Advanced commercial vehicle gear shifting reminding control method and system

A control method and technology for commercial vehicles, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., can solve the problems of small difference in transmission ratio of each gear, frequent prompts for adding and subtracting gears, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

[0032] refer to figure 2 , 3 , an advanced commercial vehicle shift reminder control method, comprising the following steps:

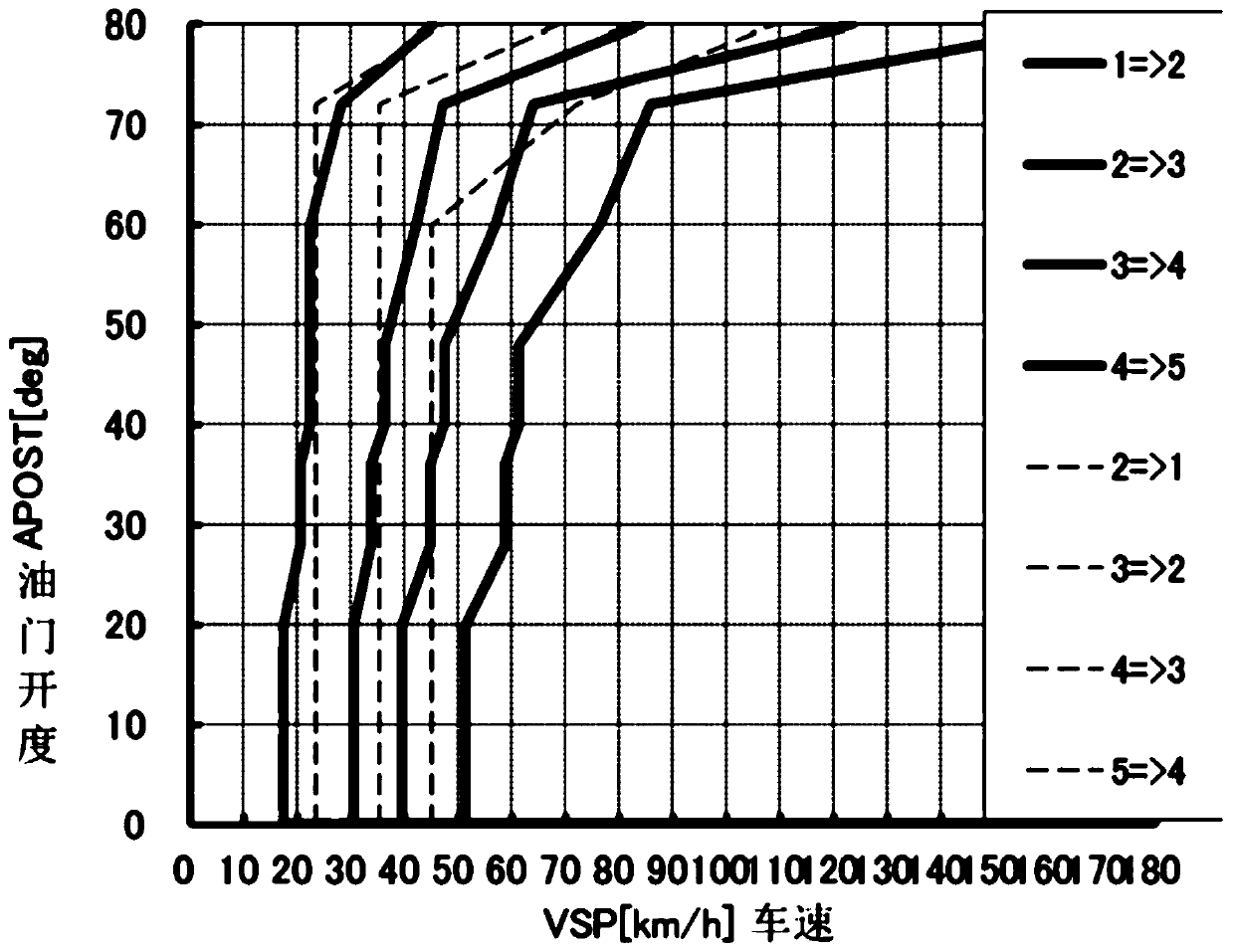

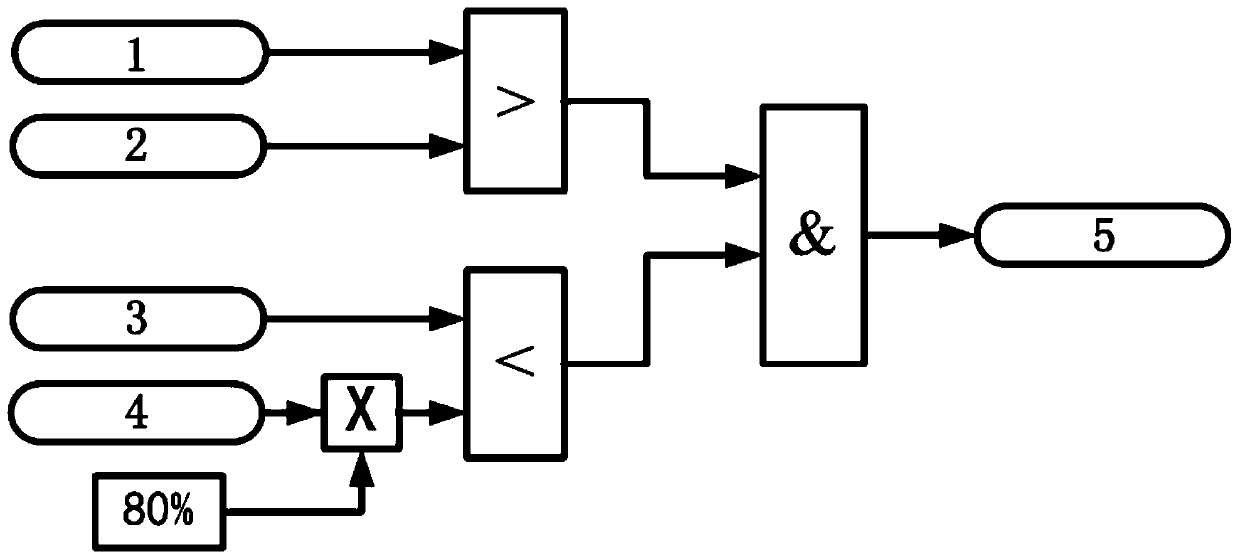

[0033] S1. When the vehicle speed is lower than the threshold, calculate the engine speed and the maximum engine torque after the upshift, and if the engine speed and the maximum engine torque meet the requirements, remind the driver to upshift;

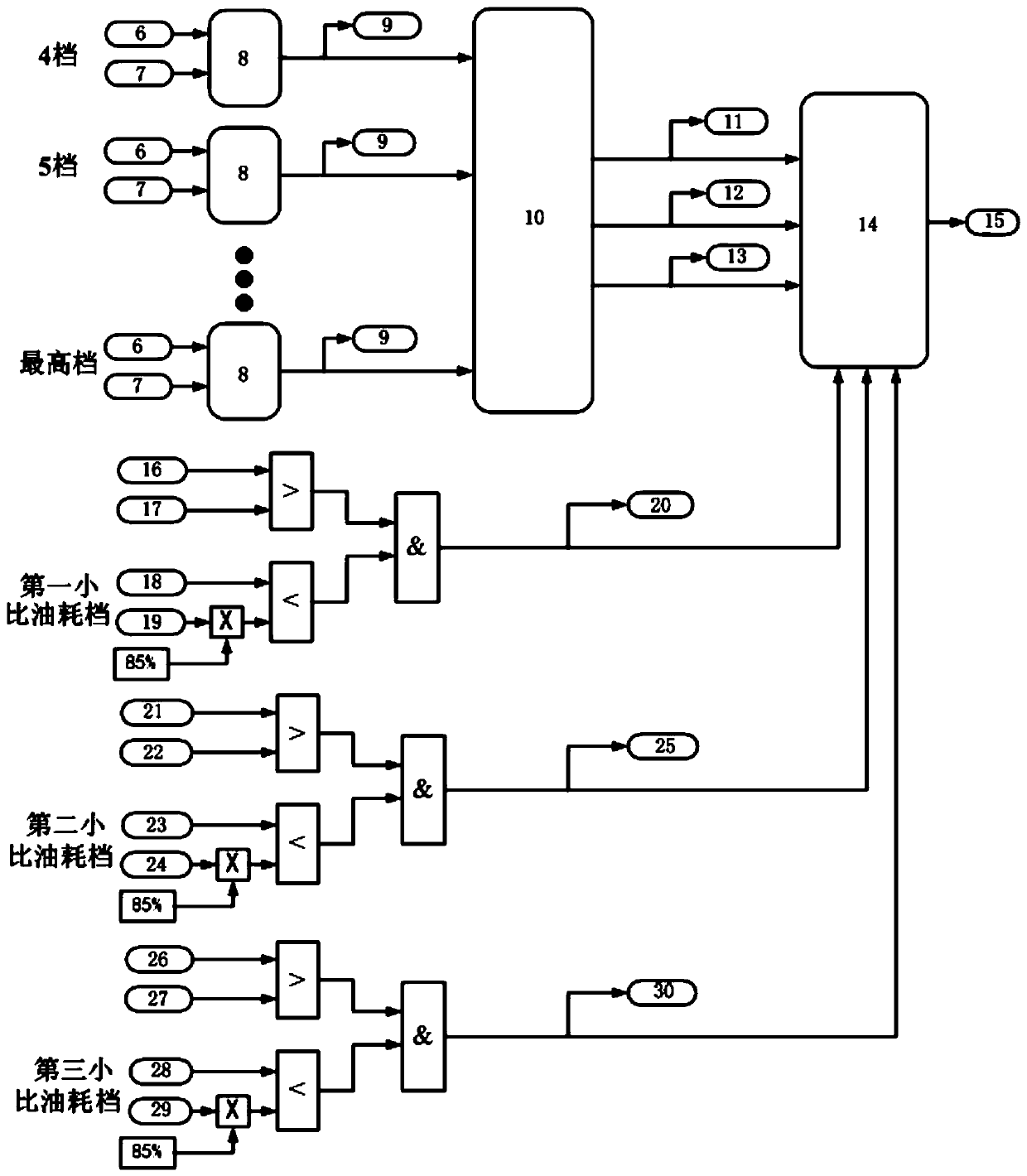

[0034] S2. When the vehicle speed is not less than the threshold value, calculate the engine speed, engine maximum torque and specific fuel consumption of each gear and obtain the first small specific fuel consumption gear, the second small specific fuel consumption gear, and the third small specific fuel consumption gear; Under the condition that the maximum torque of the engine meets the requirements, the optimal gear is selected from the first small specific fuel cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com