Wrap spring and wrap spring assembly

A winding, equipment technology, applied in the direction of springs, springs/shock absorbers, coil springs, etc., can solve problems such as gaps or gaps that cannot be compensated, and achieve the effect of prohibiting premature failure, preventing switching angle, and preventing improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

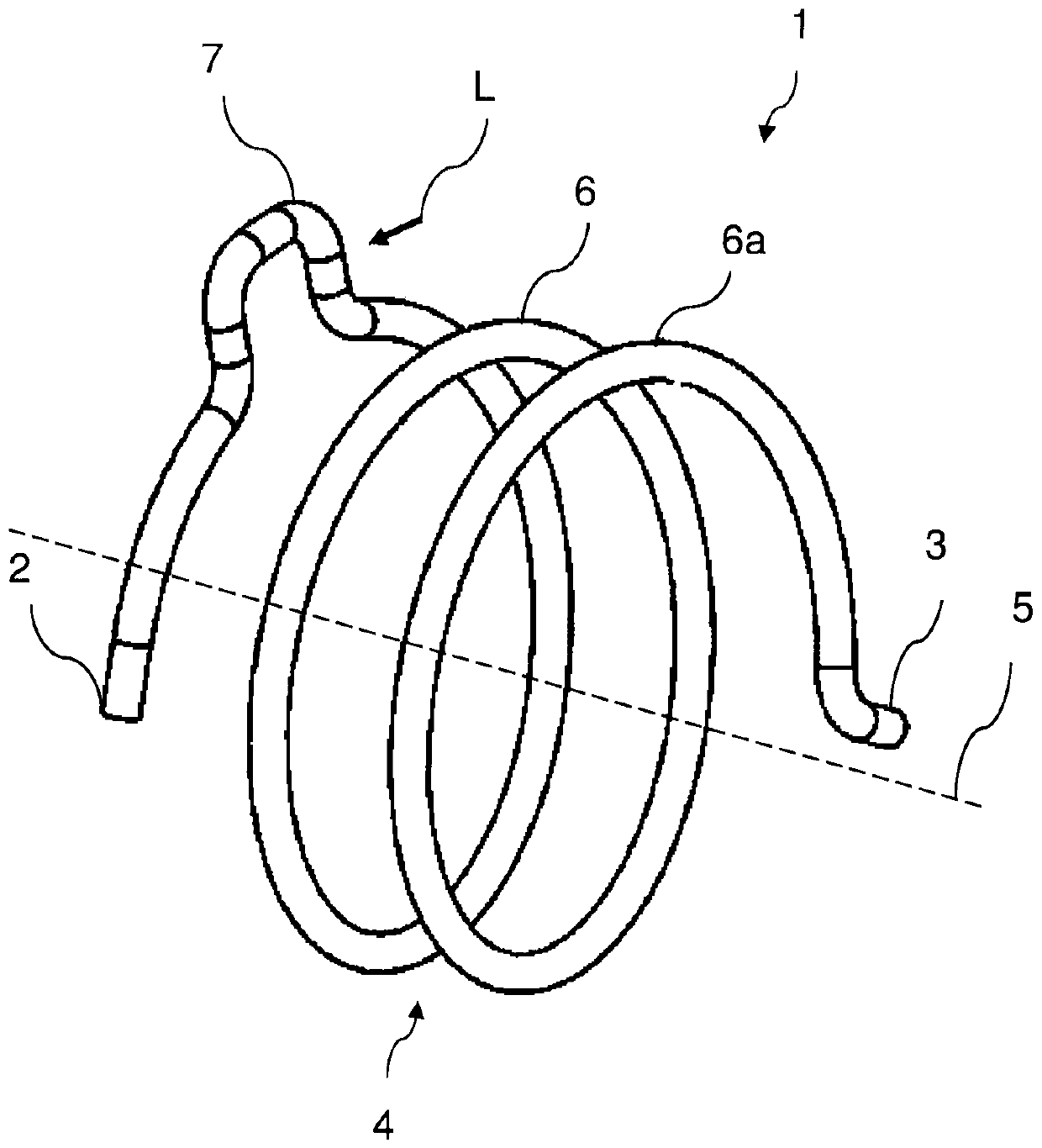

[0033] according to figure 1 The coil spring 1 has a coil spring first end 2, a coil spring second end 3 and is arranged between the coil spring first end 2 and the coil spring second end 3 The coiled spring section 4. The wrap-around spring section 4 is divided into two wrap-around spring turns 6 , 6 a. The first end 2 of the wrap spring extends over 90 degrees in the circumferential direction. Thus, the switching angle of the readjustment device 10 (not shown) can be halved compared to the prior art. The first coil 6 of the wrap spring has a U-shaped projection 7 . The introduction of a load L on the U-shaped projection 7 leads to a bending moment on the U-shaped projection 7 which deforms slightly under load. As a result, a radial force is formed on the side of the U-shaped projection 7 opposite the load introduction L which prevents further deformation and limits bending on the side of the load introduction L moment.

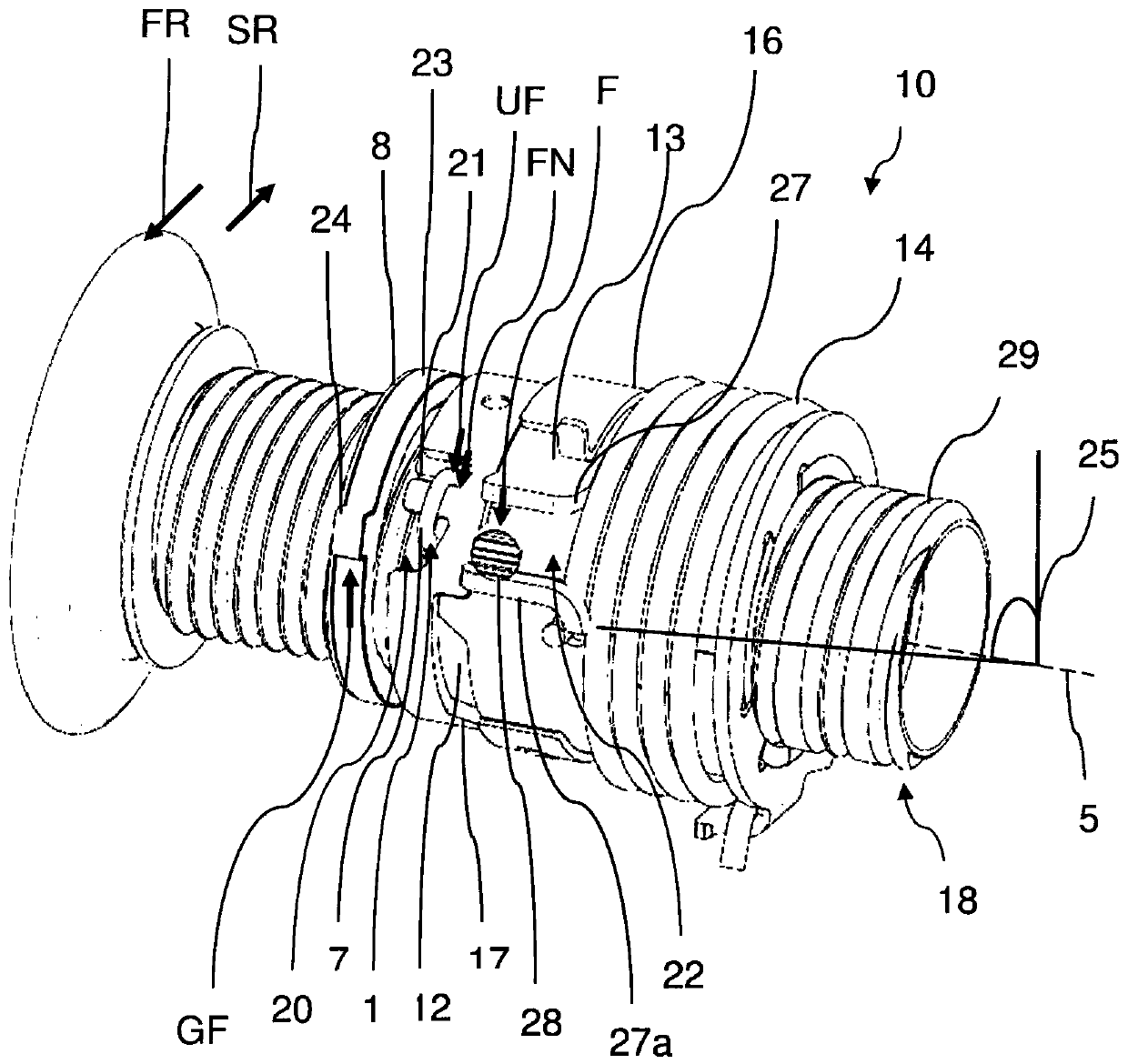

[0034] figure 2 It shows how the wrap spring 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com