Grout sleeve for steel bar connection and machining process of grout sleeve

A technology of grouting sleeve and processing technology, which is applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problem of uneven stress on a single spiral shear groove, difficulty in changing the temperature of the grouting sleeve, and reduce sleeve grouting Improve the quality of grouting construction, reduce processing defects, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

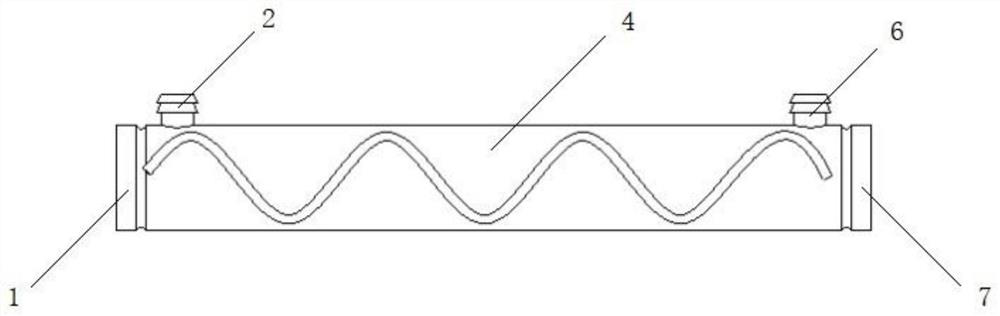

[0051] Using nodular cast iron to make the grouting sleeve 4 includes the following steps,

[0052] S1. Make grouting sleeve 4 modules and sand cores, and then make sand boxes;

[0053] S2. Smelting nodular cast iron according to the formula adjusted to meet the mechanical performance requirements to make molten iron, pouring and forming the grouting sleeve 4, turning over the casting after the casting is cooled to the requirements, and performing shot blasting and correction polishing;

[0054] S3. For the grouting sleeve 4 whose prefabricated installation end 7 is threaded, after the prefabricated installation end 7 is internally threaded, the upper groove pattern 9 and the lower groove pattern 10 are closely attached to the heat exchange circulation pipeline 11 , to complete the processing technology;

[0055] S4. For the grouting sleeve 4 connected by grouting at the prefabricated installation end 7, after the prefabricated installation end 7 does not need to be tapped, t...

Embodiment 2

[0057] Using a seamless steel pipe to make the grouting sleeve 4 includes the following steps,

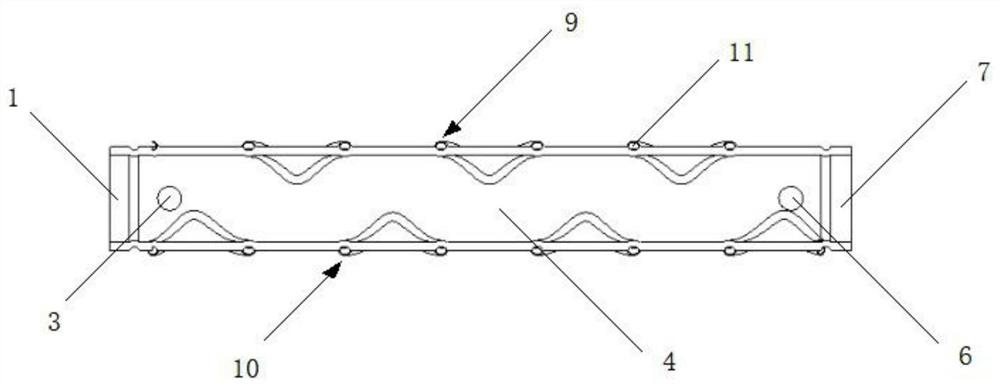

[0058] S1. Cut the seamless steel pipe to the design length, and use the button mold to extrude to form the annular groove, the upper groove pattern 9, the lower groove pattern 10 and the wave-shaped boss 8;

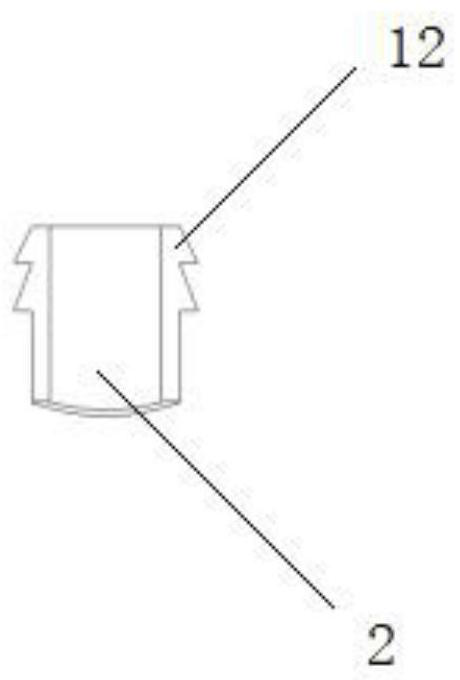

[0059] S2. Use a punching machine to punch holes at designated positions to form a slurry inlet through hole 2 and a slurry outlet through hole 5, install the slurry inlet conduit 3 with an annular protrusion at the slurry inlet through hole 2 and weld it firmly, and place the slurry inlet conduit 3 with an annular protrusion The slurry outlet conduit 6 is installed and fixed at the slurry outlet through hole 5;

[0060] S3. The upper groove pattern 9 and the lower groove pattern 10 are closely attached to the heat exchange circulation pipeline 11 to complete the processing technology.

Embodiment 3

[0062] Using a seamless steel pipe to make the grouting sleeve 4 includes the following steps,

[0063] S1. Cut the seamless steel pipe to the design length, clamp the seamless steel pipe in the mold in the hydraulic pliers of the reducing machine, and form annular grooves, upper groove lines 9, and lower groove lines through extrusion of the mold in the hydraulic pliers 10 and wave-shaped boss 8;

[0064] S2. Reduce the outer diameter of the prefabricated installation end 7 to the design value through secondary diameter reduction; perform internal thread tapping on the prefabricated installation end 7 to meet the design requirements; use a punching machine to punch holes at the designated position to form the through hole 2 and the pulp outlet through hole 5;

[0065] S3. Install the slurry inlet conduit 3 with the annular protrusion on the slurry inlet through hole 2 and weld it firmly, install the slurry outlet conduit 6 with the annular protrusion on the slurry outlet thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com