Double-high-voltage inorganic super capacitor

A supercapacitor, dual high-voltage technology, applied in the direction of hybrid box/shell/package, etc., can solve the problems of high internal resistance, poor environmental tolerance, poor pressure tolerance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

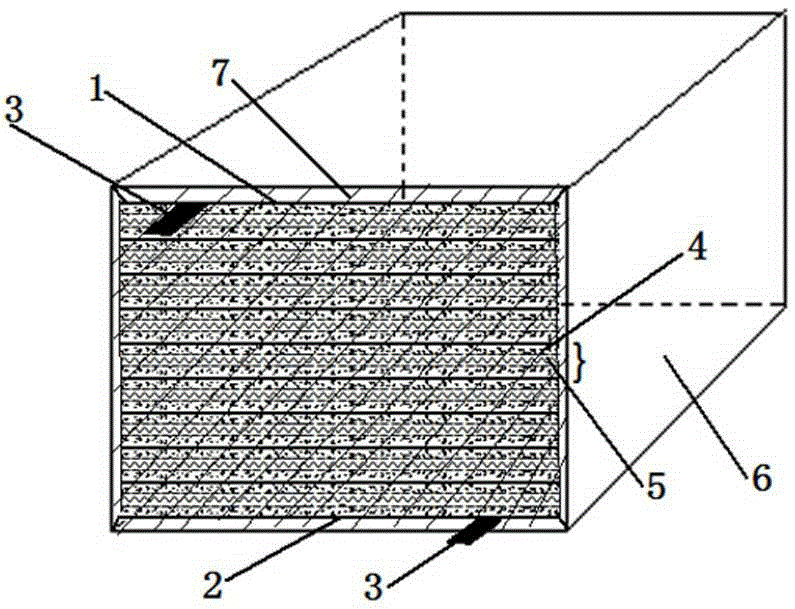

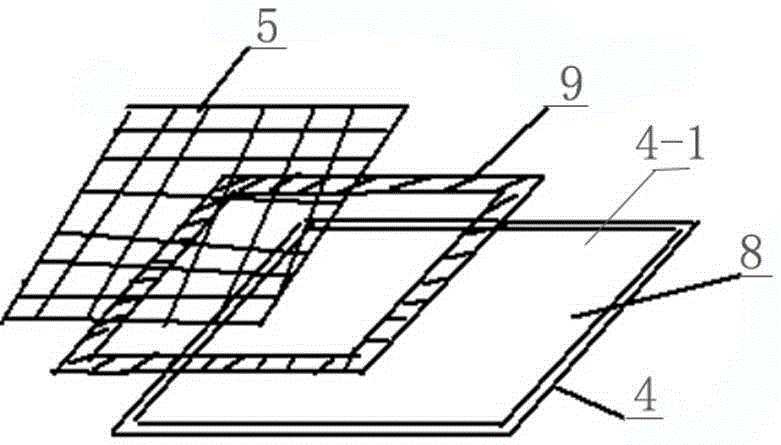

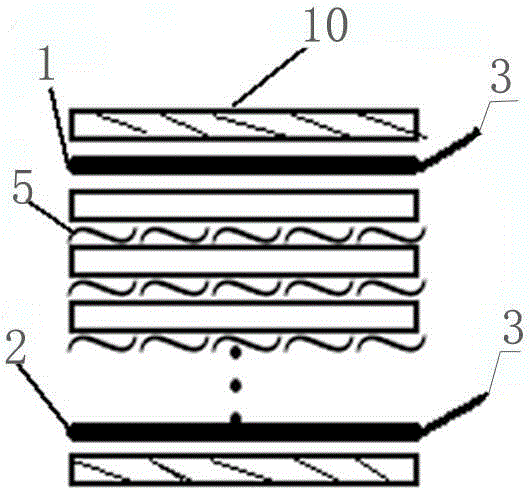

Embodiment 1

[0030] Embodiment 1: The dual high-voltage inorganic supercapacitor of this example has two electrode plates, which are respectively positive electrode plate 1 and negative electrode plate 2, and each of the two electrode plates extends a tab 3 for external power supply. There are at least 30 or more capacitor monomers between the two electrode plates, that is, the active material sheet 4. The active material sheet 4 is composed of the current collector sheet 4-1 and the activated carbon powder 8 coated on it. After the material sheet 4 is scraped, an insulating frame 9 is placed on it, and the adjacent capacitor cells are separated by a diaphragm 5, and then the capacitor cells stacked in series are put into a package casing 6 of the same size, and the stacking sequence is in accordance with the epoxy resin Strip 10, positive electrode plate 1, capacitor monomer, negative electrode plate 2, epoxy resin strip 10, use 5-13 T pressure to press the cover into the package shell 6 a...

Embodiment 2

[0031] Embodiment 2: In the dual high-voltage inorganic supercapacitor of this example, 4 active material sheets are 90 sheets, and 4 electrode sheets are taken. The stacking order is to take electrode sheet A, 30 active material sheets, and take electrode sheet B, 30 sheets. 1 sheet of active material, take electrode plate C, 30 active material sheets, take electrode plate D, and the rest of the operations are the same as in Example 1.

[0032] When the external power supply is connected, the tab of the electrode plate A and the tab of the electrode plate C are welded together to form a new positive electrode, and the tab of the electrode plate D and the tab of the electrode plate B are welded together to form a new positive electrode. of the negative electrode. After assembly, it is a 24 V, 18 mΩ, 45 F high-voltage supercapacitor, which is mainly used for starting heavy trucks. The maximum voltage for short-term overcharge is 28 V, and it can charge and discharge stably at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com