Condenser assembly and its control method, oil return assembly and air conditioner

A condenser component and control method technology, applied in refrigeration components, evaporator/condenser, refrigeration and liquefaction, etc., can solve the problem of poor lubricating effect of lubricating oil, incomplete evaporation of refrigerant, incomplete separation of lubricating oil and refrigerant, etc. problem, to achieve the effect of not reducing the heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

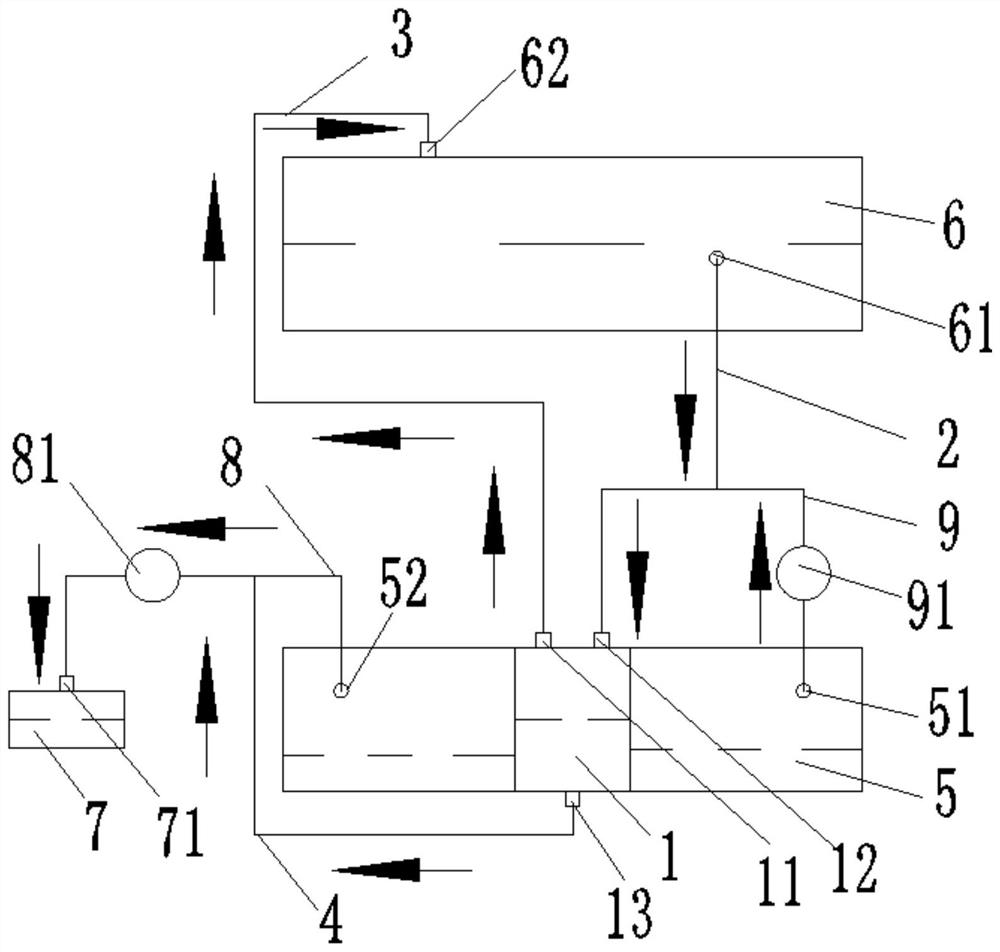

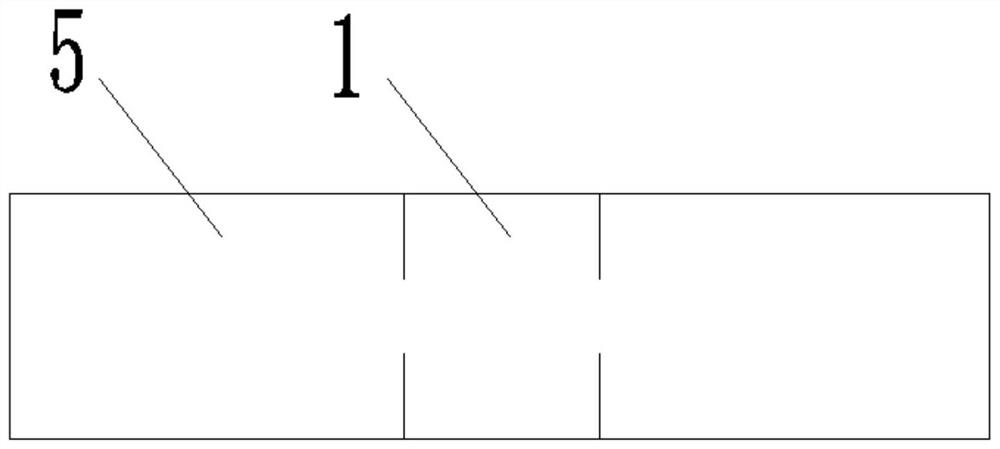

[0039] see in conjunction figure 1 As shown, according to the embodiment of the present application, a condenser assembly includes: a condenser body 5 and an oil return structure, the oil return structure includes a separation chamber 1; the separation chamber 1 is arranged inside the condenser body 5; the separation chamber 1 It is used to separate the mixture of refrigerant and lubricating oil; the drainage assembly is used to guide the mixture of refrigerant and lubricating oil into the separation chamber 1, guide the separated oil to flow to the oil tank 7, and guide the separated refrigerant to flow back to the refrigeration unit. system, this application utilizes the high-temperature gas in the condenser body 5 to exchange heat with the mixture of oil and refrigerant in the separation chamber 1, so that the separation of the lubricating oil and the refrigerant is more thorough, and the refrigerant evaporates in the separation chamber 1 without reducing The temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com