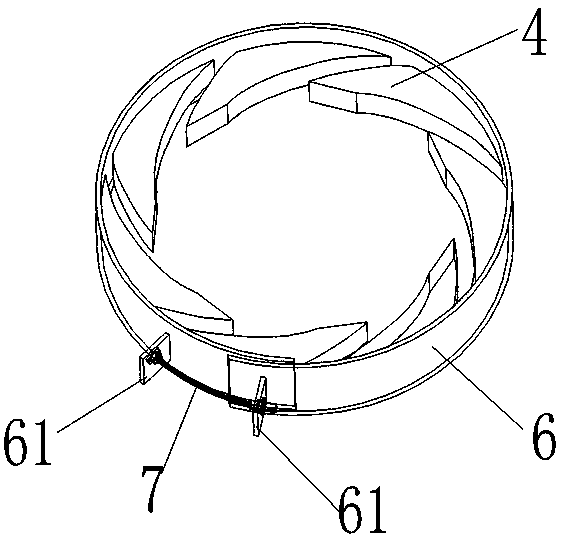

[0024] 2.1) First make the flexible metal hoop 6, weld two positioning buckles 61 to the two ends of the flexible metal hoop 6 respectively by electric welding, install and install the positioning bolt 7, as image 3 shown;

[0025] 2.2) Fix the filling block 4 evenly on the inner side of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com