Multiple grinding and squeezing equipment for tea oil production

A multiple, camellia oil technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of wasting camellia oil, economic losses, etc., and achieve the effect of improving work efficiency and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

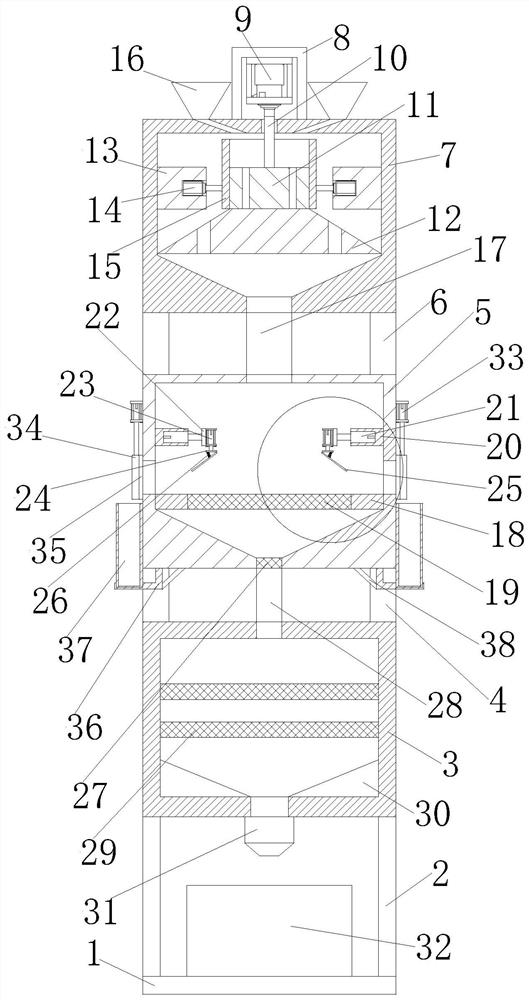

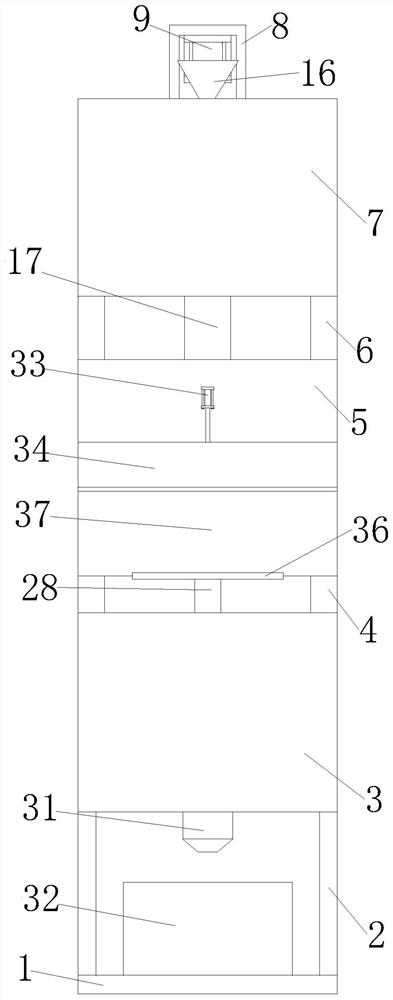

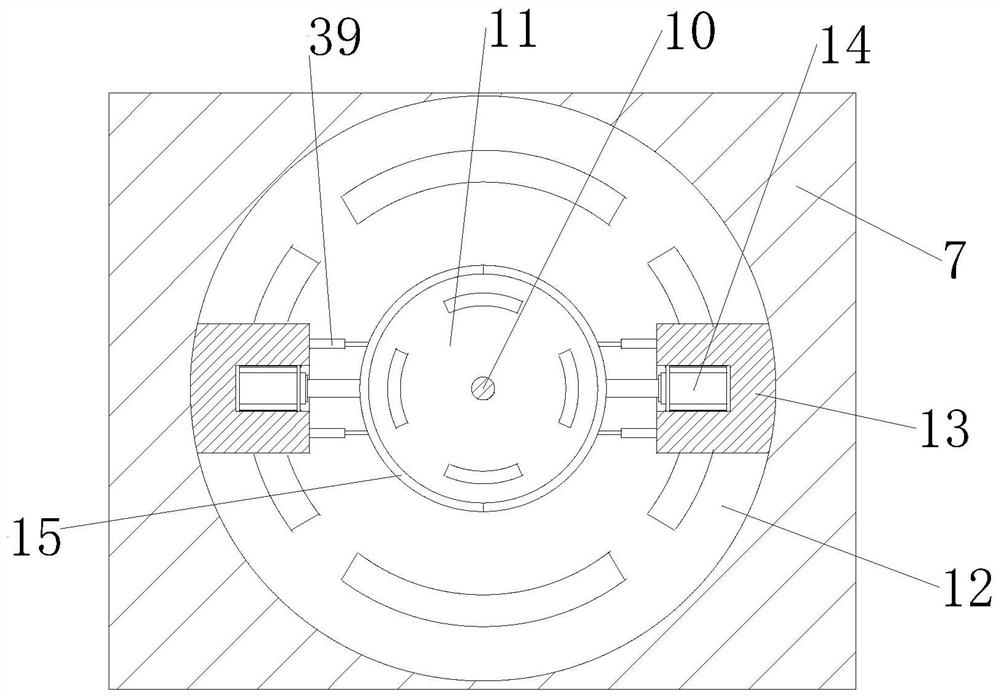

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-5Shown, a kind of camellia oil production is used multiple milling press equipment, comprises installation plate 1, and described installation plate 1 is installed with the first support leg 2 of two pairs of identical structures, and two pairs of described first support legs 2 are installed with Filter box 3, two pairs of second support legs 4 with the same structure are installed on the filter box 3, press boxes 5 are installed on the two pairs of the second support legs 4, two pairs of structures are installed on the press box 5 The same third support leg 6, two pairs of the third support legs 6 are equipped with grinding boxes 7, the pressing box 5 is equipped with a pressing structure, and the grinding box 7 is equipped with multiple grinding structures; the multiple Grinding structure, including: mounting frame 8, rotating motor 9, rotating rod 10, grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com