Modeling comb

A technology of comb teeth and components, applied in hair combs, clothing, hairdressing equipment, etc., can solve the problems of influence of modeling effect and inconvenient operation, and achieve the effect of enhancing user experience, easy operation, and improving modeling effect and modeling quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

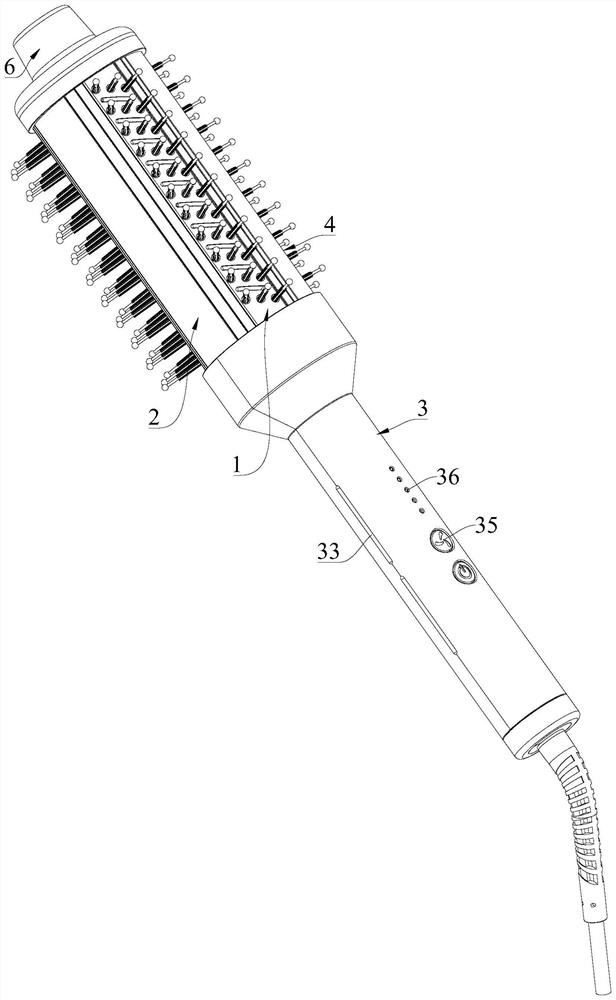

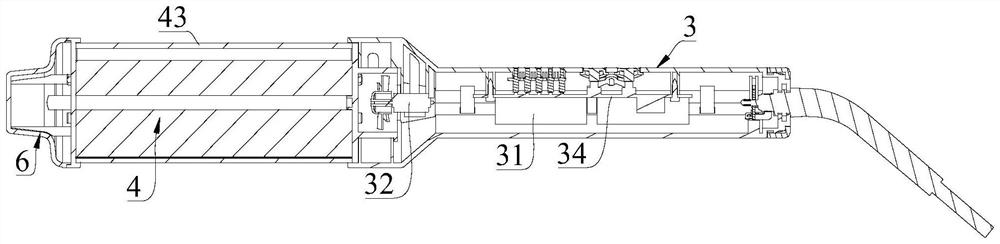

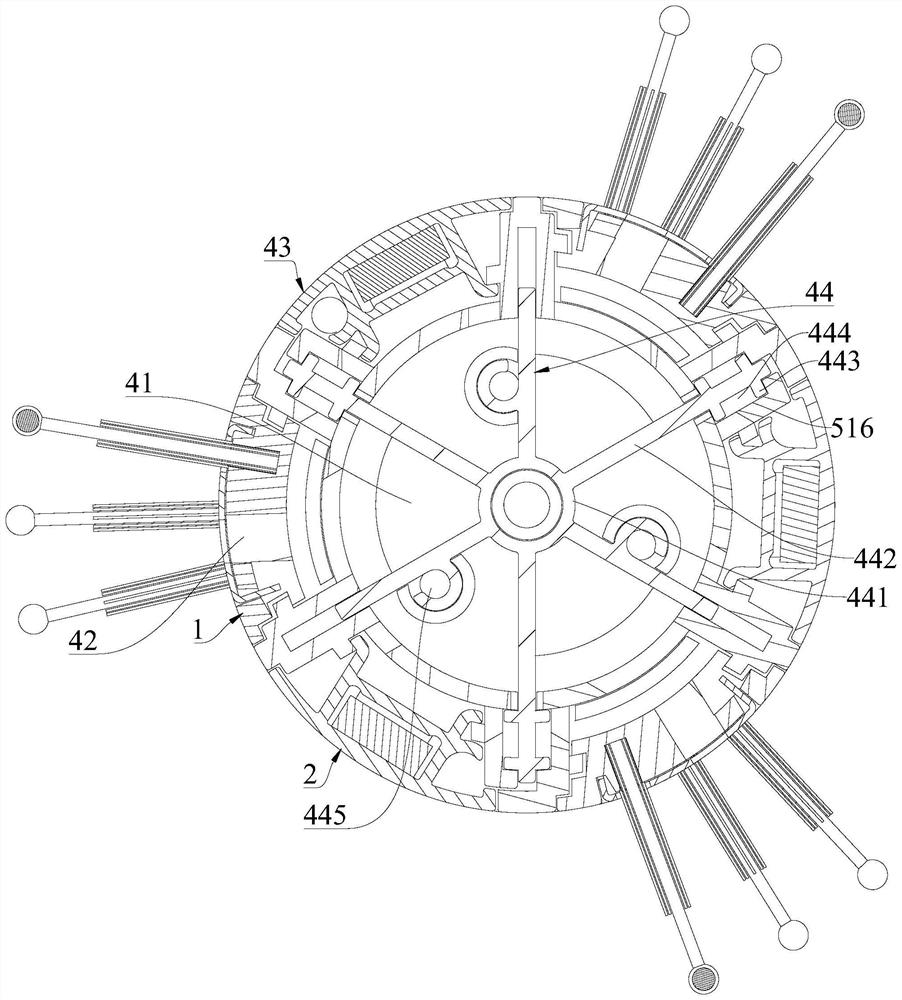

[0040] Please refer to Figure 1 to Figure 4 , Embodiment 1 of the present invention is: a styling comb for hair styling.

[0041] The styling comb includes a cooling comb assembly 1, a heating assembly 2, a connected handle 3 and a cylinder 4, the handle 3 is provided with a first air duct 31 and a fan assembly 32, and the cylinder 4 is provided with a The first air passage 31 communicates with the second air passage 41, the handle 3 is provided with a first air port 33 communicating with the first air passage 31, and the column 4 is provided with a communication with the second air passage 41 The second tuyere 42 is set corresponding to the cooling comb assembly 1, and one cooling comb assembly 1 and one adjacent heating assembly 2 form a unit structure 5, at least The two unit structures 5 enclose the outer ring structure 43 of the cylinder 4 , and in the two adjacent unit structures 5 , the cooling comb assembly 1 and the heating assembly 2 are arranged at intervals.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com