High-position storage equipment and unmanned system comprising same

A storage device and a high-level technology, applied in the field of unmanned projects, can solve the problems of being unable to realize full automation, and achieve the effects of fully automatic storage, high storage volume ratio and site utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

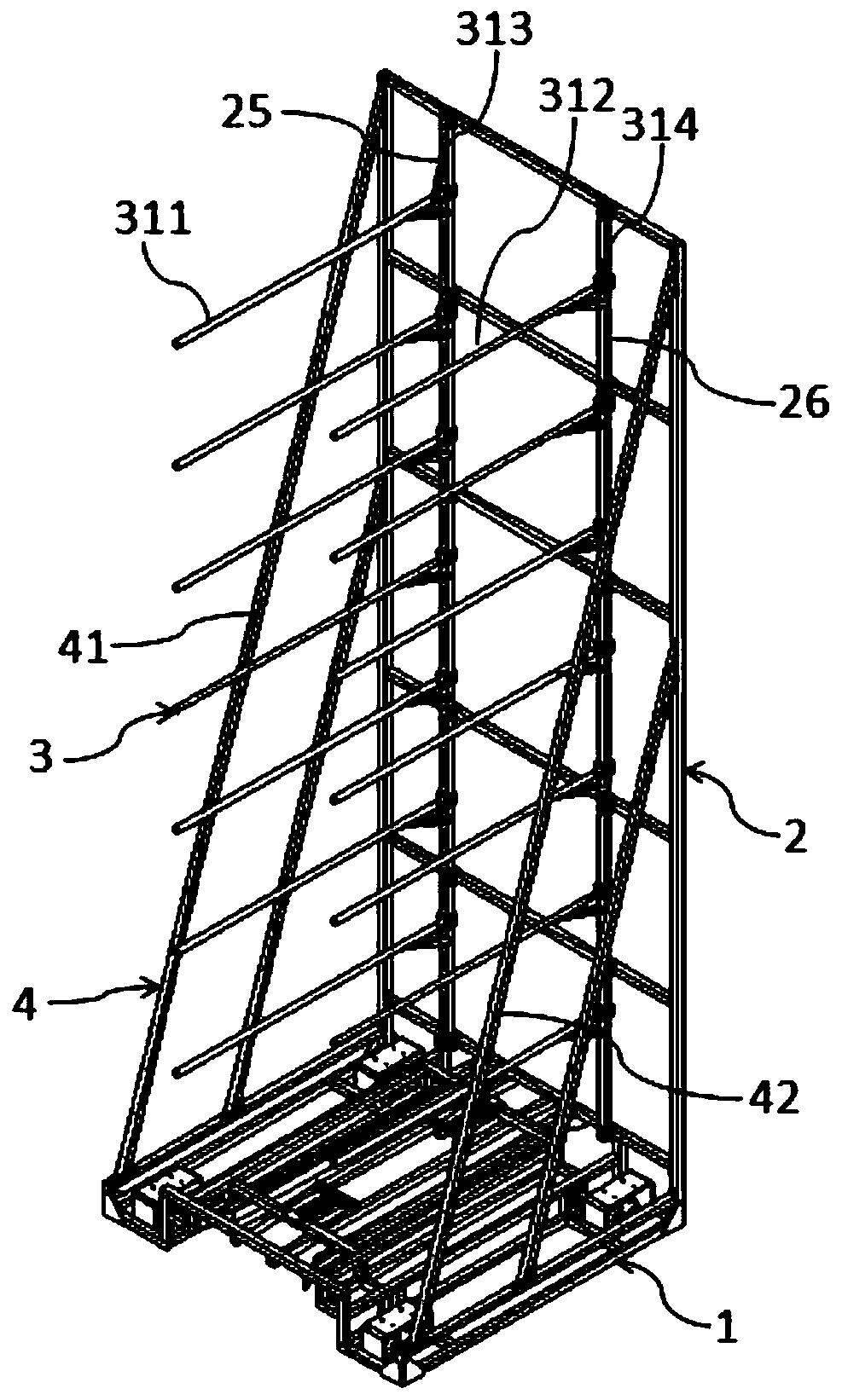

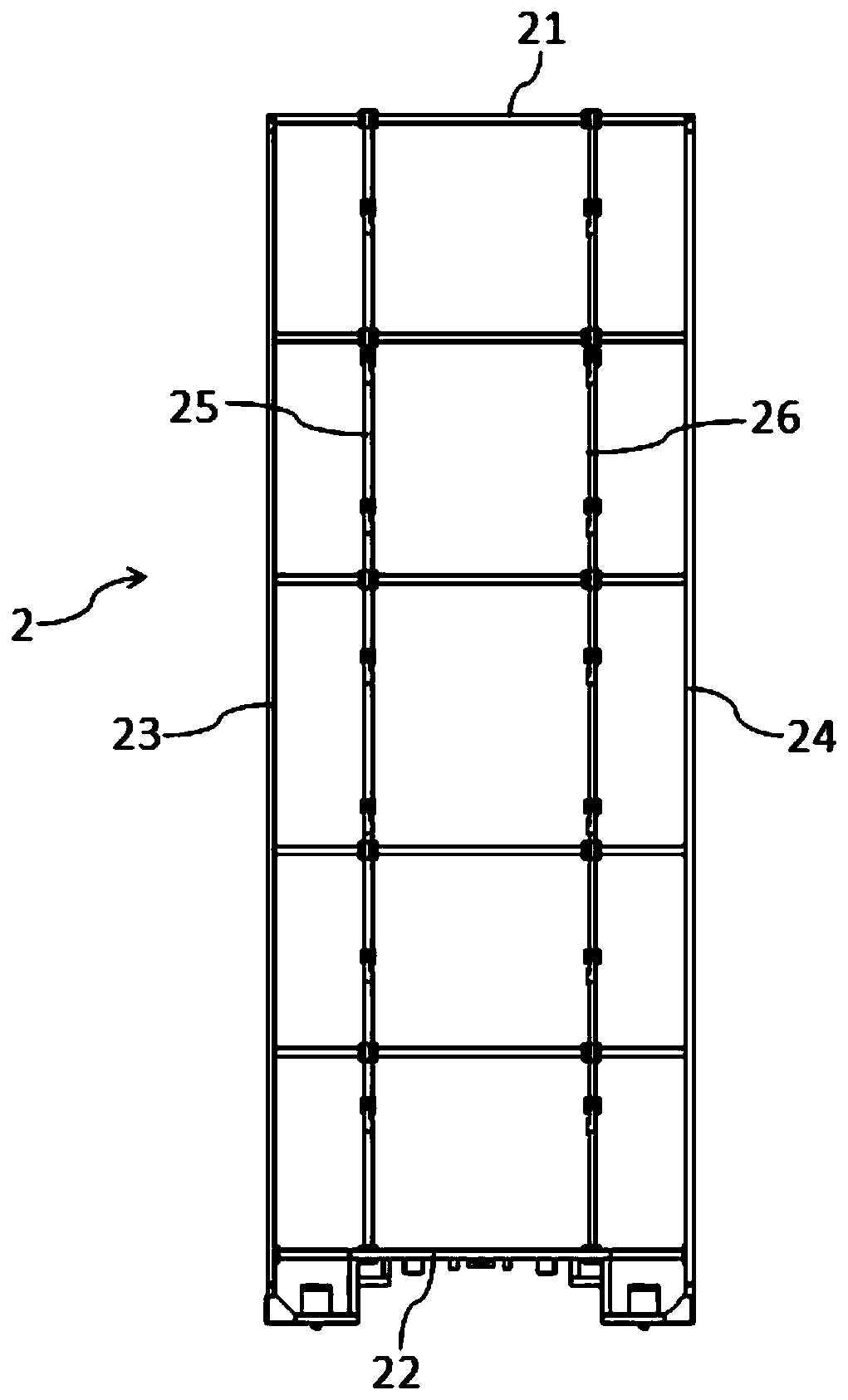

[0020] Such as figure 1 As shown, the high storage device according to a preferred embodiment of the present invention includes a chassis 1, a support back 2 and a rod structure 3, wherein the support back 2 is vertically fixed on the chassis 1, and the rod structure 3 is vertically fixed on the support back 2.

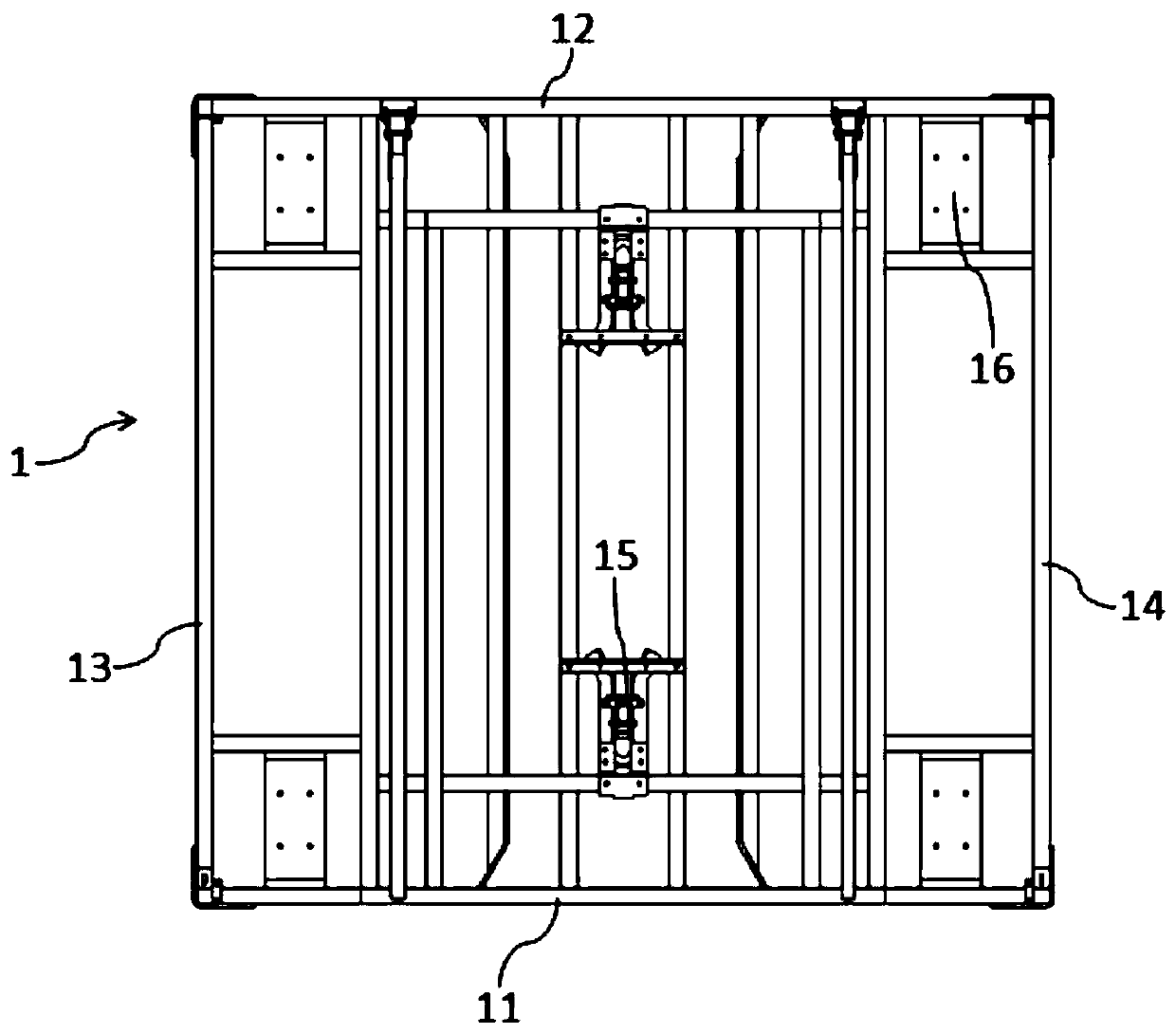

[0021] Such as figure 2 As shown, the chassis 1 has a rectangular cross section with a first free side 11, a first connecting side 12, a first side 13 and a second side 14, wherein the first free side 11 and the first connecting side 12 are spaced from each other The first side 13 and the second side 14 are spaced apart from each other and are arranged between the first free side 11 and the first connecting side 12 and connect the first free side 11 and the first connecting side 12 . In addition, the chassis 1 has a hooking mechanism 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com