Cusp field plasma thruster capable of improving thrust resolution ratio and working medium utilization rate

A plasma and resolution technology, applied in the direction of using plasma, thrust reversers, machines/engines, etc., can solve the problems such as the decline of discharge performance such as thruster discharge efficiency, and the inability to adjust resolution to meet drag-free control, etc. The effect of working medium utilization rate and discharge efficiency, improving working medium utilization rate and improving thrust resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

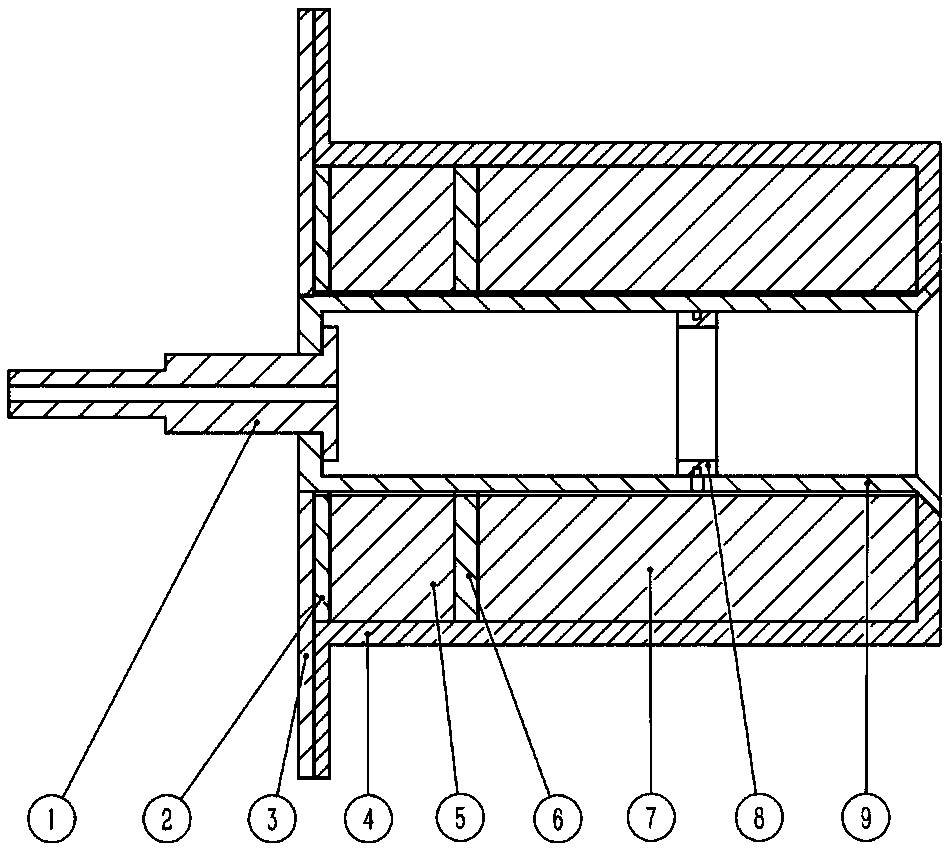

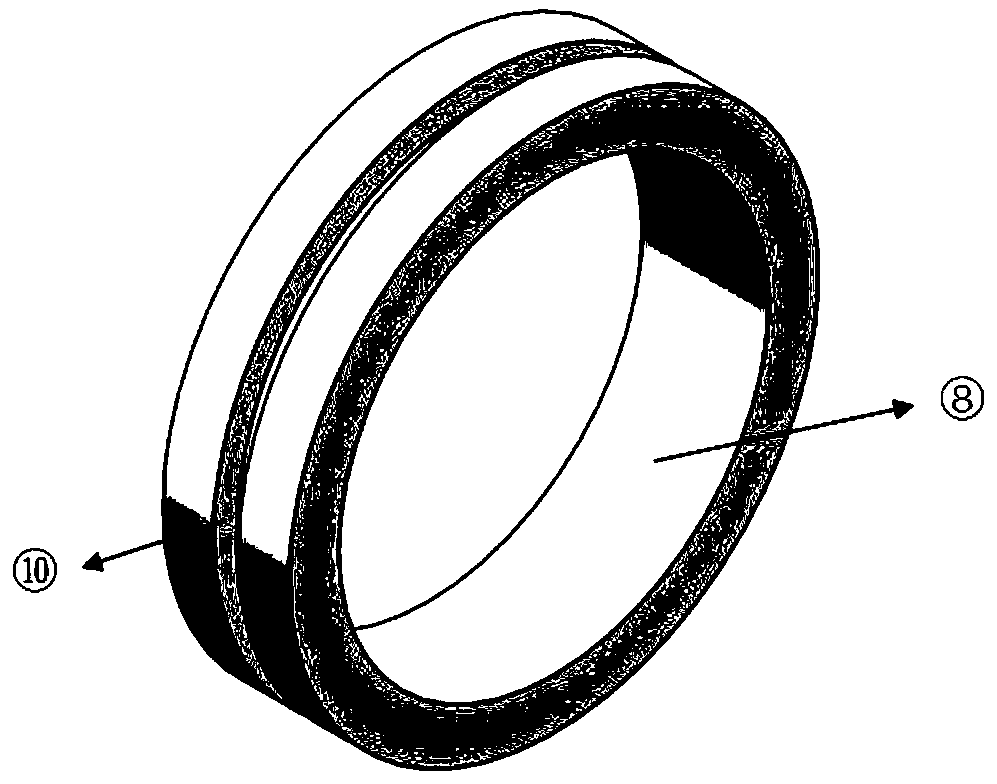

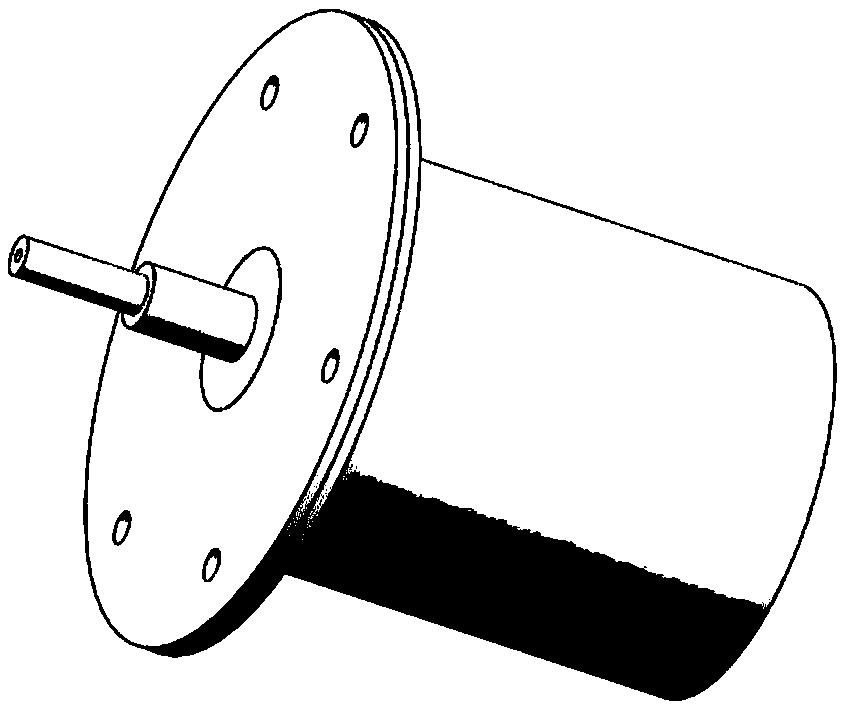

[0016] combined with Figure 1 to Figure 3 Describe the specific implementation of the present invention: the present invention can improve the thrust resolution and working medium utilization rate of the tangential field plasma thruster, the tangential field plasma thruster is an axisymmetric structure as a whole, including the main anode 1, the first pad Sheet 2, cover plate 3, casing 4, first-stage permanent magnet 5, second spacer 6, second-stage permanent magnet 7, wall anode 8 and ceramic channel 9, the above-mentioned casing 4 is open at the top and is provided with a ring The outer edge of the cylindrical shell, the ceramic channel 9 is a cylindrical shell with a central through hole on the top, the main anode 1 is arranged at the central through hole of the ceramic channel 9; the ceramic channel 9 is set inside the shell 4, and the ceramic The bottom end of the channel 9 corresponds to the bottom end of the shell 4, the top of the ceramic channel 9 is located outside ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap