A tangential field plasma thruster that can improve thrust resolution and working fluid utilization

A plasma and resolution technology, applied in the direction of using plasma, thrust reversers, machines/engines, etc., can solve the problems such as the decline of discharge performance such as thruster discharge efficiency, and the inability to adjust resolution to meet drag-free control, etc. The effect of working medium utilization rate and discharge efficiency, improving working medium utilization rate and improving thrust resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

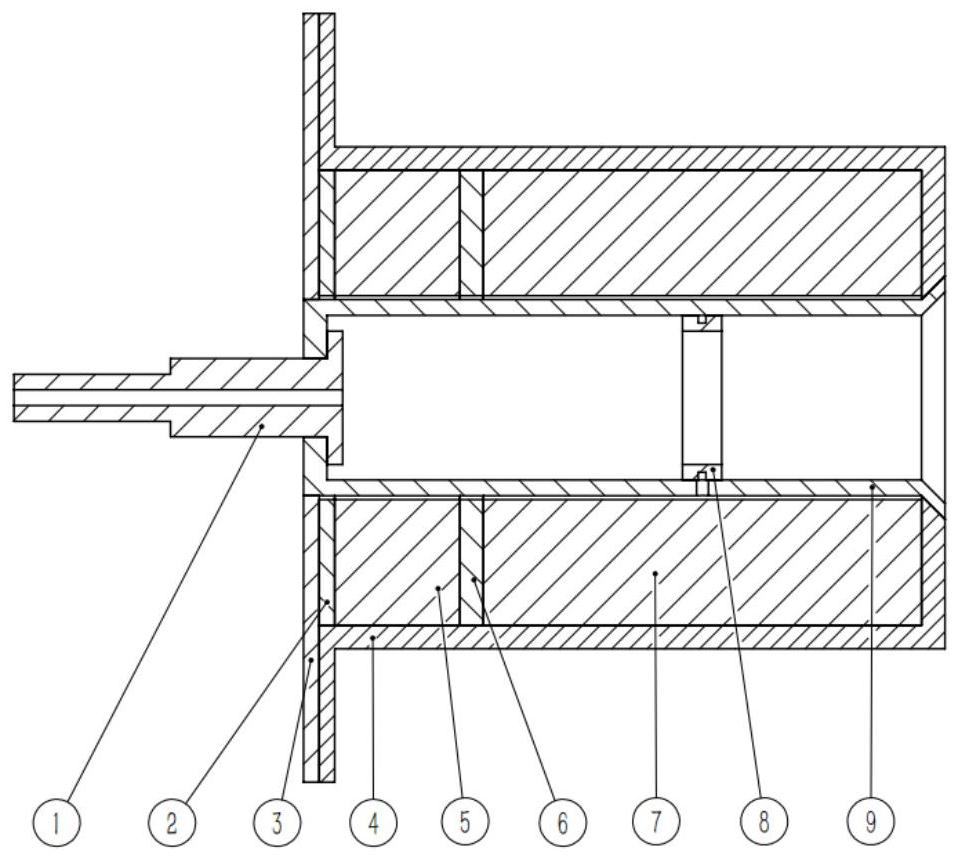

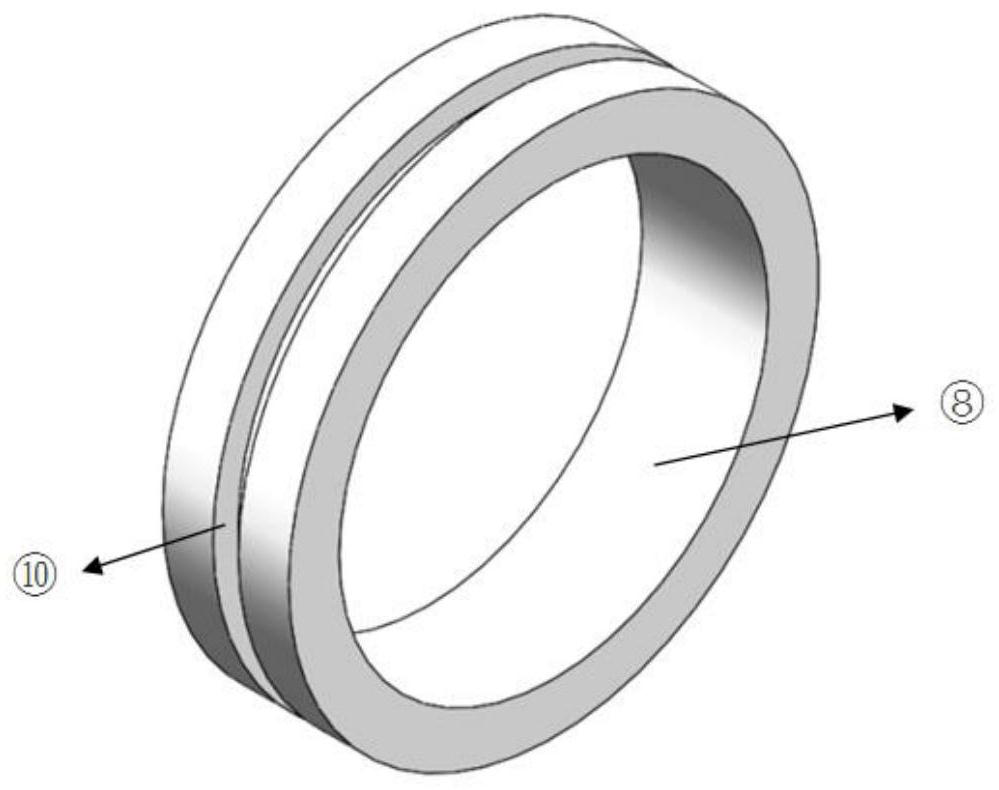

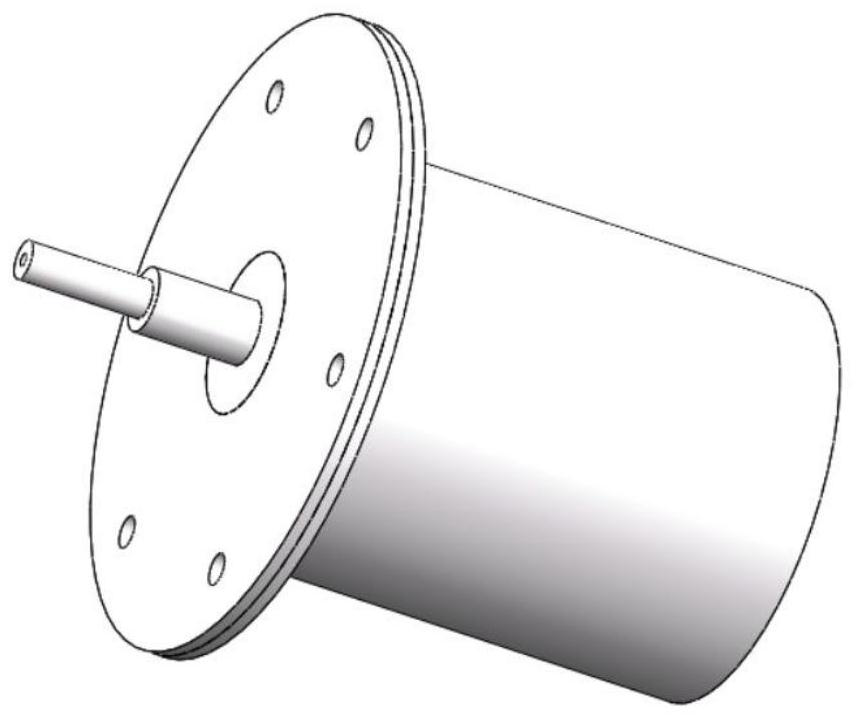

[0016] Join Figure 1 to 3 DETAILED DESCRIPTION OF THE INVENTION The present invention will be described that the present invention can improve the thrust resolution and working utilization rate, which will cut the field plasma thrust unit as a shaft symmetrical structure, including the primary anode 1, the first pad. The sheet 2, the cover plate 3, the outer casing 4, the first stage permanent magnet 5, the second spacer 6, the second permanent magnet 7, the wall anode 8, and the ceramic passage 9, the outer casing 4 is top opening and has a ring The cylindrical housing of the outer edge, the ceramic passage 9 is provided with a cylindrical housing having a central vias, and the main anode 1 is disposed at the center of the ceramic channel 9; the ceramic channel 9 is set inside the outer casing 4, ceramics The bottom end of the passage 9 corresponds to the bottom end of the outer casing 4, and the top end of the ceramic passage 9 is located outside the top of the outer casing 4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com