A transport device and transport method for coke oven refractories

A transportation method and technology of refractory materials, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of increasing operations, not being able to realize the practicality and difficulties of refractory material transportation, and achieve the reduction of refractory material loss and shorten Effect of construction period and self-weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

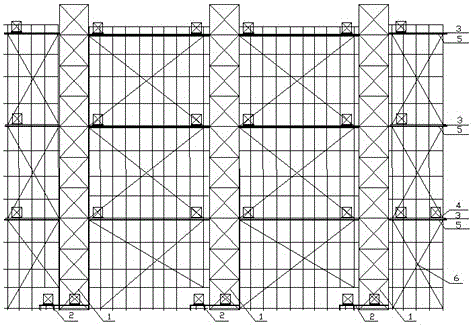

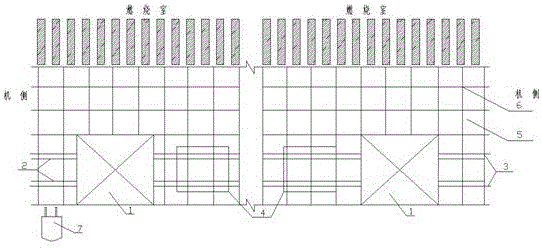

[0014] Referring to the accompanying drawings, a transportation device for coke oven refractory materials includes a material hoist 1, a lower rail 2, an upper rail 3, a rail car 4, a load-bearing platform 5 and a scaffolding 6, and the material hoist is arranged on the side of the coke oven machine. On the road, aligned with the outside of the full hall scaffolding, the load-bearing platform is laid on the full hall scaffolding, the lower track is installed in sections on the outer mouth of the material hoist and on the base, the upper track is installed on the load-bearing platform, and several track trolleys are respectively installed on the upper track and the lower track.

[0015] A method for transporting coke oven refractories, the specific technical scheme of which is:

[0016] A. Material hoist installation and commissioning: Install the material hoist along the furnace length on the side flue of the coke oven machine. The position is aligned with the outside of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com