Device for twisting and disassembling steel wire rope or steel strand

A steel strand and steel wire rope technology, applied in the field of regeneration, can solve the problems of high energy consumption, low efficiency, and inability to realize continuous splitting, etc., and achieve the effect of reliable function, simple structure, and improved splitting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

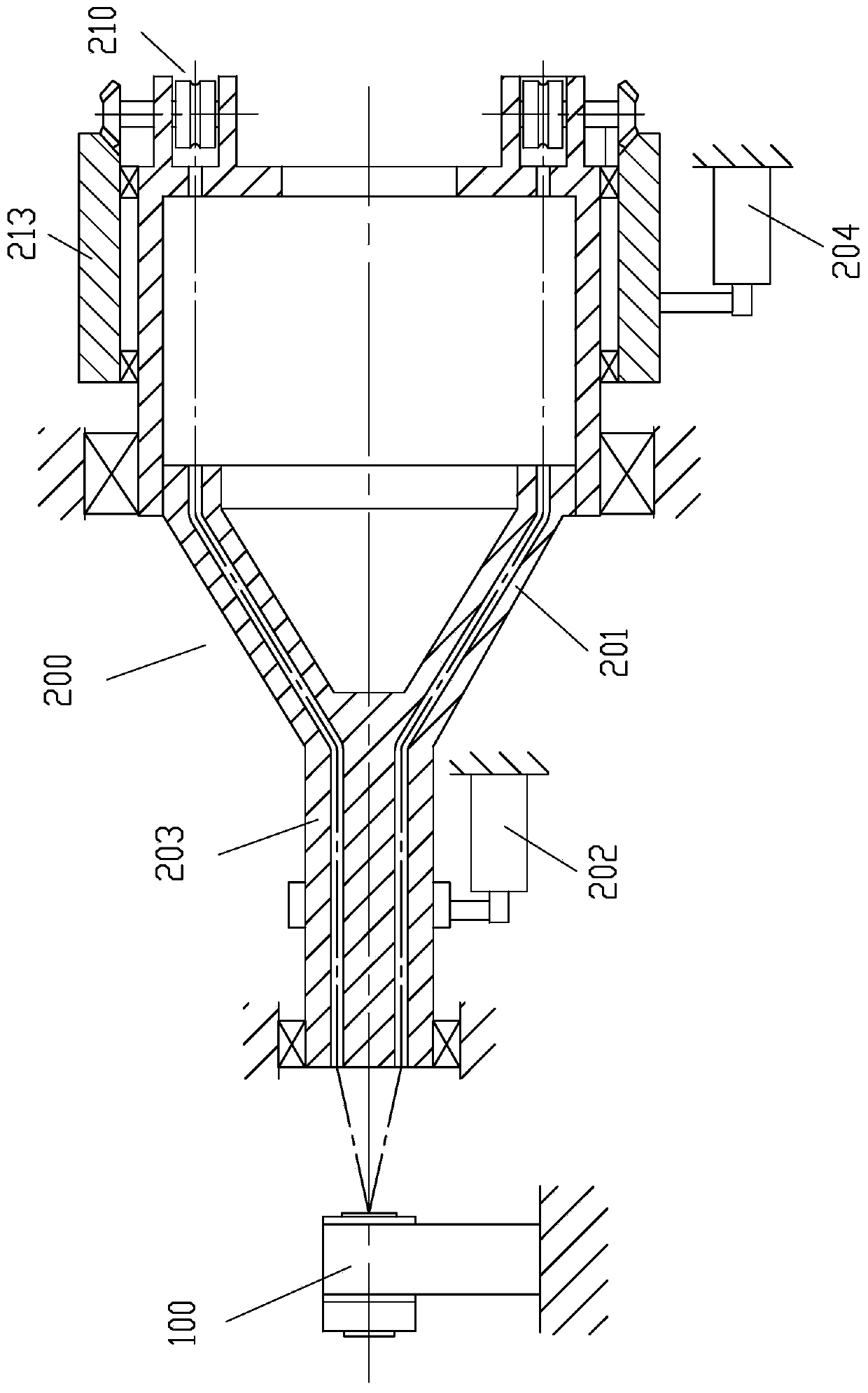

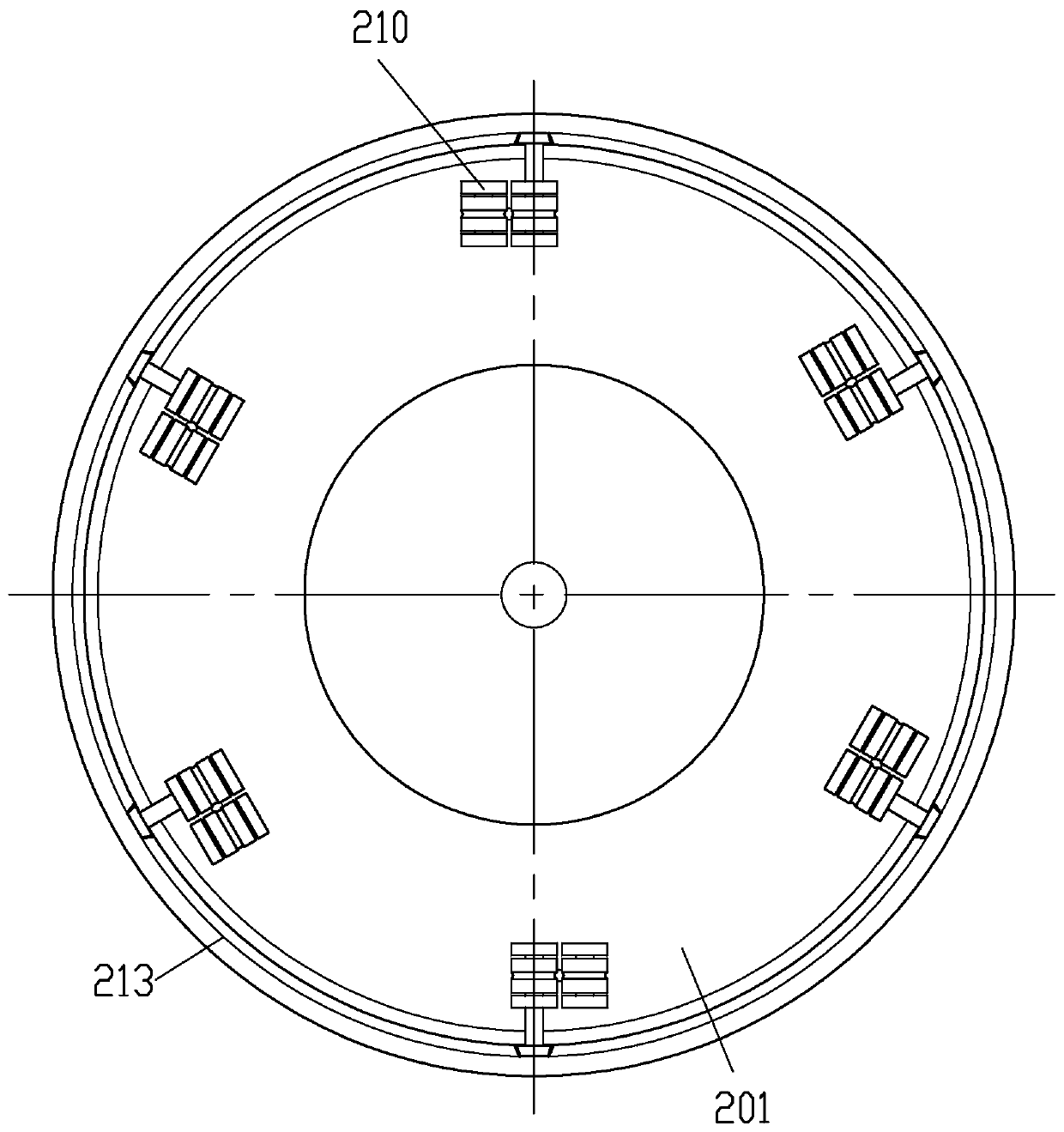

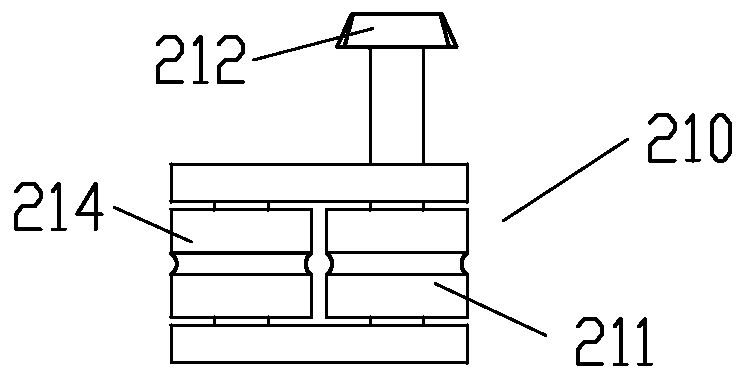

[0025] Example 1, see figure 1 , figure 2 , image 3 , a device for twisting and splitting steel wire ropes or steel strands, including a guiding device 100 and a splitting device 200, the guiding cylinder provided with the guiding device 100 can rotate intermittently, so as to split the steel wire rope or steel strand passing through the guiding cylinder while twisting When passing through the section, the steel wire rope or steel strand is prevented from twisting at the exit of the guide cylinder; the dismantling device 200 is a turntable structure capable of rotating in the direction of dismantling each strand of the steel rope or each steel wire of the steel strand, and on the turntable body 201 There are multiple steel wire traction mechanisms for pulling steel wire strands or steel wires.

[0026] Wherein, the guide hole wall in the guide cylinder is provided with spirally distributed protrusions, the guide cylinder is rotatably arranged on the base 1, and the guide c...

Embodiment 2

[0031] Example 2, see Image 6 , the sun gear is made up of a sun gear 213a, the sun gear 213a is connected with the second rotary drive source 204, and the sun gear 213a is rotatably arranged on the third fixed member of the frame class.

[0032] The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0033] Example 3, see Figure 7 , the brake device also includes an elastic element 8; the elastic force of the elastic element 8 and the electromagnetic force of the electromagnetic coil 4 coordinate and cooperate to form the braking and release of the brake on the guide cylinder. Wherein, braking device also comprises braking ring 5, and the through hole in the middle part of braking ring 5 can pass through freely for steel wire rope, and braking ring 5 is only movable and is coaxially arranged at one end of guide tube, and braking ring 5 is formed by described The elastic force of the elastic element 8 and the electromagnetic force of the electromagnetic coil 4 drive the movement; a jaw clutch structure is formed between the outer cylinder 3 of the guide cylinder and the brake ring 5; the elastic force of the elastic element 8 pushes the jaw clutch Combining to form a brake on the guide cylinder, the electromagnetic force generated after the electromagnetic coil 4 is energi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap