An adjustable component pin bending and shearing integrated device

A component and adjustable technology, applied in the field of adjustable component pin bending and shearing integrated devices, can solve the problems of inability to meet the bending and shearing requirements of different components, inability to achieve continuous operation, and small scope of application, To achieve the effect of simple and fast processing procedures, wide application range and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

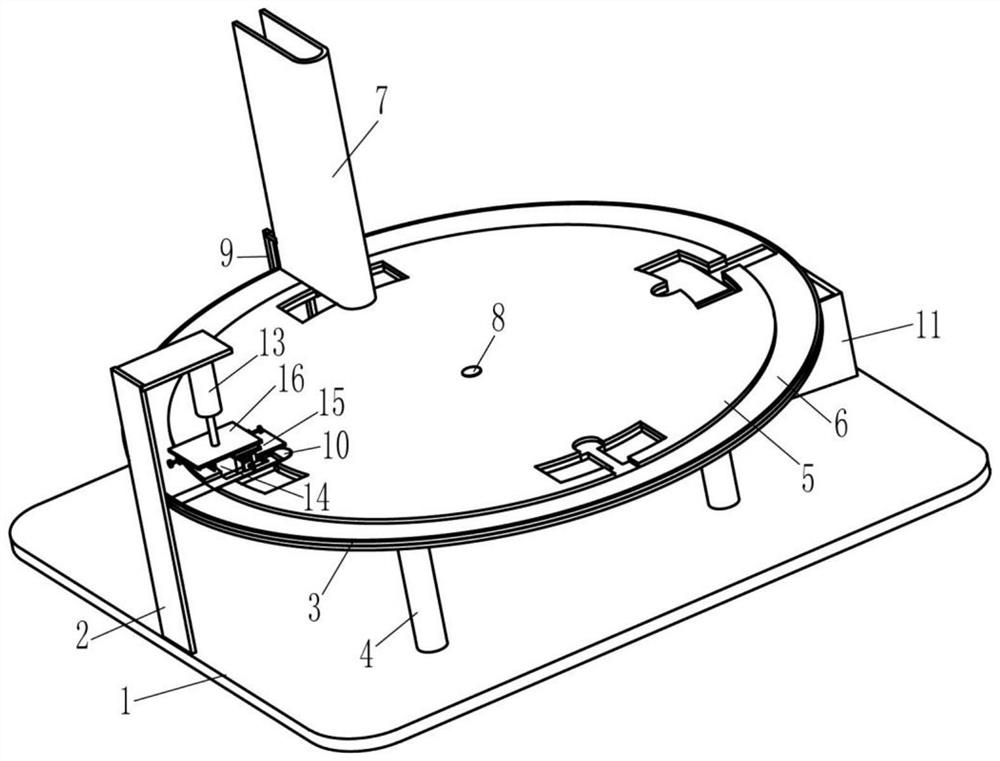

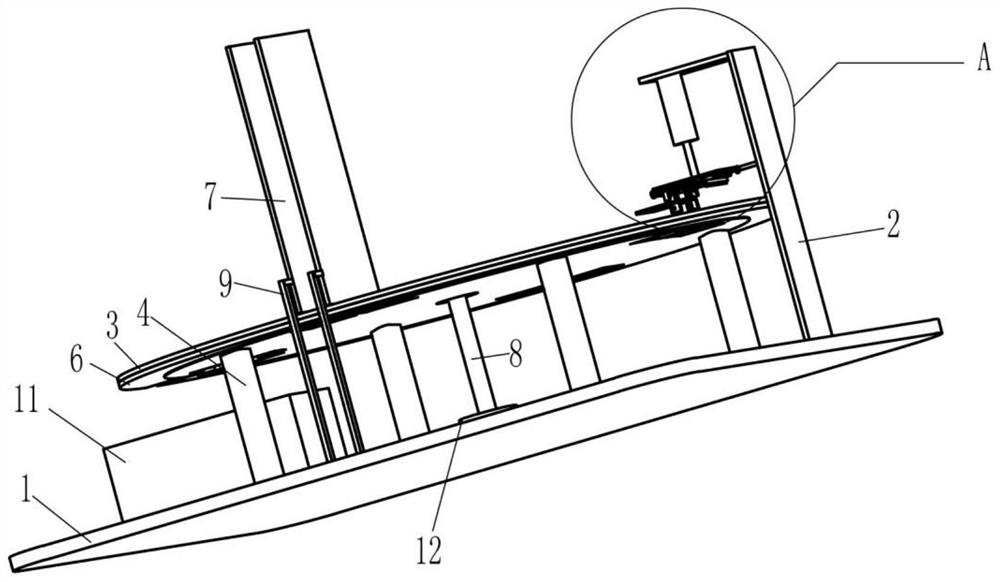

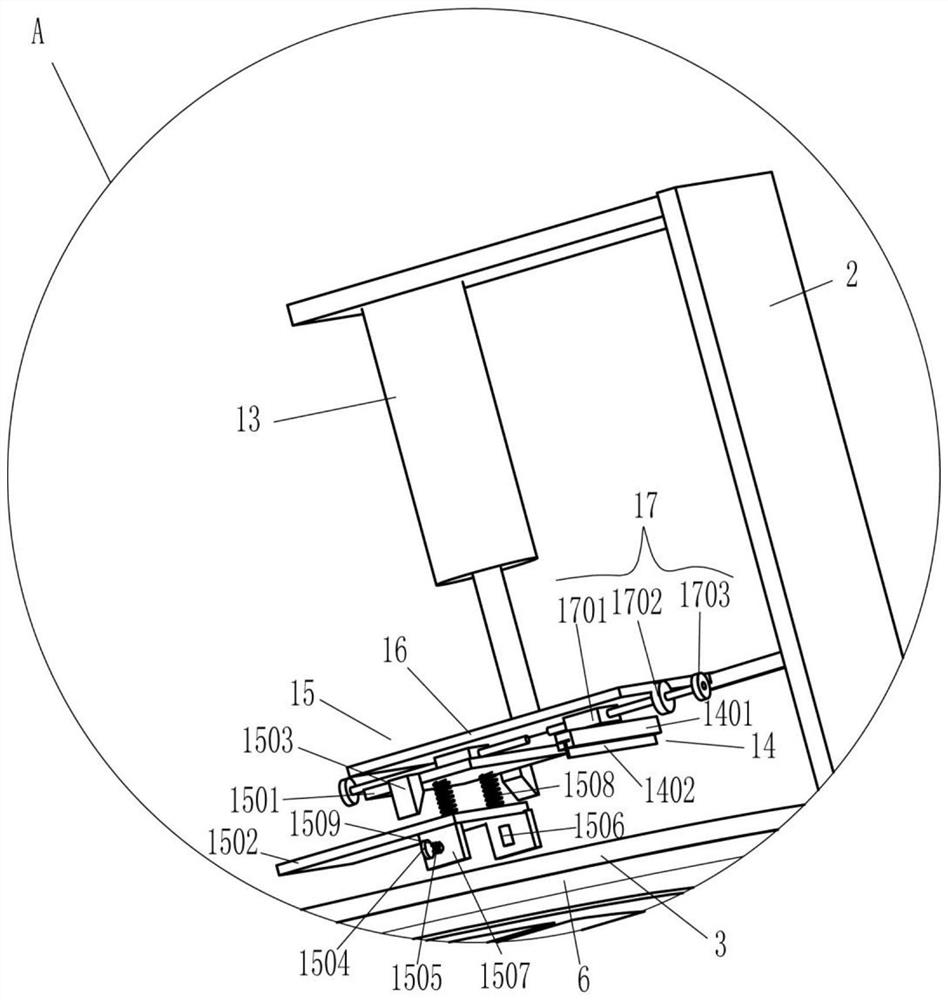

[0024] An adjustable component pin bending and shearing integrated device, such as figure 1 As shown, it includes a base 1, a support arm 2, a limit ring 3, a column 4, a rotating disk 5, a fixed disk 6, a component tank 7, a rotating shaft 8, a support rod 9, a collection tank 11, and a bearing 12. Cylinder 13, shearing part 14 and mounting plate one 16, four uprights 4 are fixedly installed on the base 1, fixed discs 6 are fixedly installed on the upper ends of the four uprights 4, and the fixed discs 6 The upper side is provided with a limit ring 3, and the middle position of the upper side of the base 1 is fixedly equipped with a bearing one 12, and the rotating shaft one 8 is connected through an interference in the bearing one 12, and a middle position of the fixed disk 6 is provided with a The upper end of the through hole and the rotating shaft 8 passing through the through hole is provided with a rotating disk 5, the rotating disk 5 is located above the fixed disk 6, ...

Embodiment 2

[0029] An adjustable component pin bending and shearing integrated device, such as figure 1As shown, it includes a base 1, a support arm 2, a limit ring 3, a column 4, a rotating disk 5, a fixed disk 6, components 10, a tank 7, a rotating shaft 8, a support rod 9, a collection tank 11, Bearing one 12, cylinder 13, shearing part 14 and mounting plate one 16, described base 1 is fixedly installed with 4 uprights 4, and the upper end of 4 described uprights 4 is fixedly installed with fixed plate 6, and described fixed plate The upper side of 6 is provided with a limit ring 3, and the middle position of the upper side of the base 1 is fixedly equipped with a bearing 12, and the rotating shaft 8 is connected through the interference in the bearing 12, and the middle position of the fixed disk 6 A through hole is provided and the upper end of the rotating shaft 8 passing through the through hole is provided with a rotating disk 5, the rotating disk 5 is located above the fixed disk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com