Mounting structure of assembled unit keel partition wall

An installation structure and assembly technology, applied in the direction of walls, building components, building structures, etc., to achieve the effect of easy positioning and installation, enhanced overall strength and stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

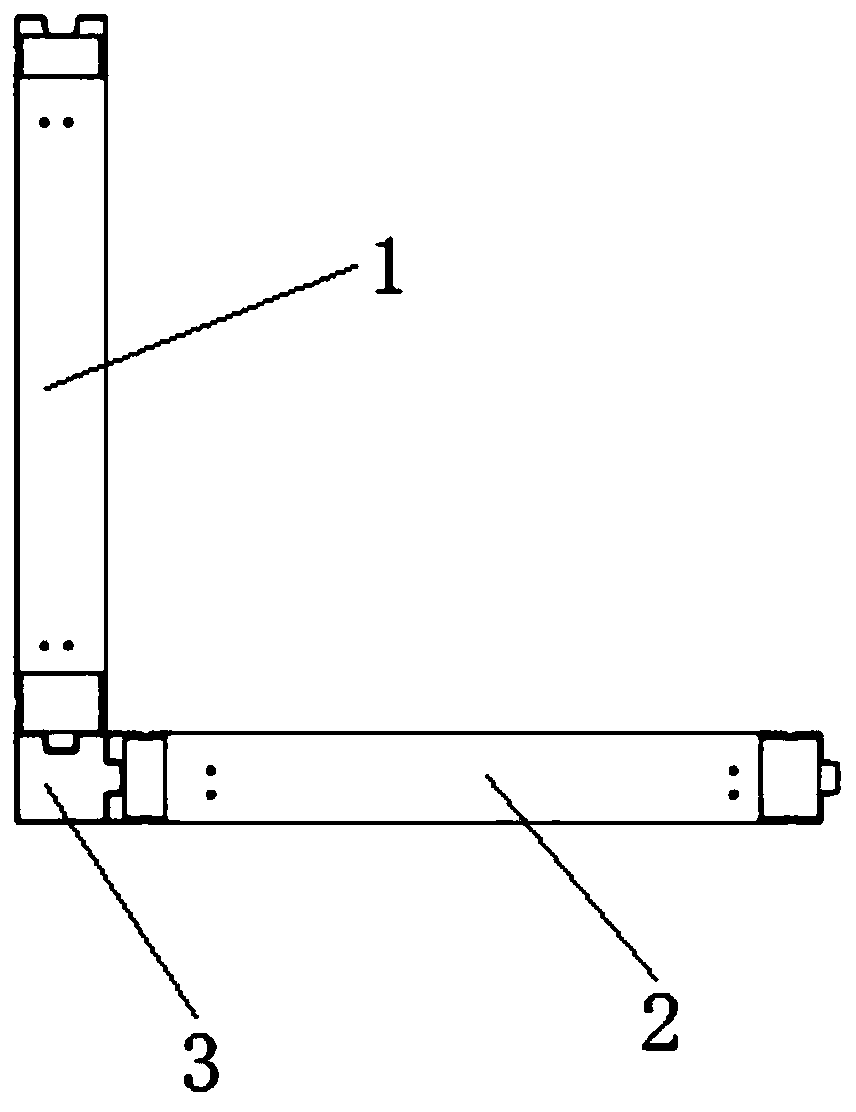

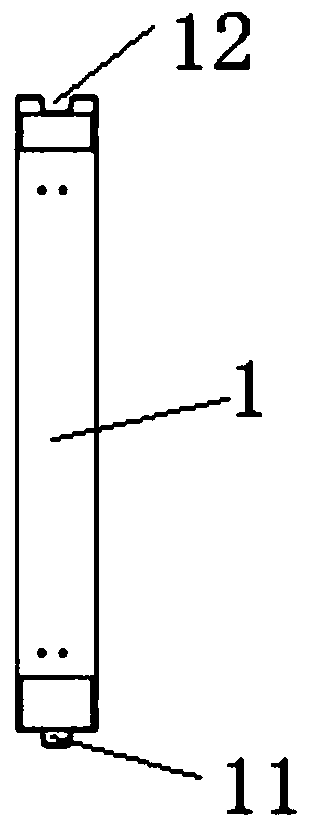

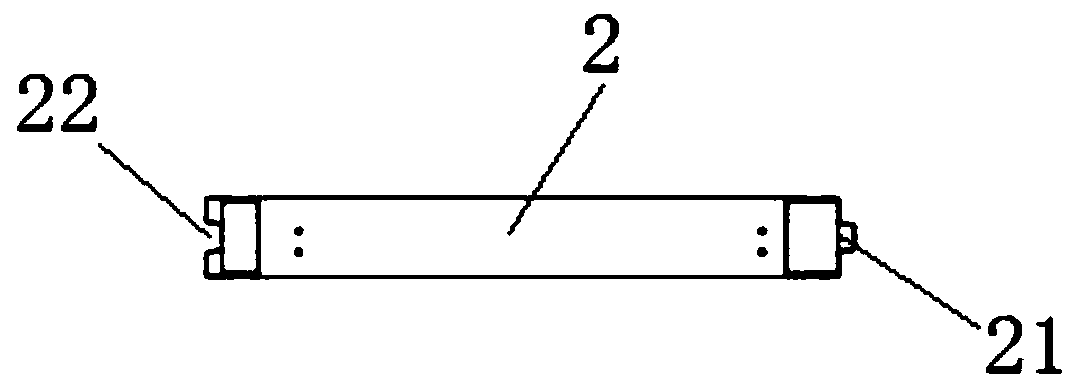

[0030] see Figure 1 to Figure 5 , the figure shows the installation structure of a prefabricated unit keel partition wall provided by Embodiment 1 of the present invention, which includes: a first connecting keel (1), and a first connecting protrusion (11) is provided in the middle of one end ), the middle position of the other end is provided with the first connecting groove (12); the second connecting keel (2), the middle position of one end is provided with the second connecting protrusion (21), and the middle position of the other end is provided with the second Two connection grooves (22); male and female corner connectors (3), which include a right-angled side (31), a first connecting side (32) and a second connecting side (33), on the first connecting side (32) A third connection groove (321) is provided, and a third connection protrusion (331) is provided on the second connection side (33); the third connection groove (321) is connected with the first connection protr...

Embodiment 2

[0037] see Figure 2 to Figure 5 , the figure shows the installation structure of a prefabricated unit keel partition wall provided by Embodiment 2 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The shape and size of the first connection protrusion (11) and the second connection protrusion (21) are the same; the shape and size of the first connection groove (12) and the second connection groove (22) The same size; the third connection groove (321) matches the shape and size of the first connection protrusion (11); the third connection protrusion (331) matches the second connection groove ( 22) to match the shape and size. Through the setting of the above structure, the first connecting keel 1 and the second connecting keel 2 have the same structure, which is convenient for mass production, reduces production difficulty and production cost; at the same time, the first co...

Embodiment 3

[0039] see Figure 4-5 , the figure shows the installation structure of a prefabricated unit keel partition wall provided by Embodiment 3 of the present invention. This embodiment further makes the following technical solutions as improvements on the basis of the above-mentioned embodiments: The opening size of the third connection groove (321) is larger than the bottom size; the top size of the third connection protrusion (331) is smaller than the bottom size. Through the setting of the above structure, it is convenient to clamp and improve the installation efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com