A thermal printer segmentation printing method, device and thermal printer

A technology of thermal printers and jokes, applied in printing devices, printing, etc., can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

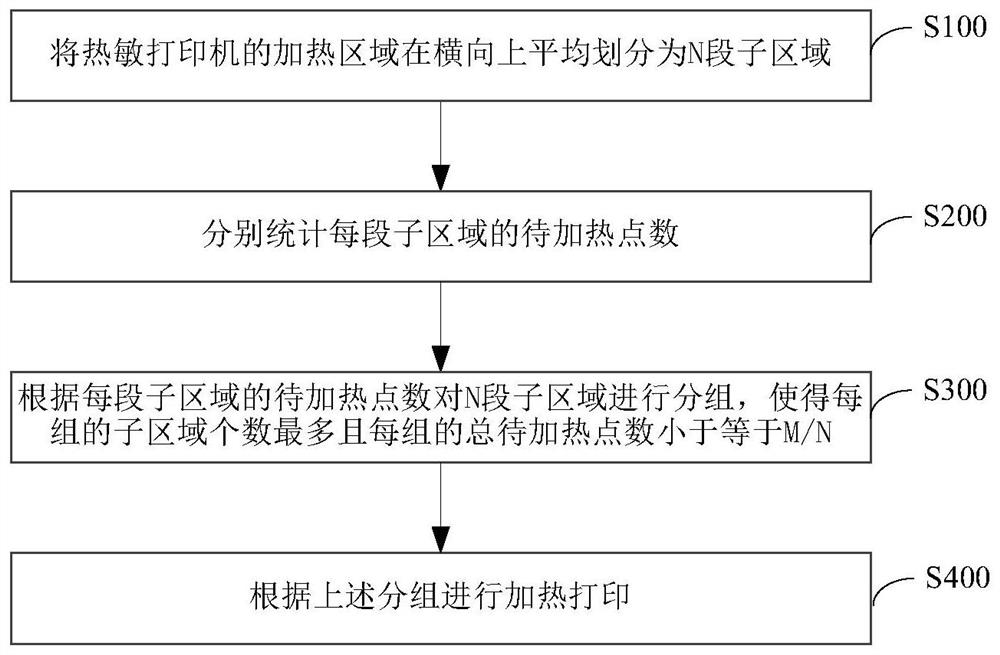

[0043] This embodiment provides a thermal printer segmentation printing method, such as figure 1 shown, including the following steps:

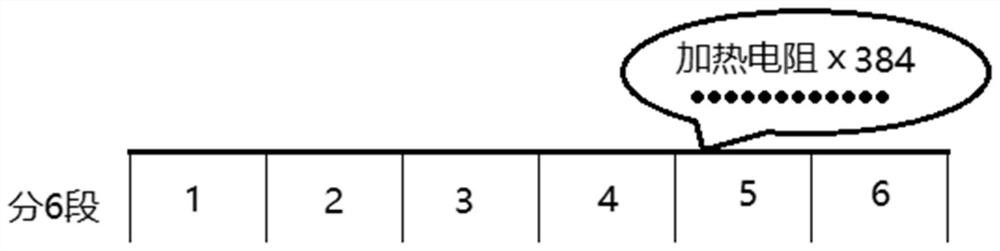

[0044] Step S100, dividing the heating area of the thermal printer into N sections of sub-areas in the horizontal direction, and the heating area includes M heating points, so each sub-area includes M / N heating points;

[0045] Step S200, respectively counting the number of points to be heated in each sub-region, and the number of points to be heated in each sub-region is less than or equal to M / N;

[0046] Step S300, grouping N sections of sub-areas according to the number of points to be heated in each sub-area, so that the number of sub-areas in each group is the largest and the total number of points to be heated in each group P≤M / N;

[0047] Step S400, perform thermal printing according to the above grouping.

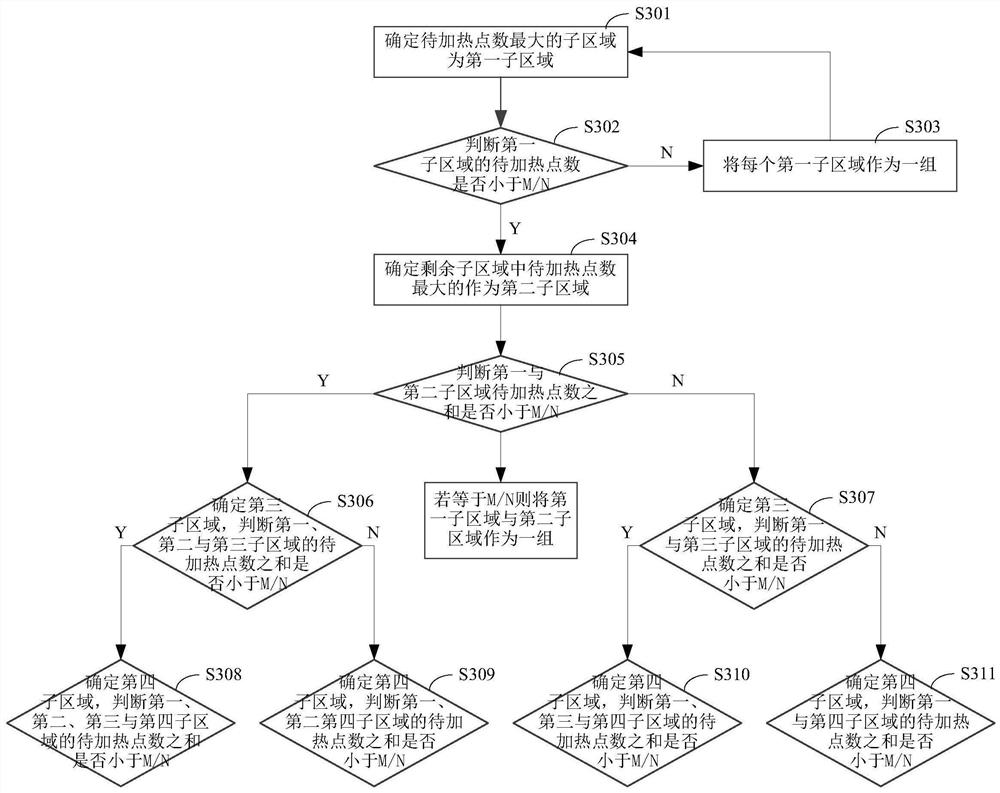

[0048] Among them, such as figure 2 As shown, step S300 specifically includes:

[0049] Step S301, determining the sub-ar...

example 1

[0063] After the printer receives a row of data to be printed, it counts the number of points to be heated for each sub-region according to the row of data. It can be understood that the number of points to be heated for each sub-region does not exceed 64 points. Such as Figure 4 As shown, the six sub-regions are respectively marked as A1-A6, and the statistical results are: 64 points, 48 points, 10 points, 15 points, 20 points, and 30 points.

[0064] but

[0065] Step S301, determining that the sub-area with the largest number of points to be heated is the first sub-area, that is, A1 is the first sub-area;

[0066] Step S302, judging whether the number 64 of points to be heated in the first sub-area A1 is less than 64, if the result is no, execute step S303;

[0067] Step S303, take each first sub-area as a group, that is, the first sub-area A1 as a group, return to step S301, determine the sub-area with the largest number of points to be heated as the first sub-area, ...

example 2

[0075] After the printer receives a row of data to be printed, it counts the number of points to be heated for each sub-region according to the row of data. It can be understood that the number of points to be heated for each sub-region does not exceed 64 points. Such as Figure 5 As shown, the six sub-regions are recorded as B1-B6 respectively, and the statistical results are: 64 points, 3 points, 64 points, 5 points, 64 points, and 29 points. but

[0076] Step S301, determining that the sub-area with the largest number of points to be heated is the first sub-area, that is, B1, B3, and B5 are all the first sub-areas;

[0077] Step S302, judging whether the number 64 of points to be heated in the first sub-regions B1, B3, B5 is less than 64, if the result is no, execute step S303;

[0078] Step S303, each of the first sub-regions as a group, that is, each of the first sub-regions B1, B3, B5 as a group, return to step S301, determine the sub-region with the largest number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com