Wire tightener chuck and wire tightening method thereof

A kind of wire tensioner and collet technology, applied in the field of electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

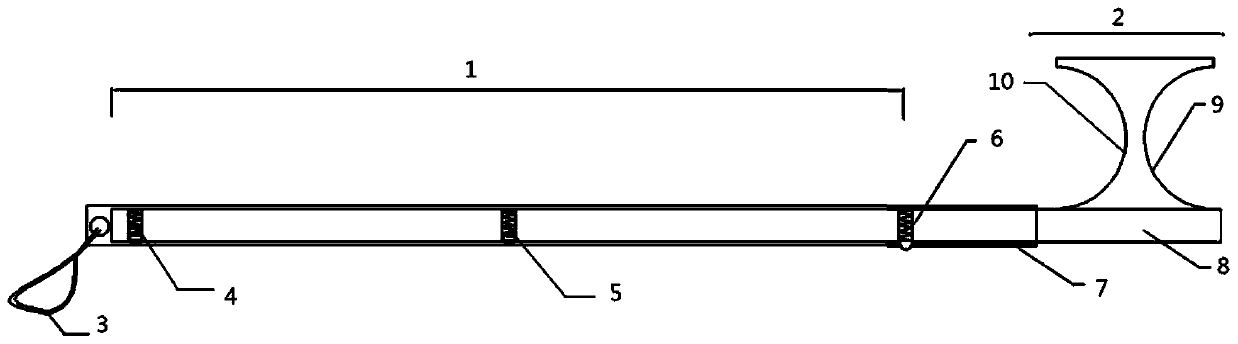

[0038] The embodiment is basically as attached figure 1 Shown: the chuck of the wire tensioner, including the chuck structure 1 used to contact the wire tensioner and the telescopic rod structure 2 used to connect the chuck structure 1; the chuck structure 1 includes a hook with a positive and negative two-way contact surface; The telescopic rod structure 2 includes an inner rod 8 and an outer rod 7 which are coaxially arranged and can move relative to each other.

[0039] The hook has a positive contact surface 9 and a reverse contact surface 10, and the positions of the two contact surfaces are opposite. Both the positive contact surface 9 and the reverse contact surface 10 are arc surfaces. The positive contact surface 9 is the side away from the end of the outer rod 7 , and the reverse contact surface 10 is the side near the end of the outer rod 7 .

[0040] The two opposite contact surfaces can be conveniently contacted with the wire tensioner from two opposite position...

Embodiment 2

[0058] The difference between this embodiment and the first embodiment is that at least two sliding grooves distributed along the length direction of the outer rod are formed on the outer surface of the outer rod, and a sliding ring that can move along the direction of the sliding grooves is sleeved on the sliding grooves. The sliding ring has a ring structure, and the inner surface of the sliding ring is integrally formed with a radially inwardly protruding sliding part, which extends into the chute through the sliding part, so that the sliding ring can be sleeved on the outer rod and at the same time make the sliding ring Able to slide along the chute, in the length direction of the outer rod. The number of slide ring sliding parts is the same as the number of chute.

[0059] A plurality of threaded holes are opened on the sliding ring, and each threaded hole is connected with a screw, and the fixed ring is connected with the screw, and an air cavity that can be inflated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com