Bullet primer assembly depth line structured light measurement method

A line-structured light and measurement method technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high-precision extraction of the center of the light strip, affecting the accuracy and stability of the measurement accuracy and stability of the depth of the primer of the bullet, to reduce the calculation time, Solve the effect of reducing measurement accuracy and stability and solving cumulative errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, formulas and embodiments.

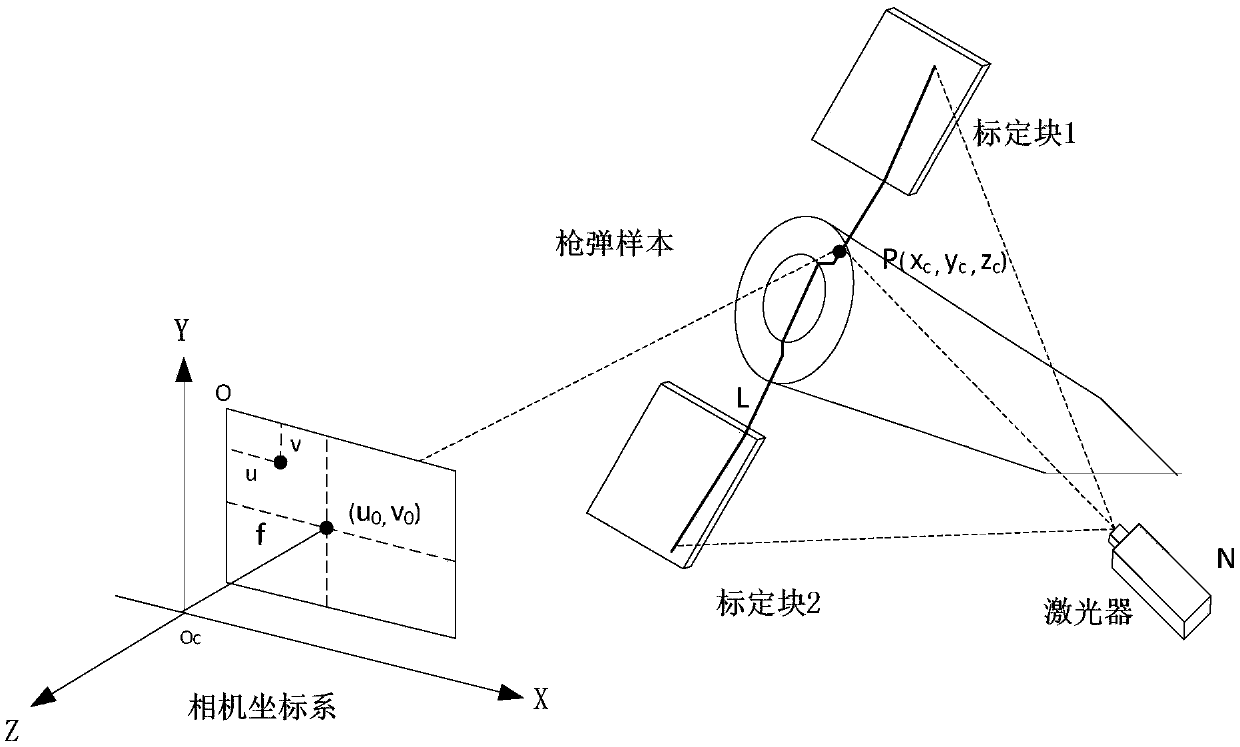

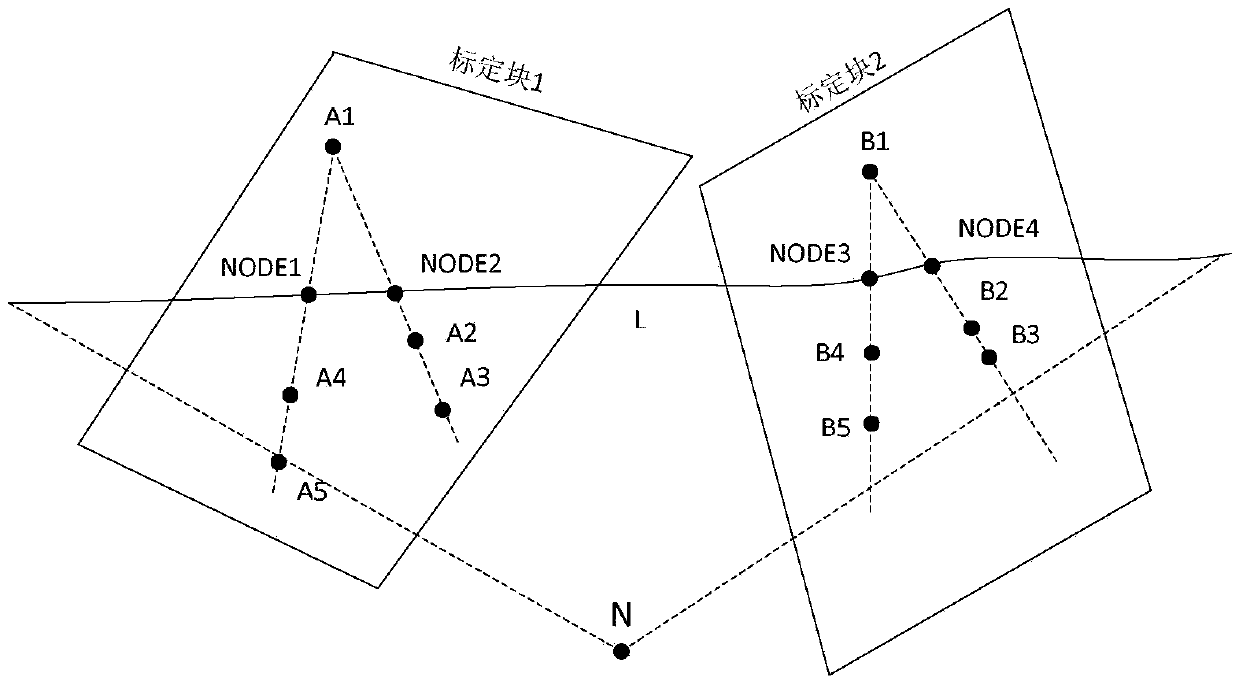

[0045] The existing linear structured light measurement and calibration methods cannot meet the needs of the bullet production line to quickly and accurately measure the assembly depth of the primer of the bullet. The invention provides a line-structured light measurement method for the assembly depth of the primer of the bullet, including a measurement model for the assembly depth of the primer of the bullet, a calibration method, and a method for extracting the center of the laser speckle light bar. In the measurement model, under the camera coordinate system, two calibration blocks are introduced for the calibration of structured light parameters, and straight line fitting is performed on multiple special points on the calibration blocks. In the camera coordinate system, calculate the intersection point of the line and the laser c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com