Combinable telescopic sleeve jacking device and method thereof

A technology of telescopic sleeve and jacking device, which is applied in the fields of formwork/template/work frame, on-site preparation of building components, construction, etc., can solve the problem of the large number of transmission mechanisms, the complex power system, and the poor adaptability of the narrow cylinder space. and other problems, to achieve the effect of reducing construction cost input, improving construction efficiency and ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

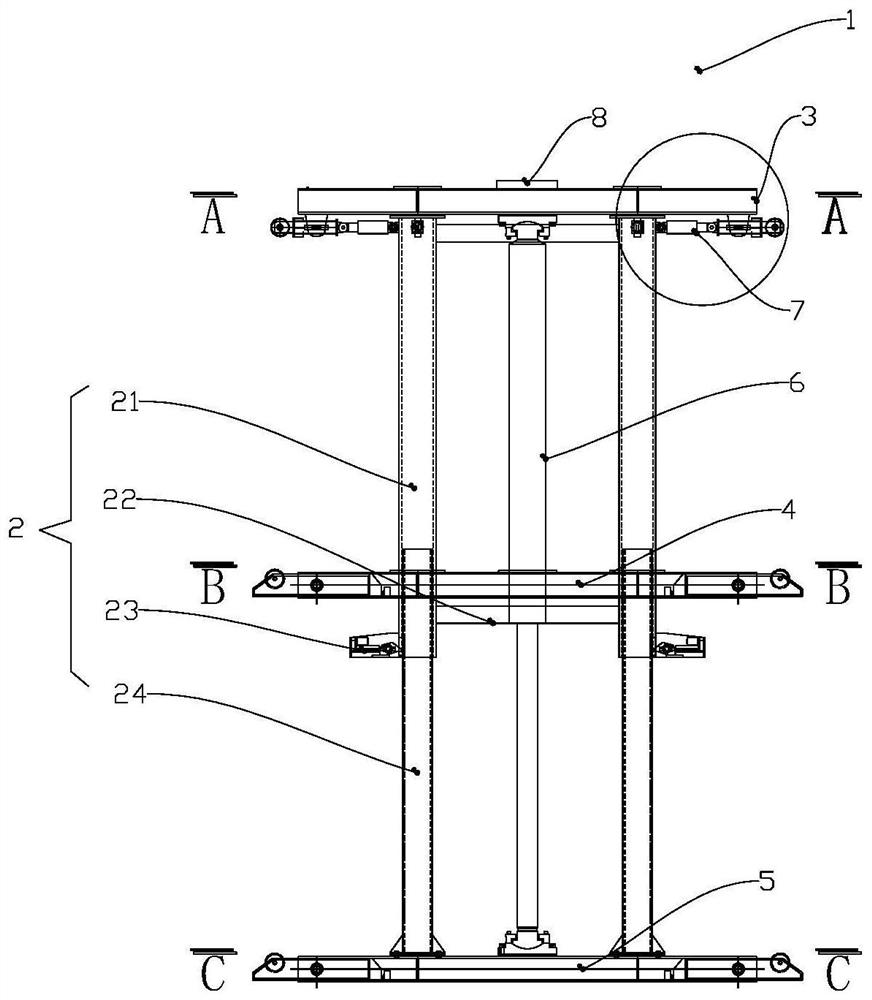

[0051] Combine below Figure 1 to Figure 17 A combinable telescopic sleeve jacking device and method of the present invention will be described in detail.

[0052] Please refer to Figure 1 to Figure 17 , a combinable telescopic sleeve jacking device 1, comprising a number of jacking unit modules, a horizontal jacking frame 3, an upper support frame 4, a lower support frame 5 and several longitudinal connecting beams 9,

[0053] The jacking unit module includes a jacking cylinder 6 and a telescopic sleeve frame 2; the jacking cylinder 6 is arranged at the center of the telescopic sleeve frame 2, and its upper end is connected with the horizontal jacking frame 3, and the jacking cylinder 6 supports the longitudinal direction of the frame 4 from the upper end. The gap between the connecting beams 9 passes through, and its lower end is connected with the lower support frame 5;

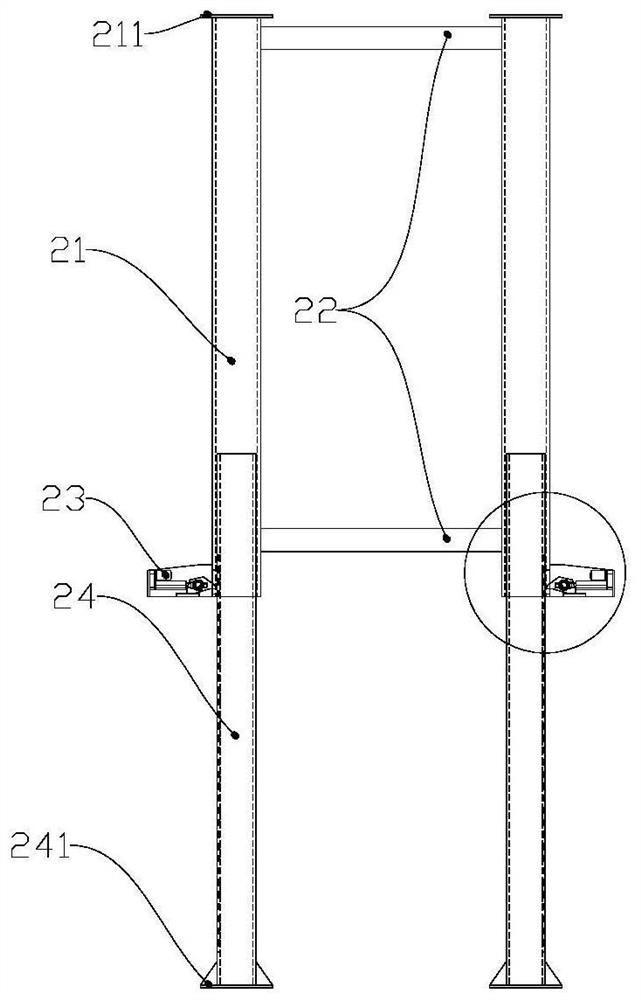

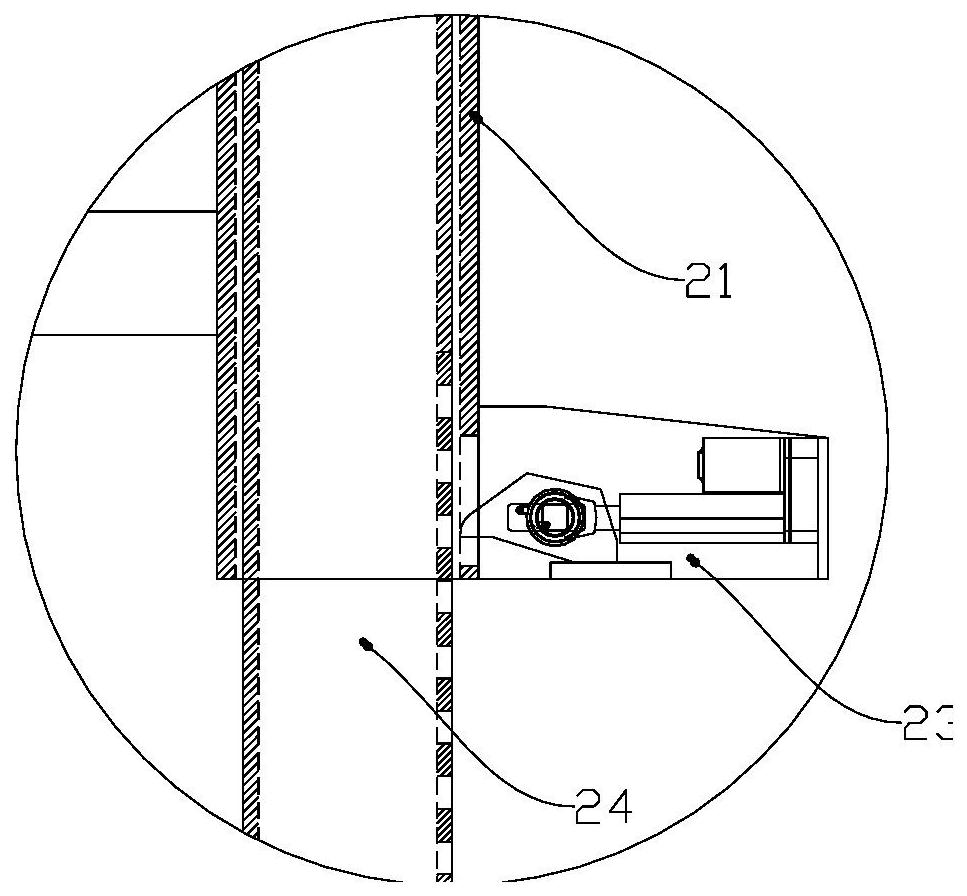

[0054] The telescopic sleeve frame 2 includes a sleeve rod 21, a telescopic sleeve frame connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com