Organic Rankine cycle steam turbine generator unit cooling system adopting ejector

A technology of turbogenerator set and Rankine cycle, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve problems such as the inability to integrate the cooling of turbogenerator sets, achieve cost and space saving, easy maintenance and replacement, The effect of improving power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

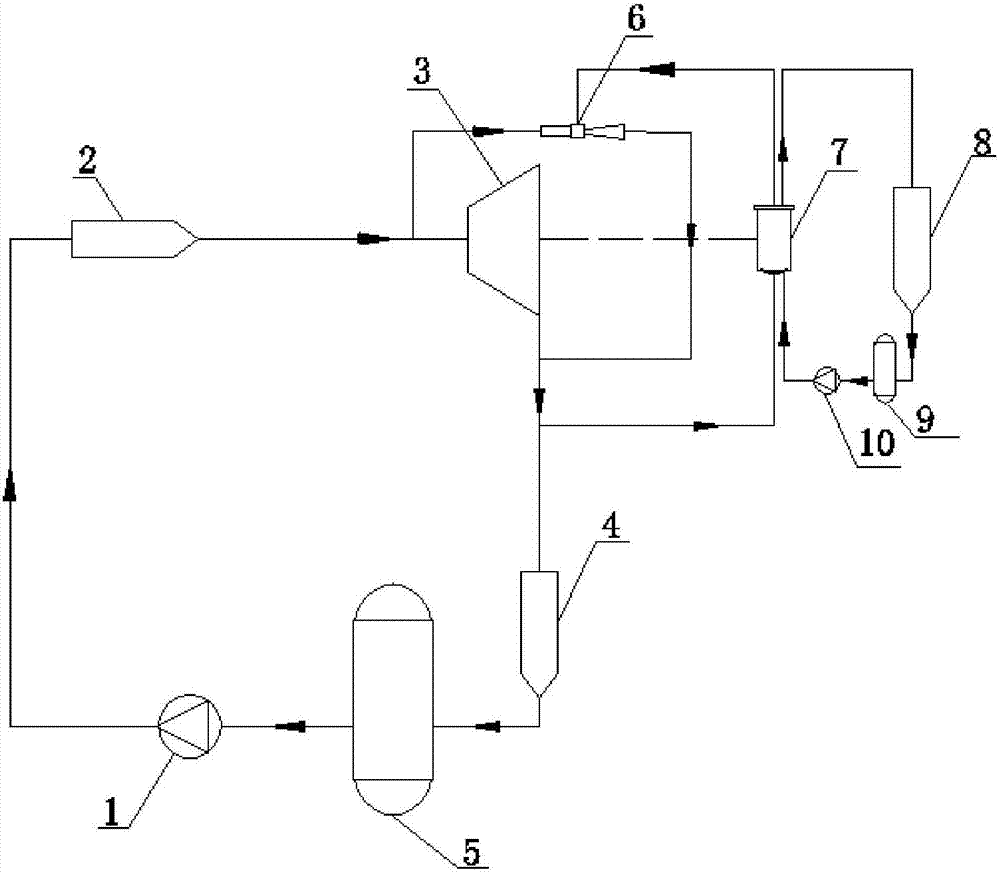

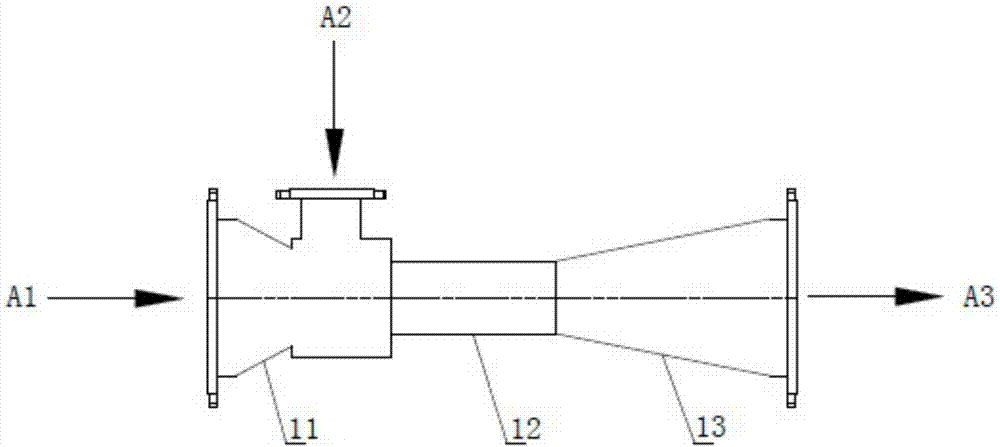

[0016] like figure 1 As shown, a cooling system of an organic rankine cycle turbogenerator set using an ejector of the present invention includes an organic rankine cycle power generation system and a cooling system, and the cooling system is used for cooling the organic rankine cycle power generation system Generator 7 is cooled; Organic Rankine cycle power generation system comprises working medium pump 1, evaporator 2, turbine 3, condenser 4, liquid storage tank 5 and generator 7, described working medium pump 1, evaporator 2, The turbine 3, the condenser 4, and the liquid storage tank 5 are connected in series by metal pipes in sequence to form an organic working fluid circulation loop, and the generator 7 is coaxially connected with the turbine 3.

[0017] The cooling system includes a water cooling circuit of the generator set and a gaseous organic working medium cooling circuit of the generator set, and the water cooling circuit of the generator set includes a cooler 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com