Three-stage energy dissipation ship chamber nested in ship lock chamber and ship lockage method

A technology of ship compartment and lock chamber, which is applied to ship locks, vertical lifting ship machinery, ship lifting devices, etc., can solve the problems of rising project cost and construction difficulty, increasing resistance coefficient of water delivery system, affecting the passing capacity of ship locks, etc., and achieves improvement. The berthing conditions of ships, the effect of shortening the opening and closing time, and shortening the passage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

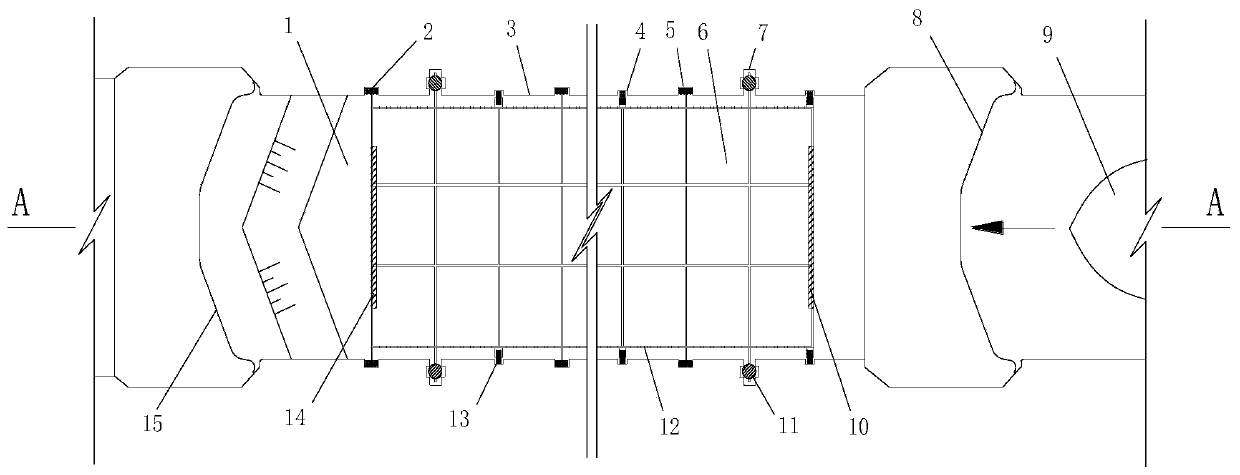

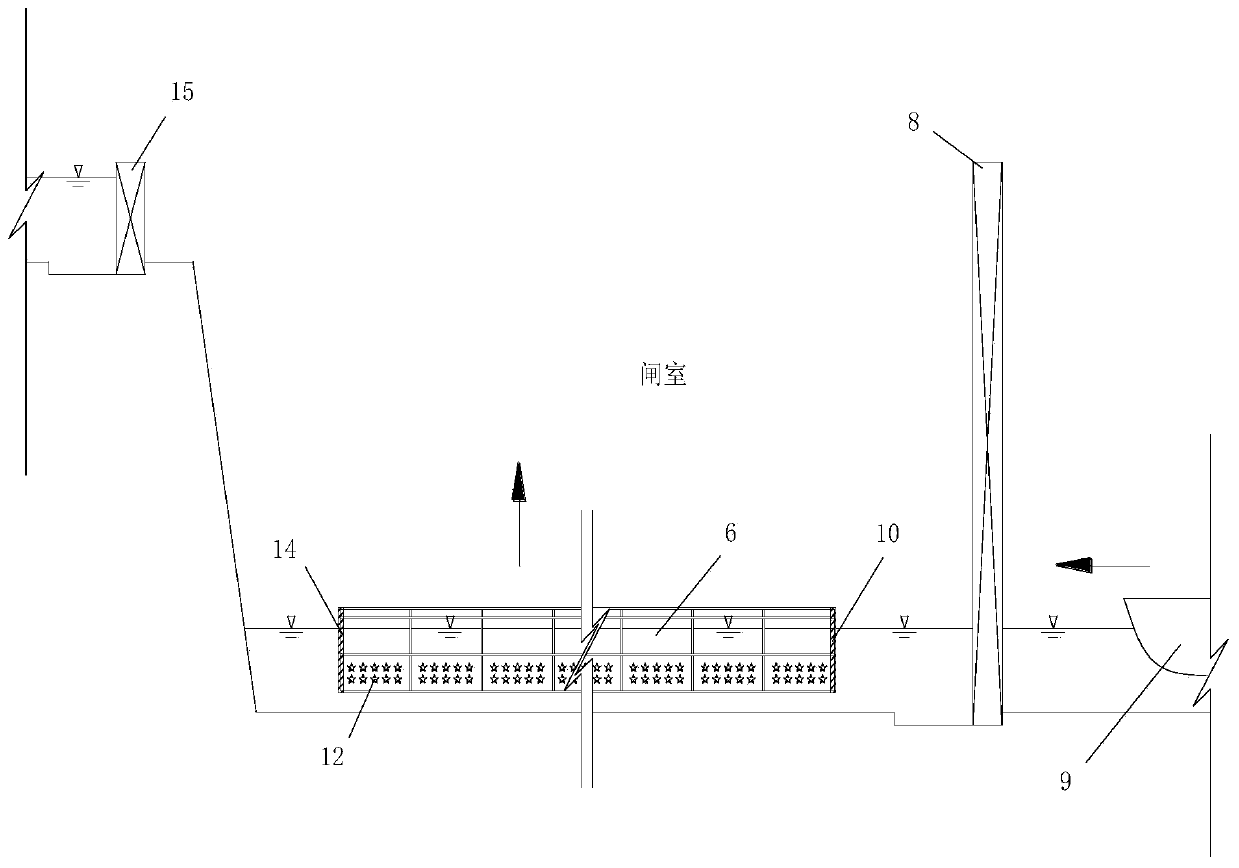

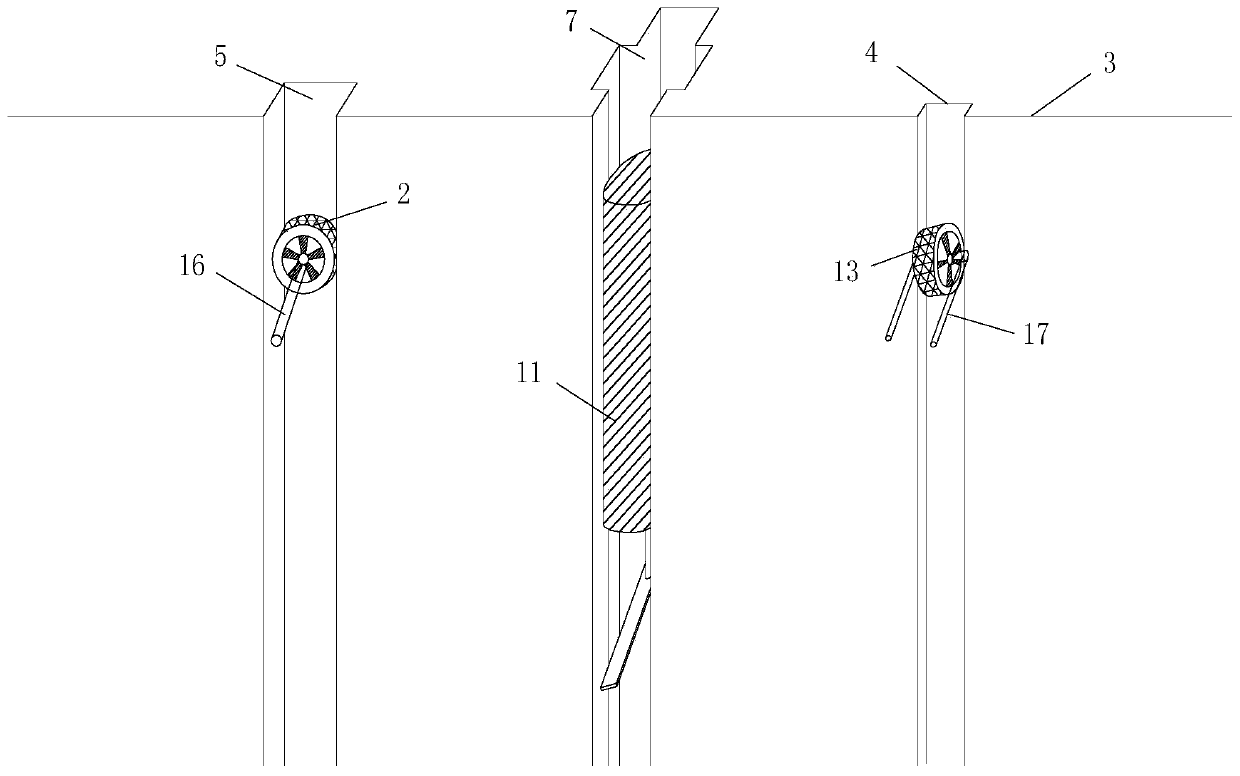

[0075] The present invention is an example of a ship lock project with a design water head of 40.25m and a lock chamber 1 scale of 265m × 34m × 5.8m.

[0076] The traditional design scheme is: in order to ensure the safe berthing conditions of the ship 9, it is necessary to adopt the top water outlet of the eight vertical branch corridors with four sections and cover plates to dissipate the energy. m=55m 2 , the total cross-sectional area of the main corridor is 2×5m×7m=70m 2 , the total water outlet area of the top seam is 112×5.2m×0.18m=104.83m 2 . According to the calculation, the opening time of the valve needs to be set to 8 minutes, the total resistance coefficient of the irrigation section is 1.8, the flow coefficient is 0.75, and it takes 879 seconds for the ship lock to complete one irrigation.

[0077] The design scheme of the present invention is as follows: the scale of the ship box body 6 is designed to be 261m×32m×6.7m, the energy dissipation holes 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com