A 3D printing batch control method considering printing quality

A technology of 3D printing and control methods, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problems of 3D printer usage efficiency, low system productivity, 3D printing manufacturing system optimization problems, single task distribution and printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

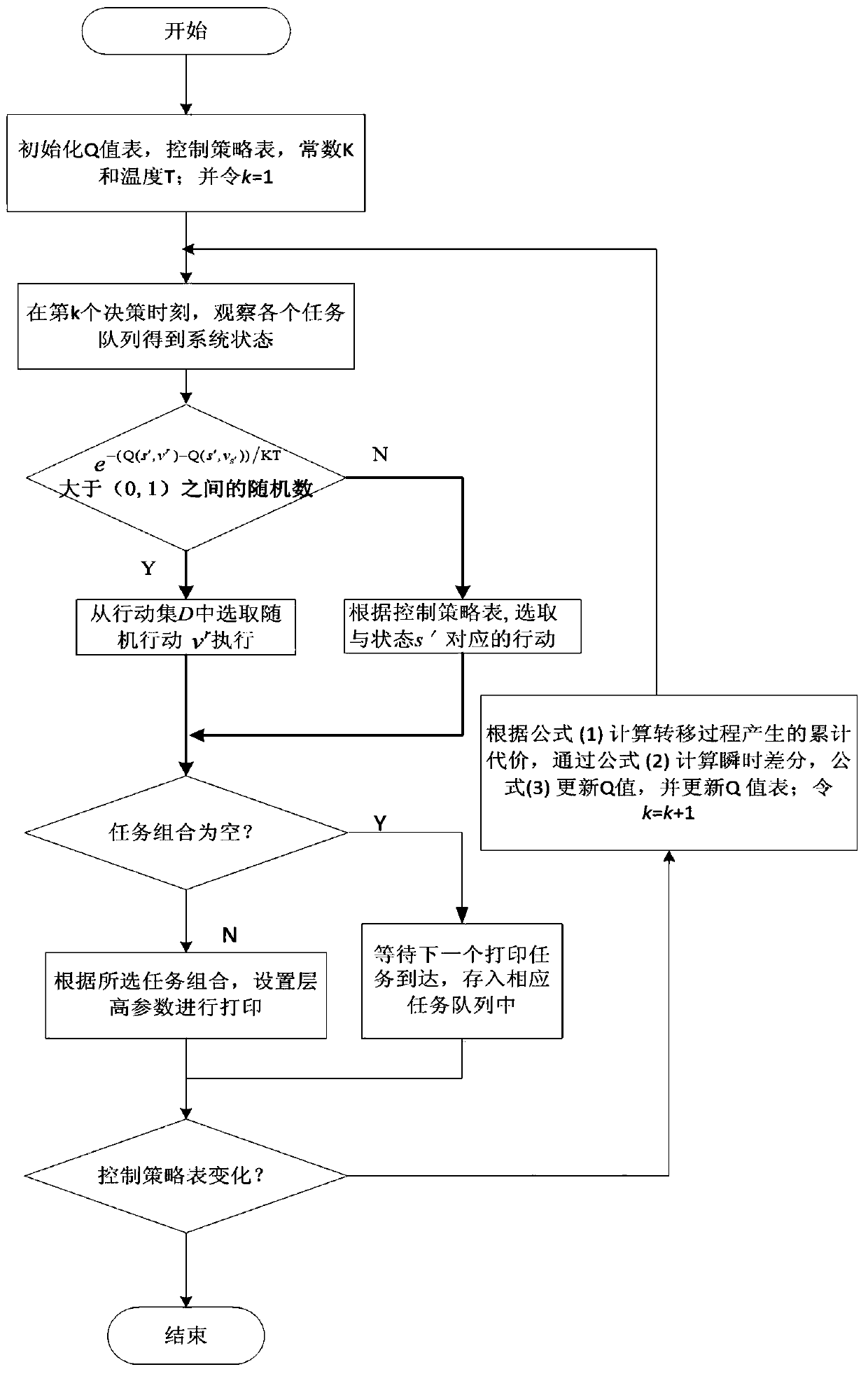

Method used

Image

Examples

Embodiment Construction

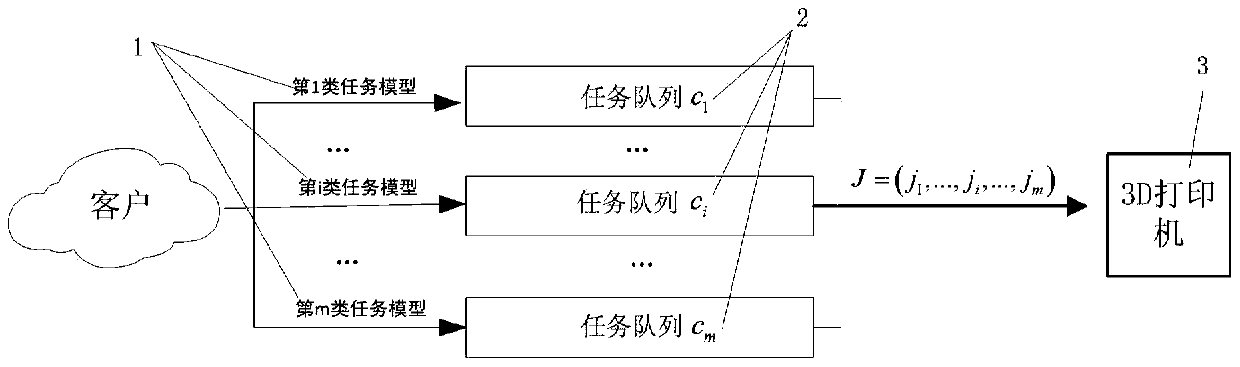

[0039] In this example, if figure 2 As shown, a 3D printing batch control method considering printing quality is applied to a 3D printing manufacturing system composed of m printing task models 1, m task queues 2, and 3D printers with a capacity of N, and The types of consumables for each printing task model are the same; the capacity of the 3D printer group 3 is determined by the size of the printing platform.

[0040] Record the bottom surface size of the i-th printing task model as o i ;The size of the bottom surface of the print task model is determined by the size of the smallest enclosing rectangle of the model's horizontal projection shape; set the queue capacity of the i-th task queue as C i , and the i-th printing task model is stored in the i-th task queue;

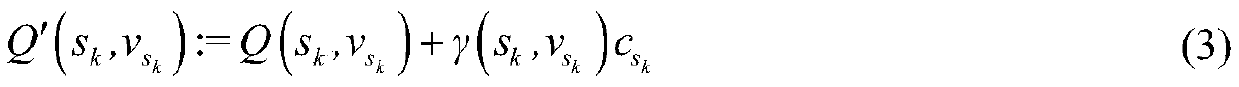

[0041] Suppose the length c of the i-th task queue i is the state of the i-th task queue, then let the state c of the i-th task queue i Belonging to the state space Φ i ={0,1,2,...,C i}, i=1,2,...,m; then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com