Method for processing, manufacturing and constructing prefabricated small box girder hanging bracket

A construction method and manufacturing method technology, applied in bridges, bridge construction, load suspension components, etc., can solve problems such as material loss, difficulty in installing and fixing pre-embedded lifting points, and inability to lift small box girders with angles, and achieve processing Low cost, significant social and economic benefits, and the effect of reducing construction cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to fully clarify the advantages of the present invention, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The present invention takes the displacement, hoisting and installation of a prefabricated small box girder with a bottom width of 1.5m as an example.

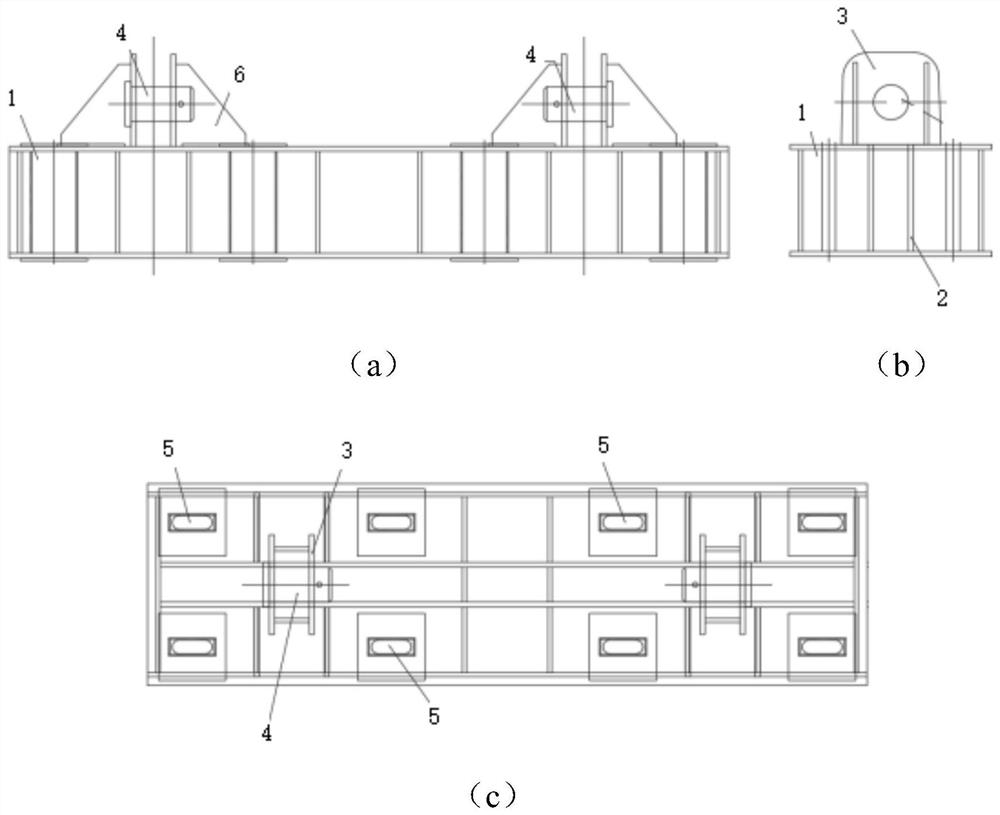

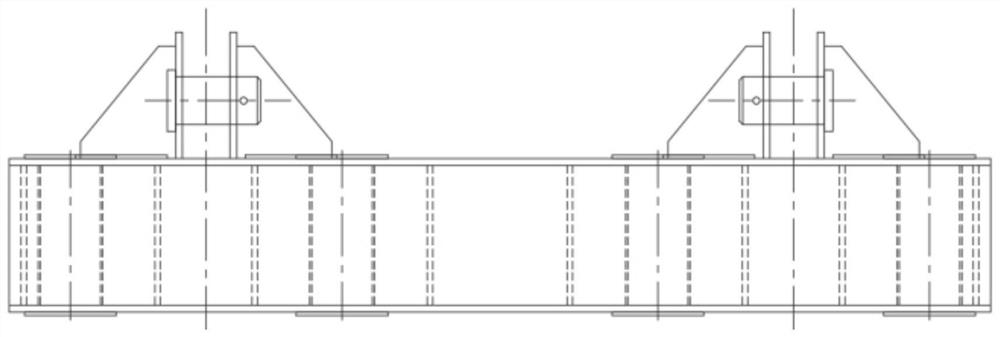

[0030] Such as figure 1 (a), (b), (c) in (a):

[0031] Set the cross-sectional size of the hanger according to the cross-sectional size of the small box girder. The hanger is mainly composed of three rectangular boxes. The reinforcing ribs 2 are arranged inside the box 1. Each hanger is equipped with two lifting lugs 3, and the holes for the lifting lugs 3 and hoisting Shaft pin 4 cross-sectional dimensions are set according to the lifting weight, and eight waist-shaped hoisting holes 5 are set on a hanger.

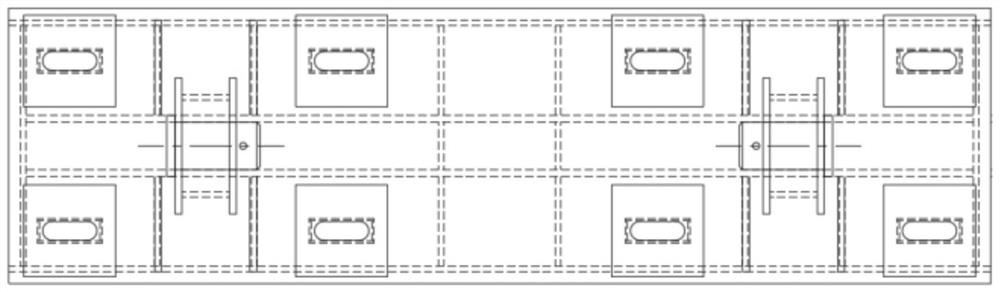

[0032] Such as figure 2 Shown:

[0033] The hole is surrounded by a thin steel plate, which is convenient for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com