A steering transmission system and vehicle

A steering transmission and bogie technology, which is applied to vehicle parts, steering mechanisms, steering tie rods, etc., can solve the problem of machining errors and the inability of the steering tie rods to be properly connected between the steering knuckle arm and the corresponding intermediate rocker arm, and the steering tie rod. Long end distance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

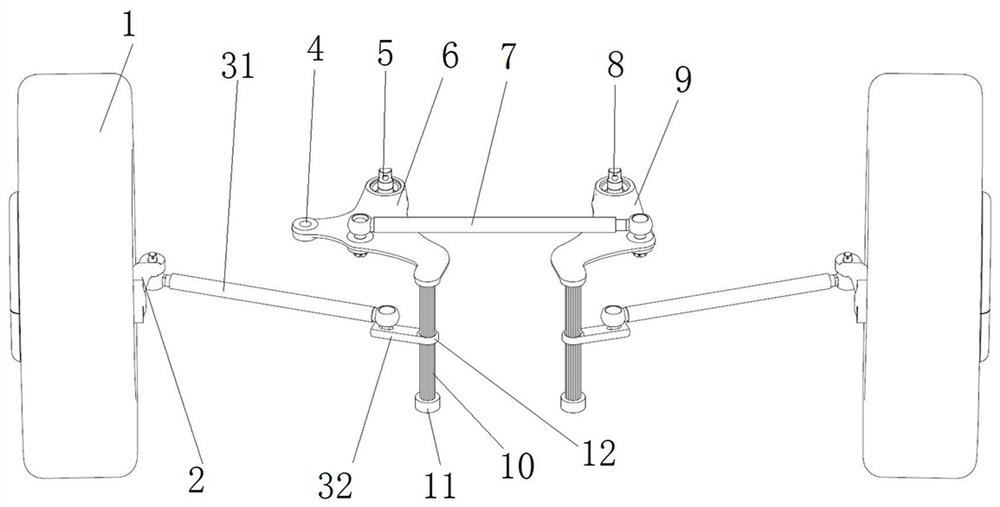

Embodiment 1

[0068] like figure 1 As shown, the steering transmission system is arranged between two wheel assemblies 1 . The steering transmission system includes a bogie, a knuckle arm tie rod and a steering knuckle arm 2, the bogie is fixedly connected with a vertical arm 10, and the knuckle arm tie rod includes a first tie rod unit 31 and a second tie rod unit 32, and the second tie rod unit 32 is far away from the first tie rod unit. One end of a tie rod unit 31 is slidably fitted on the vertical arm 10, and the end of the first tie rod unit 31 away from the second tie rod unit 32 is hinged to the end of the steering knuckle arm 2; the number of steering knuckle arms 2 is two, and each steering knuckle The end of the arm 2 away from the first tie rod unit 31 is fixedly connected to the steering knuckle of the corresponding wheel assembly 1, so that when the bogie rotates, the knuckle arm tie rod is driven to drive the knuckle arm 2 to move, thereby realizing the steering of the wheel ...

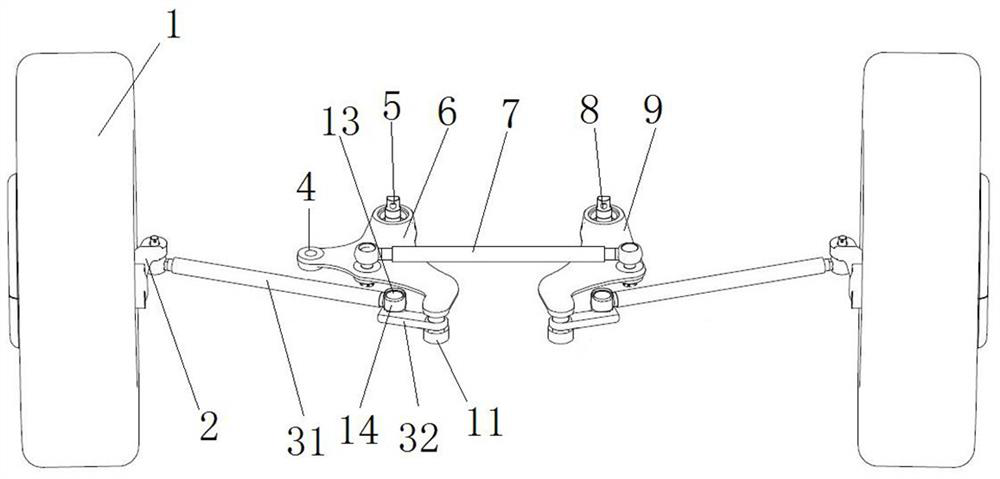

Embodiment 2

[0077] like figure 2 As shown, the difference from Embodiment 1 is that, taking the left side as an example, one end of the second tie rod unit 32 is hinged on the driving arm 6, and the other end of the second tie rod unit 32 is provided with a spline shaft 13, the first One end of the tie rod unit 31 is hinged on the steering knuckle arm 2, and the other end is provided with a spline sleeve 14, and the spline sleeve 14 on the first tie rod unit 31 is sleeved on the spline shaft 13 on the second tie rod unit 32, so as to Adjustment of the angle between the first rod unit 31 and the second rod unit 32 in the horizontal direction is realized. In other embodiments, the spline shaft can be arranged on the first tie rod unit, and the spline sleeve can be arranged on the second tie rod unit.

[0078] It should be noted that the spline shaft and the spline sleeve in this embodiment cannot move relative to each other in the axial direction of the spline shaft.

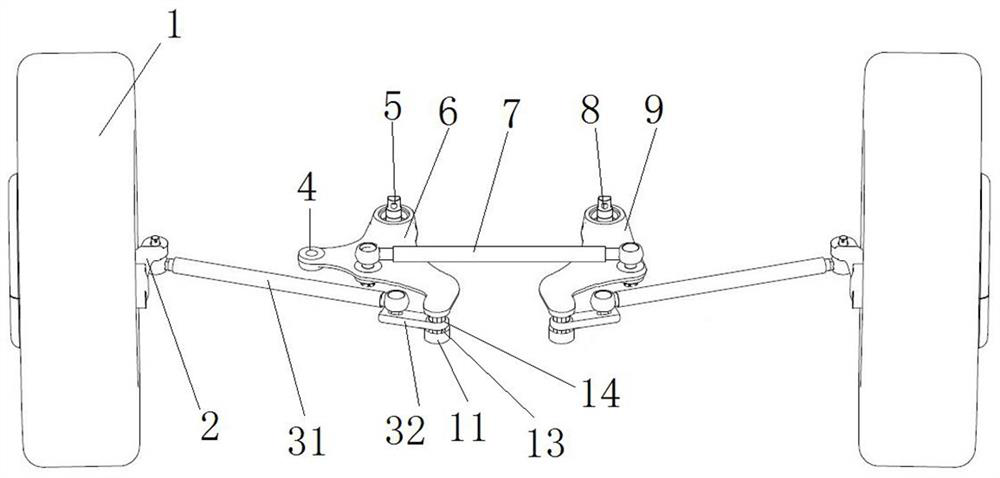

Embodiment 3

[0080] like image 3 As shown, the difference from Embodiment 1 is that the vertical arm 10 is a spline shaft, the length of the spline shaft is relatively short, and the second pull rod unit 32 is limited between the stopper 11 and the driving arm 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com