Decoration method by splicing socketed lathes

A split-type, decorative surface technology, applied in the direction of covering/lining, building, building structure, etc., can solve the problems of user waste, affecting the surrounding environmental sanitation, and long construction period, so as to improve the ability of curved surface modeling, avoid cumulative assembly errors, The effect of improving the quality of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

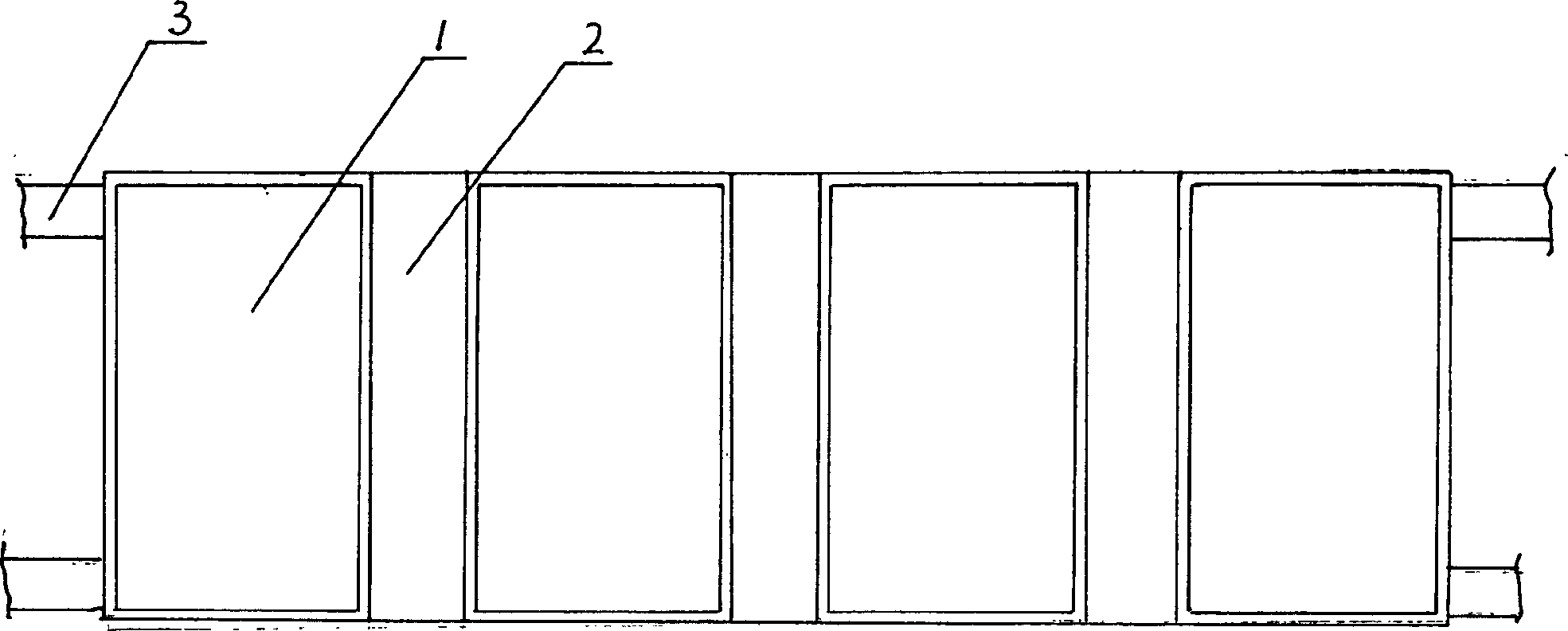

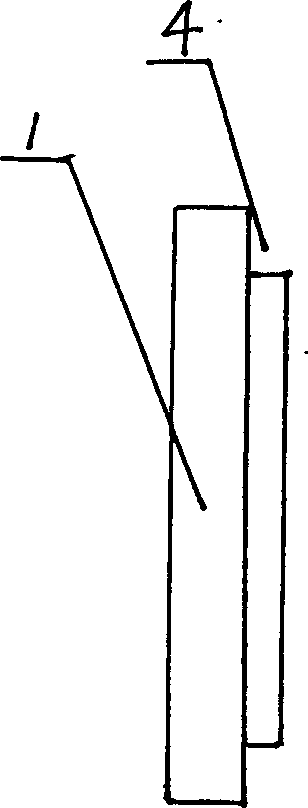

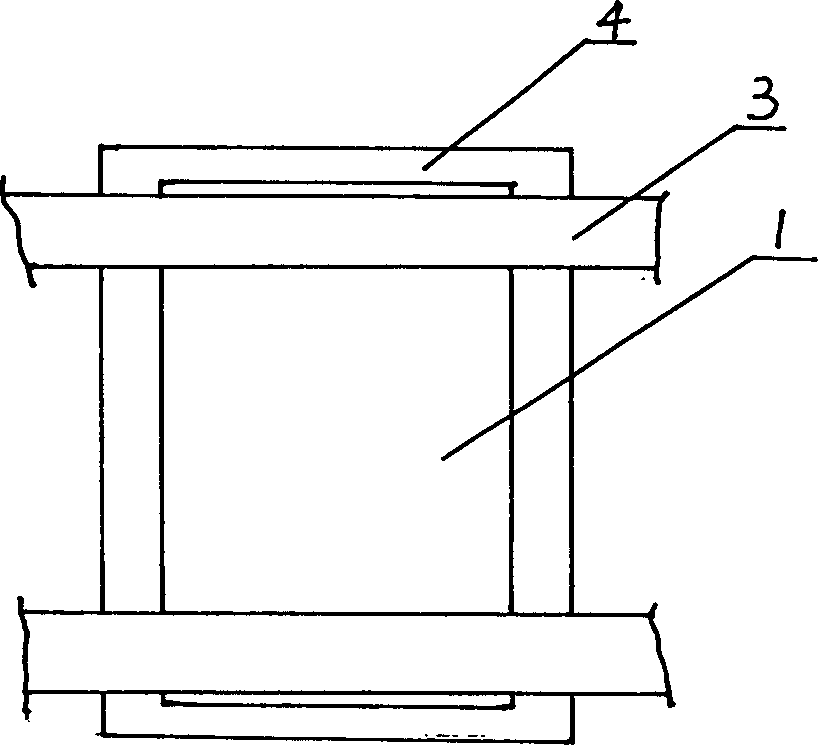

[0020] The technological process of the present invention includes: the manufacture of the standardized decorative module 1, the fabrication and fixing of the decorative surface assembly inserts 2 and the decorative fixing strips 3, the connection and decoration fixation of the standardized decorative module 1, the assembly and embedding of the inserts 2, and sealing treatment.

[0021] The steps of the concrete decoration method of the present invention: the making of A, standardized decoration module 1

[0022] According to the user's requirements, combined with the structure of the house and the decoration and decoration shape, the size of the standardized decoration module is designed, and the standardized decoration module 1 is professionally produced in the factory scale, including surface treatment and engraving, soft packaging, edge sealing, fire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com