Power station gate valve

A technology for gate valves and power stations, applied in sliding valves, valve details, valve devices, etc., can solve problems such as poor sealing, and achieve the effects of improving sealing, increasing sealing, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

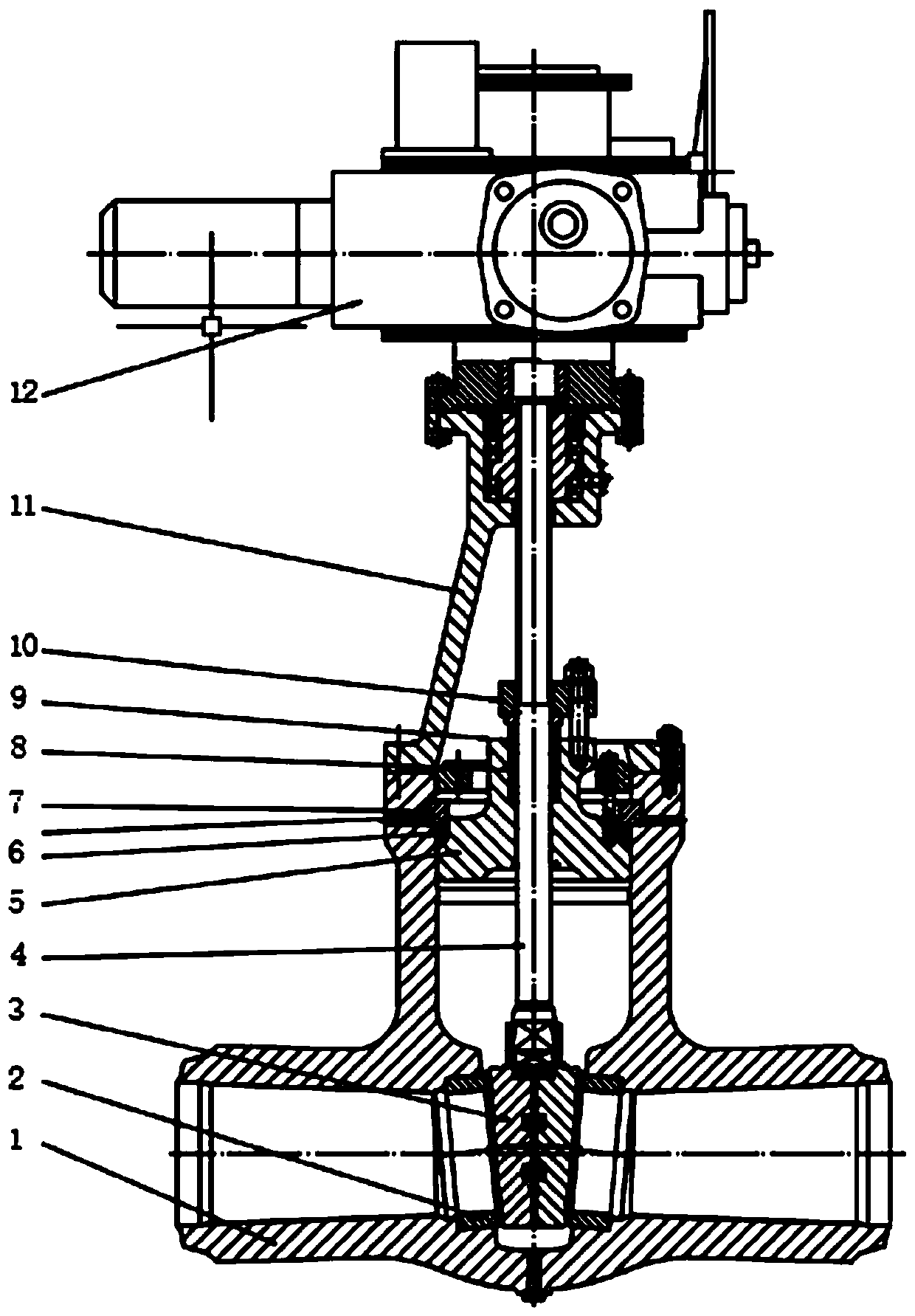

[0020] see figure 1 , the present invention provides the following technical solutions: power station gate valve, including valve body 1, bracket 11 and electric device 12, valve body 1 is a pressure self-sealing structure without bonnet, valve body 1 includes sealing ring 6, four open rings 7 and stuffing box 8. A bonnet 5 is set under the sealing ring 6, and the sealing ring 6 is set between the stuffing box 8 and the valve body 1, and the stuffing pressure plate 10 that engages with the stuffing box 8 is set above the stuffing box 8, and the stuffing box 8 There is a packing gland 9 between the packing plate 10, the stuffing box 8 is provided with a packing hole, and the inner wall of the packing hole is provided with a V-shaped composite packing layer, and the inner bottom of the valve body 1 is symmetrically provided with a valve seat 2, and the valve seat 2 The gate plate 3 used in cooperation with each other is provided at the middle position, the other end of the gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com