Emergency stop triggering device for steel strand folding forming

A technology of triggering device and steel strand, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc., can solve problems such as affecting baling forming, affecting operation, and working fatigue, and achieves good practical use value. Eliminate cumbersome and laborious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

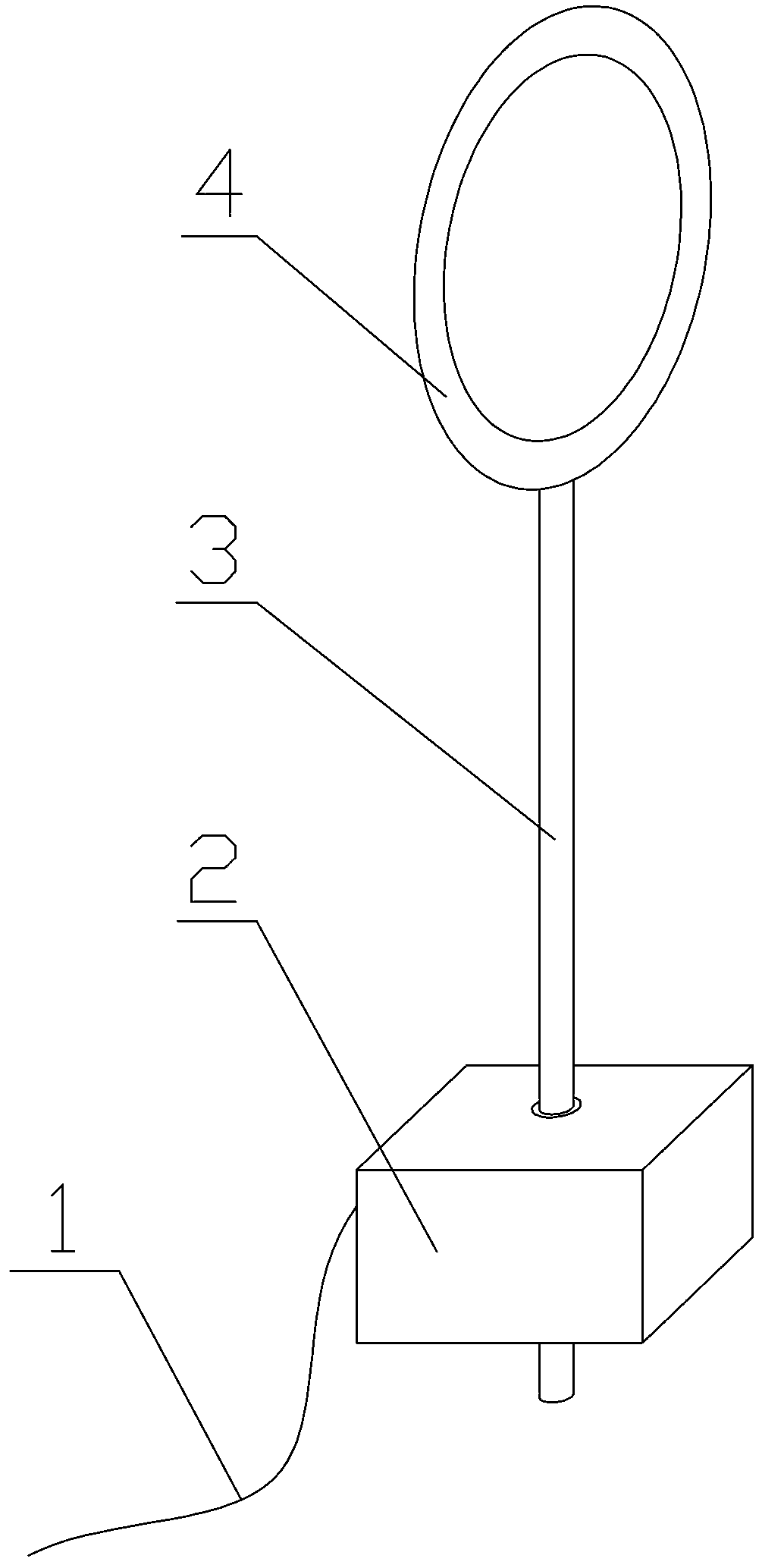

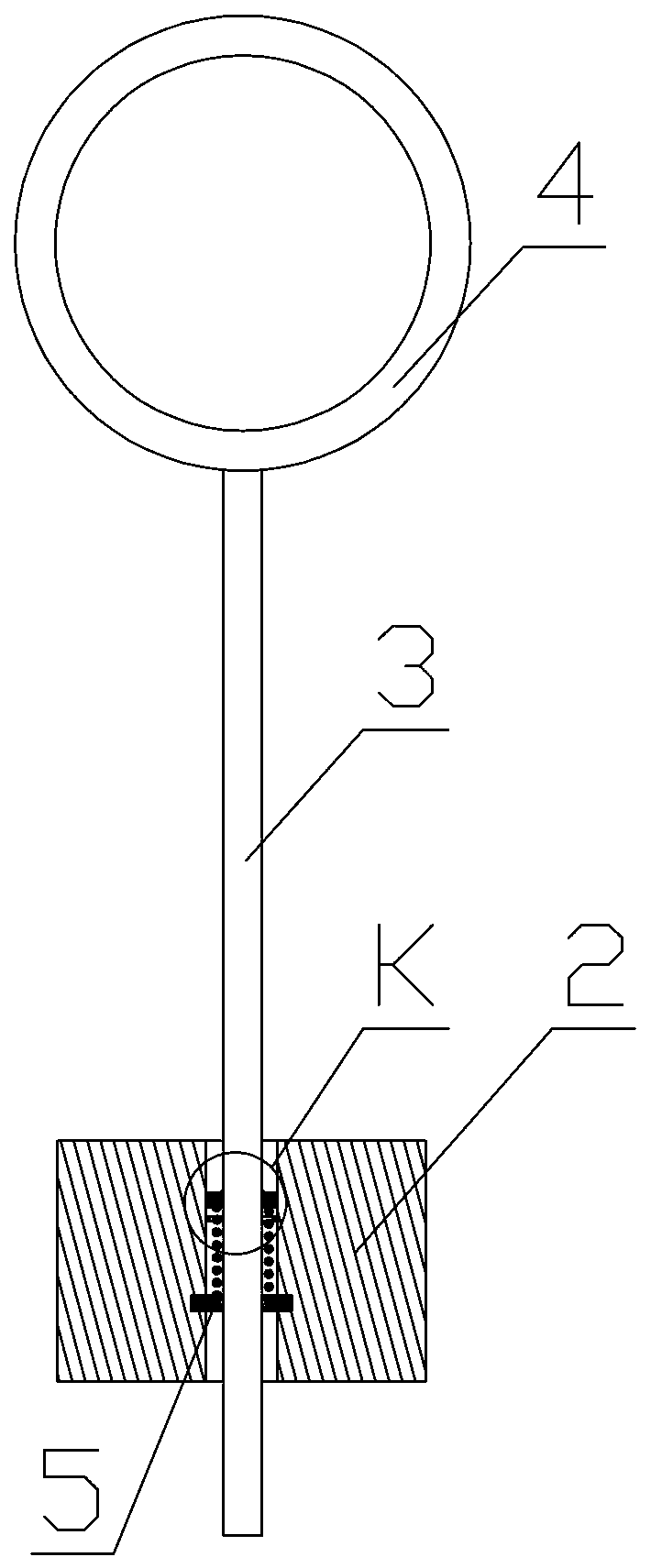

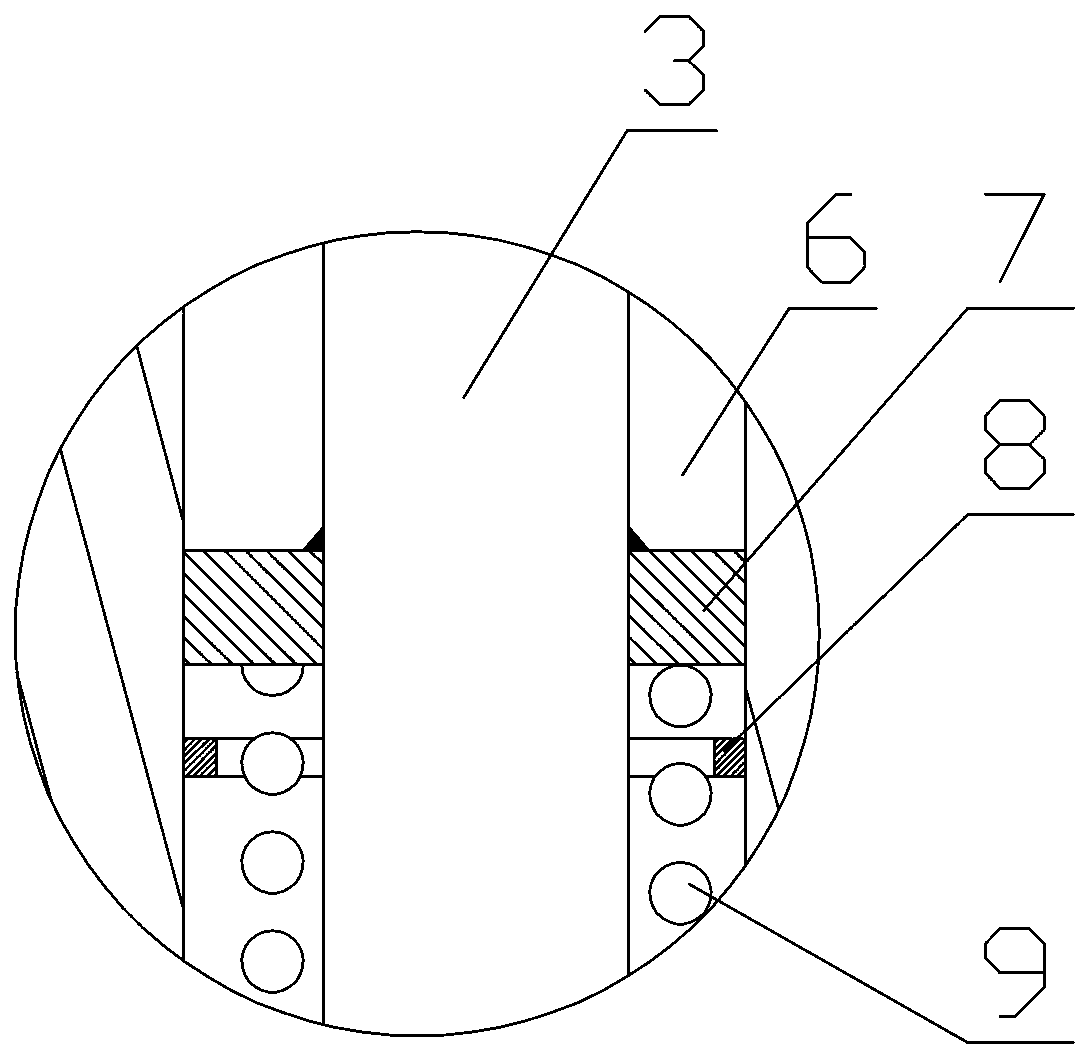

[0013] see Figure 1-Figure 4 , the present invention is an emergency stop trigger device for steel strands to be folded together and formed. It has a base 2, a through hole 6 from top to bottom is arranged in the center of the base, and a spring seat plate is fixed at the lower position in the middle of the through hole. 5. There is a column perforation at the center of the spring seat plate. A column 3 is installed in the hole of the column. A steel strand trigger ring 4 is fixed on the top of the column. A sliding block 7 is fixed on the column. The sliding block It is located in the through hole above the spring seat plate and slides up and down along the inner wall of the through hole. A buffer spring 9 is also set on the column. The upper end of the buffer spring is connected to the bottom of the sliding block, and the lower end of the buffer spring is connected to the The above spring seat plate is fixedly connected; a pressure sensor 8 is also fixed on the inner wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com