Novel self-balancing vertical loading test device

A technology of vertical loading and test device, which is applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., to save space and cost, avoid overturning damage, and facilitate installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical problems to be solved in the present invention, technical solutions and advantages clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments:

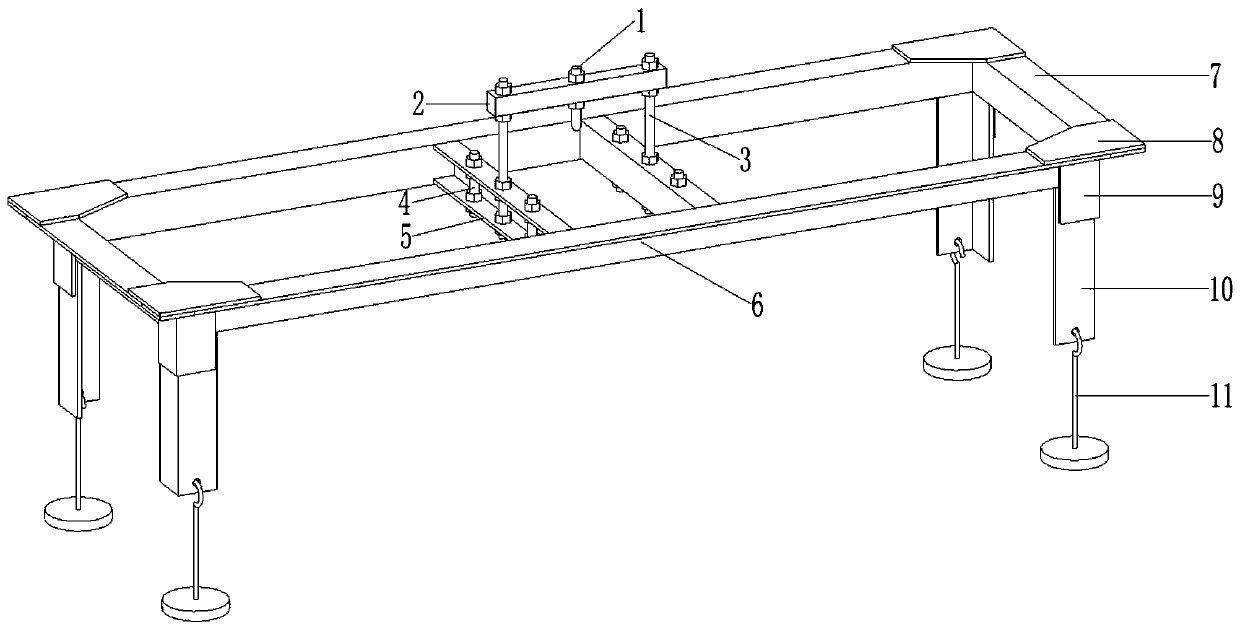

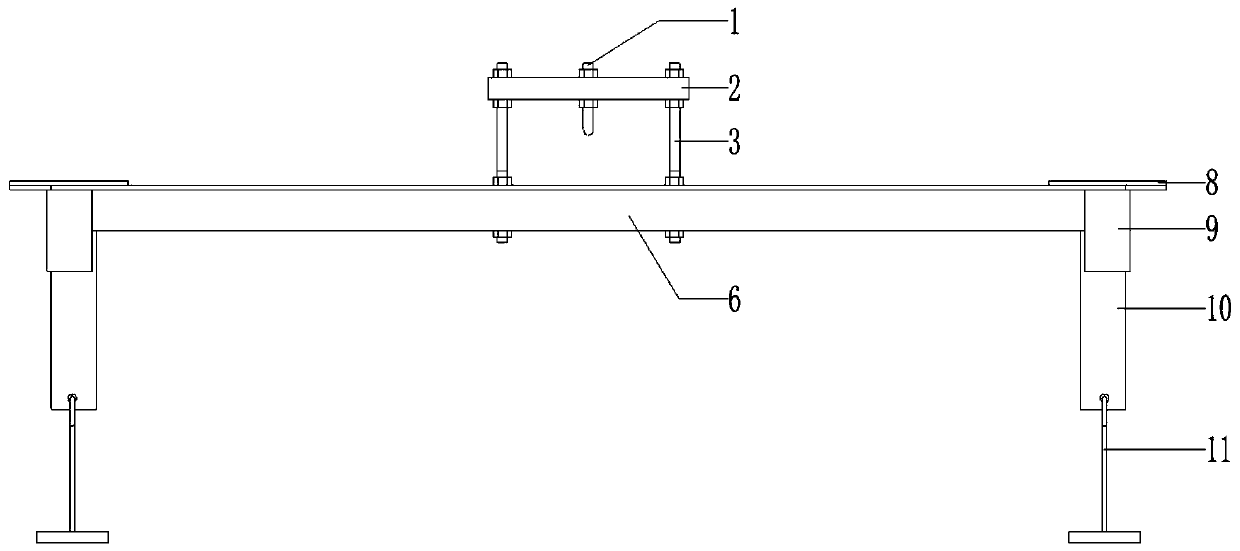

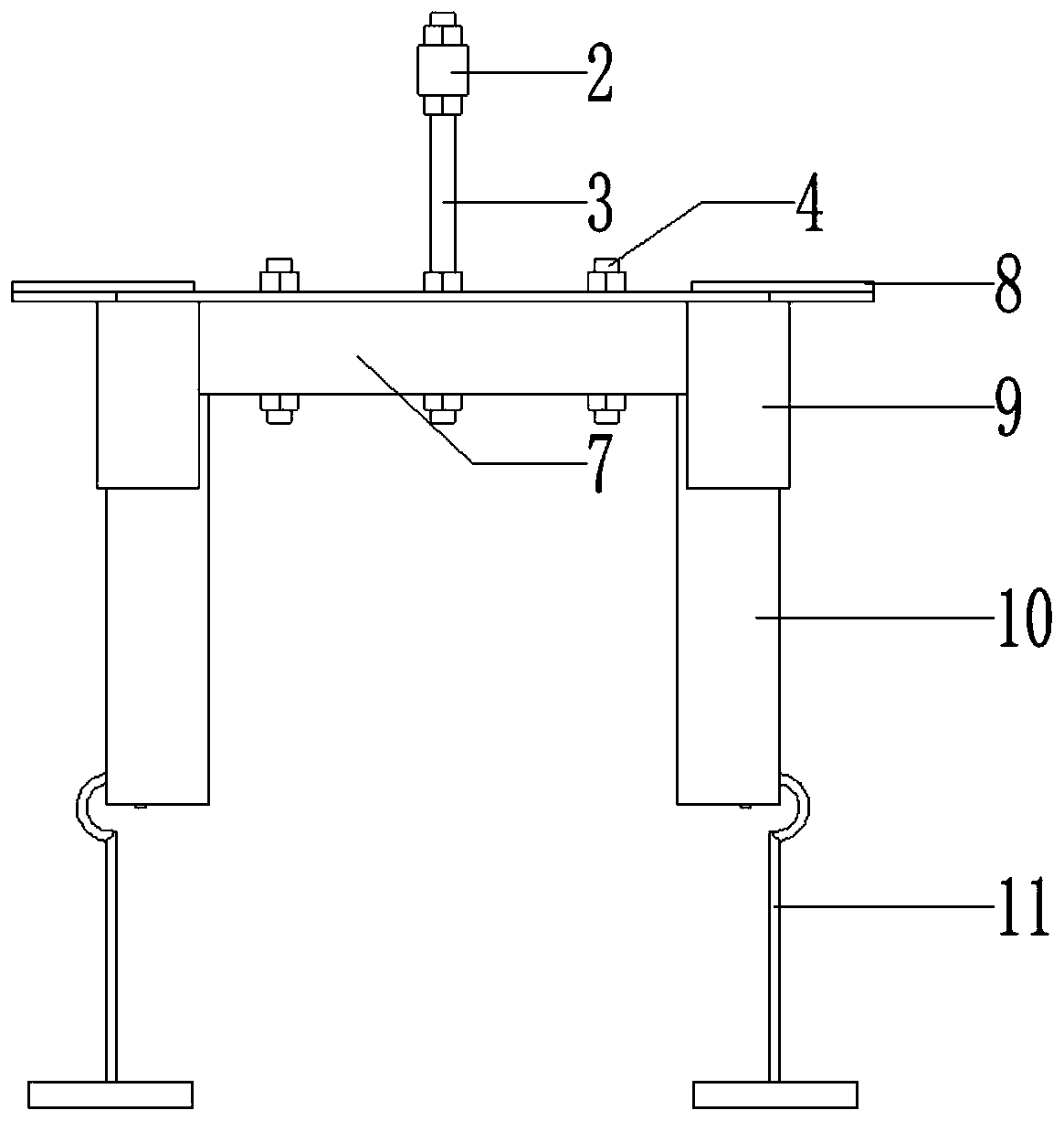

[0028] Such as Figure 1 to Figure 6 As shown, the self-balancing vertical loading test device of the present invention includes a short screw 1, a force transmission beam 2, two force transmission screws 3, four reinforcement screws 4, two channel steels 5, two long angle steels 6, two One short angle steel 7, four trapezoidal reinforced steel plates 8, four reinforced angle steels 9, four vertical angle steels 10 and four weight hooks 11.

[0029] The above-mentioned force transmission beam 2 is arranged horizontally and has vertical round holes in the middle and both sides; the above-mentioned short screw rod 1 passes through the middle hole, and is fixed with a nut after adjusting its position; the above-mentioned two force tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com