Flame-retardant and environment-friendly carbon fiber

A technology of carbon fiber and carbon fiber cotton, which is applied in the fields of fiber chemical characteristics, manufacture of fire-resistant and flame-retardant filaments, film/sheet-like adhesives, etc. Excellent environmental protection and flame retardant properties, good heat insulation and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

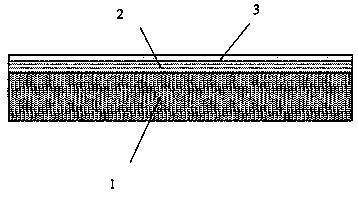

[0021] A flame-retardant carbon fiber cotton veneer, the flame-retardant carbon fiber cotton veneer has a two-layer structure, one of which is a flame-retardant carbon fiber cotton layer 1, and the other layer is a hot-melt adhesive layer, and the hot-melt adhesive layer is coated On the flame-retardant carbon fiber cotton layer 1, the hot melt adhesive layer includes a fiber transition layer 3 and a surface coating 2, the fiber transition layer 3 is formed by mixing hot melt adhesive and fiber cotton, and the surface coating 2 Inside is a single hot melt adhesive. The thickness of the hot-melt adhesive layer is 0.2mm, and the thickness of the fiber transition layer 3 is 0.1-0.12mm, which can prevent the bonding force between the adhesive layer and the fiber cotton from being insufficient, resulting in the high-temperature attachment of the carbon fiber veneer. When there is a problem of fiber cotton falling off, at the same time prevent the amount of glue on the surface coati...

Embodiment 2

[0027] A flame-retardant carbon fiber cotton veneer, the flame-retardant carbon fiber cotton veneer has a two-layer structure, one of which is a flame-retardant carbon fiber cotton layer 1, and the other layer is a hot-melt adhesive layer, and the hot-melt adhesive layer is coated On the flame-retardant carbon fiber cotton layer 1, the hot melt adhesive layer includes a fiber transition layer 3 and a surface coating 2, the fiber transition layer 3 is formed by mixing hot melt adhesive and fiber cotton, and the surface coating 2 Inside is a single hot melt adhesive. The total thickness of the hot-melt adhesive layer is 0.3mm, and the thickness of the fiber transition layer 3 is 0.1-0.2mm, which can prevent the insufficient bonding force between the adhesive layer and the fiber cotton, resulting in the high temperature attachment of the carbon fiber veneer. When there is a problem of fiber cotton falling off, at the same time prevent the amount of glue on the surface coating 2 f...

Embodiment 3

[0033] A flame-retardant carbon fiber cotton veneer, the flame-retardant carbon fiber cotton veneer has a two-layer structure, one of which is a flame-retardant carbon fiber cotton layer 1, and the other layer is a hot-melt adhesive layer, and the hot-melt adhesive layer is coated On the flame-retardant carbon fiber cotton layer 1, the hot melt adhesive layer includes a fiber transition layer 3 and a surface coating 2, the fiber transition layer 3 is formed by mixing hot melt adhesive and fiber cotton, and the surface coating 2 Inside is a single hot melt adhesive. The thickness of the hot-melt adhesive layer is 0.5mm, and the thickness of the fiber transition layer 3 is 0.2-0.3mm, which can prevent the insufficient bonding force between the adhesive layer and the fiber cotton, resulting in the carbon fiber veneer being pasted at high temperature. When there is a problem of fiber cotton falling off, at the same time prevent the amount of glue on the surface coating 2 from bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com