Gis

A technology of arm box and moving contact is applied in GIS. It can solve the problems of aging insulation and unreliability of insulation sleeves and insulation pads, and achieve the effect of being conducive to miniaturization, ensuring stability, and ensuring insulation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

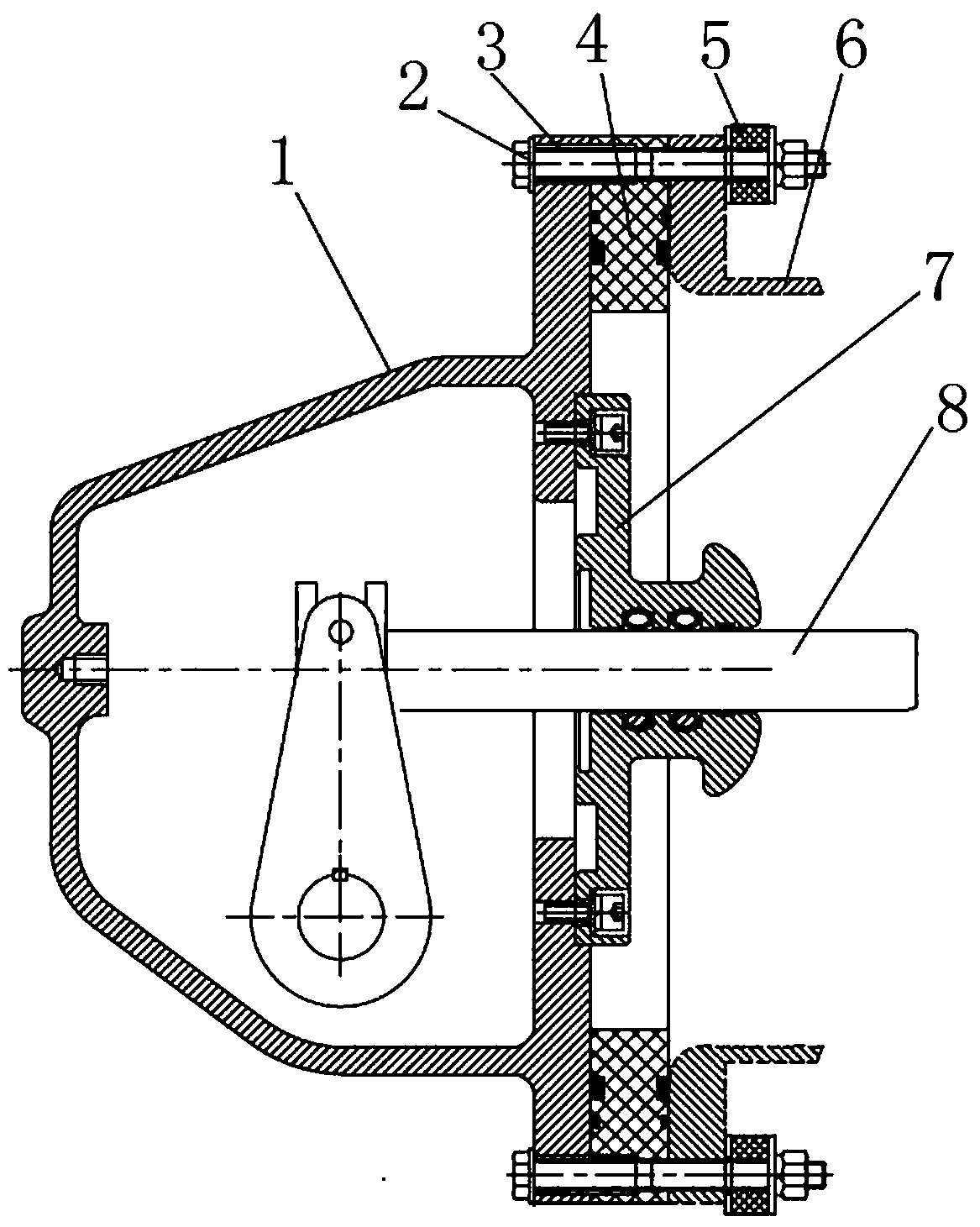

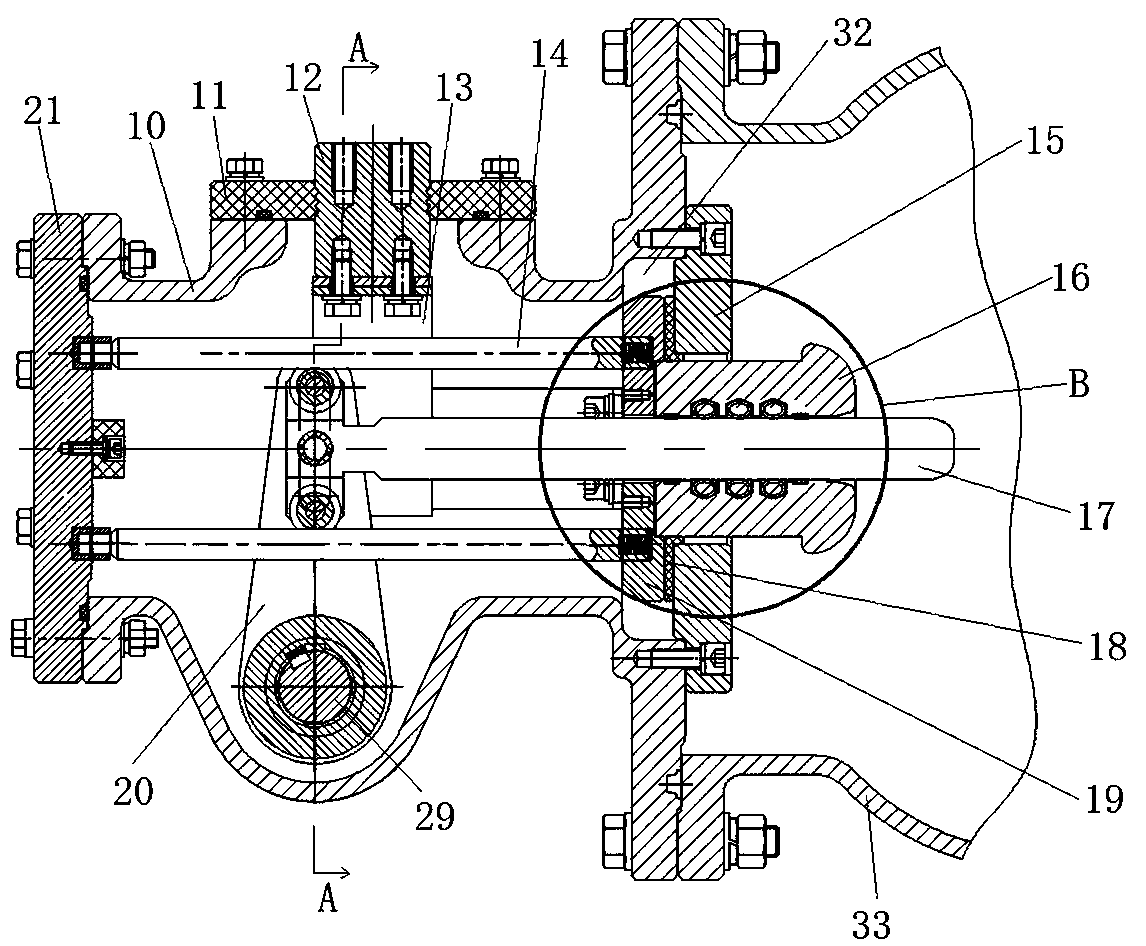

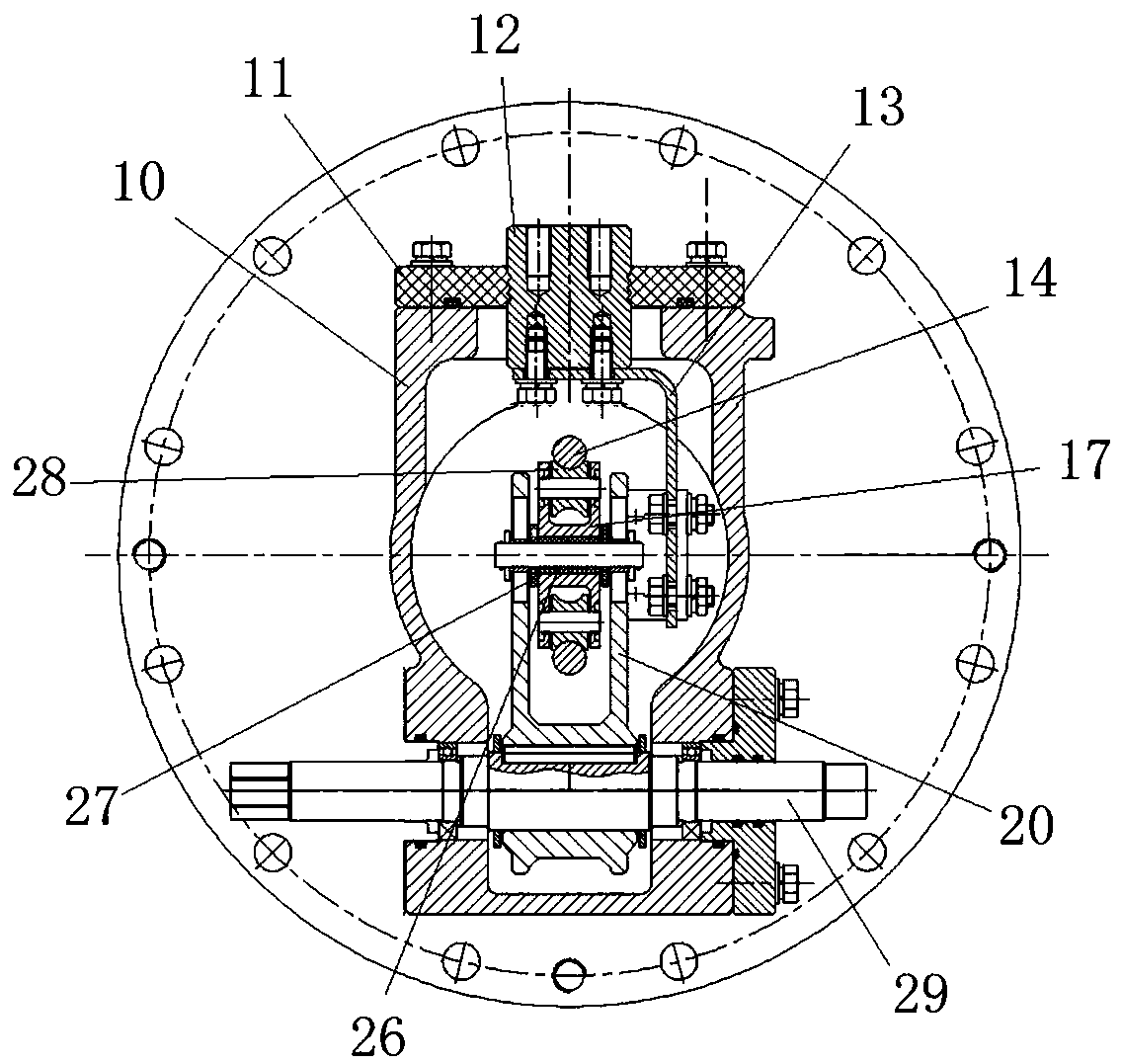

[0041] Such as figure 2 and image 3 As shown, the GIS includes a GIS cylinder 33 and a crank box 10, the crank box 10 has a cylinder connection end, and the cylinder connection end is fixedly connected to the GIS cylinder 33, and the cylinder connection end is provided with a flange connection plate 15, A movable contact seat is fixedly mounted on the flange connection plate 15, and a movable contact 17 is guided and installed in the movable contact seat, and the movable contact 17 is in contact with the static contact in the GIS barrel 33 to realize grounding. A crank arm 20 is provided in the crank arm box, and a drive shaft 29 is installed on the crank arm box 10 for rotation. When the crank arm 20 is driven to swing, the movable contact 17 is driven by the crank arm 20 to move, so as to realize the insertion and separation of the movable contact 17 and the static contact.

[0042] Such as figure 2 and Figure 4 As shown, the flange connection plate 15 is a metal pla...

Embodiment 2

[0058] The difference from Embodiment 1 is that the flange connection plate is an insulating seat, no cylinder perforation is provided on the flange connection plate, and the moving contact seat only includes a column guide body, which is embedded in the flange connection plate.

Embodiment 3

[0060] The difference from Embodiment 1 is that the connection plate body and the columnar guide body are integrally structured. At this time, the hole diameter of the column body on the flange connection plate is required to be larger than the maximum diameter of the columnar guide body, so that the columnar guide body can pass through the flange. Lan connection plate. In other embodiments, the connection plate body and the columnar guide body can be arranged separately, but the fixed connection is realized by welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com