Repair method for existing industrial factory building production equipment

A technology for production equipment and repair methods, applied in design optimization/simulation, special data processing applications, geometric CAD, etc., can solve problems such as reducing construction time, potential safety hazards, and reducing costs, to improve safety and installation efficiency. The effect of high and low construction cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] It is conducive to the understanding of the present invention, and the following will be described with reference to the accompanying drawings and examples.

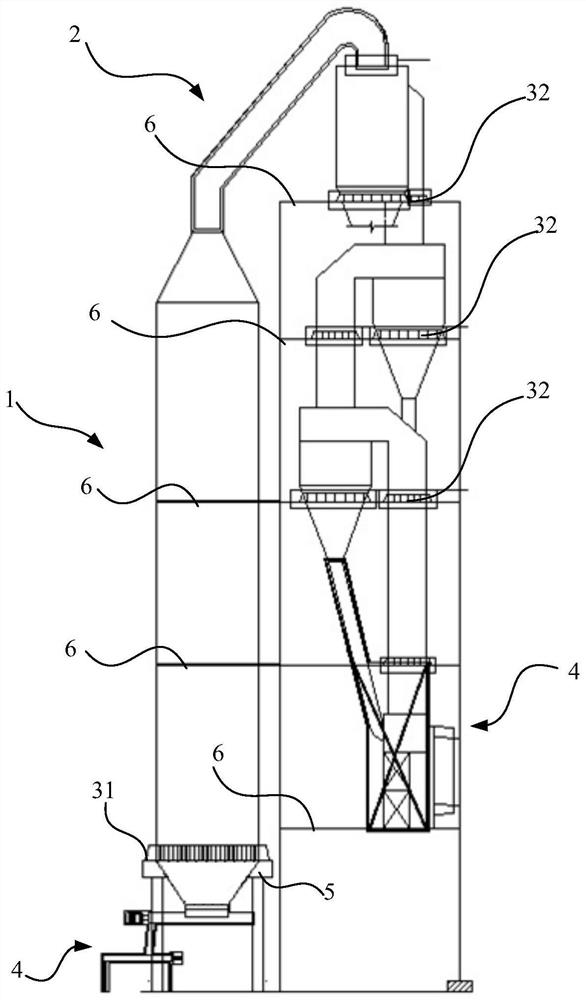

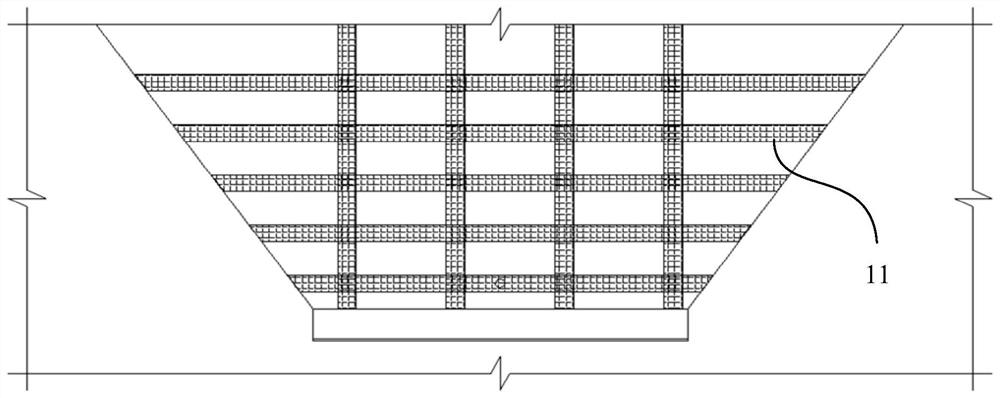

[0033] See figure 1 The present invention provides a repair method of existing industrial plant production equipment, and the production equipment 1 includes a plurality of members and a base 5 comprising the step of forming a three-dimensional scan for the production device 1 to form a model map, and according to the model map Determine the failure component with defects in the production equipment 1;

[0034] The base 5 is reinforced, and the support reinforcement of the production equipment 1 corresponds to the position of the failure member, and the failure member is removed;

[0035] Repairing the portion of the corresponding failure member in the model diagram, and then the replacement member 2 corresponding to the failure member is created according to the repaired model map, and the replacement member 2 corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com