Battery deviation rectifying mechanism and battery conveying device

A technology of battery and deviation correction wheel, which is applied in transportation and packaging, conveyor objects, etc., can solve the problems of confusion of positive and negative poles of batteries, machine stuck, safety problems, etc. Pit, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

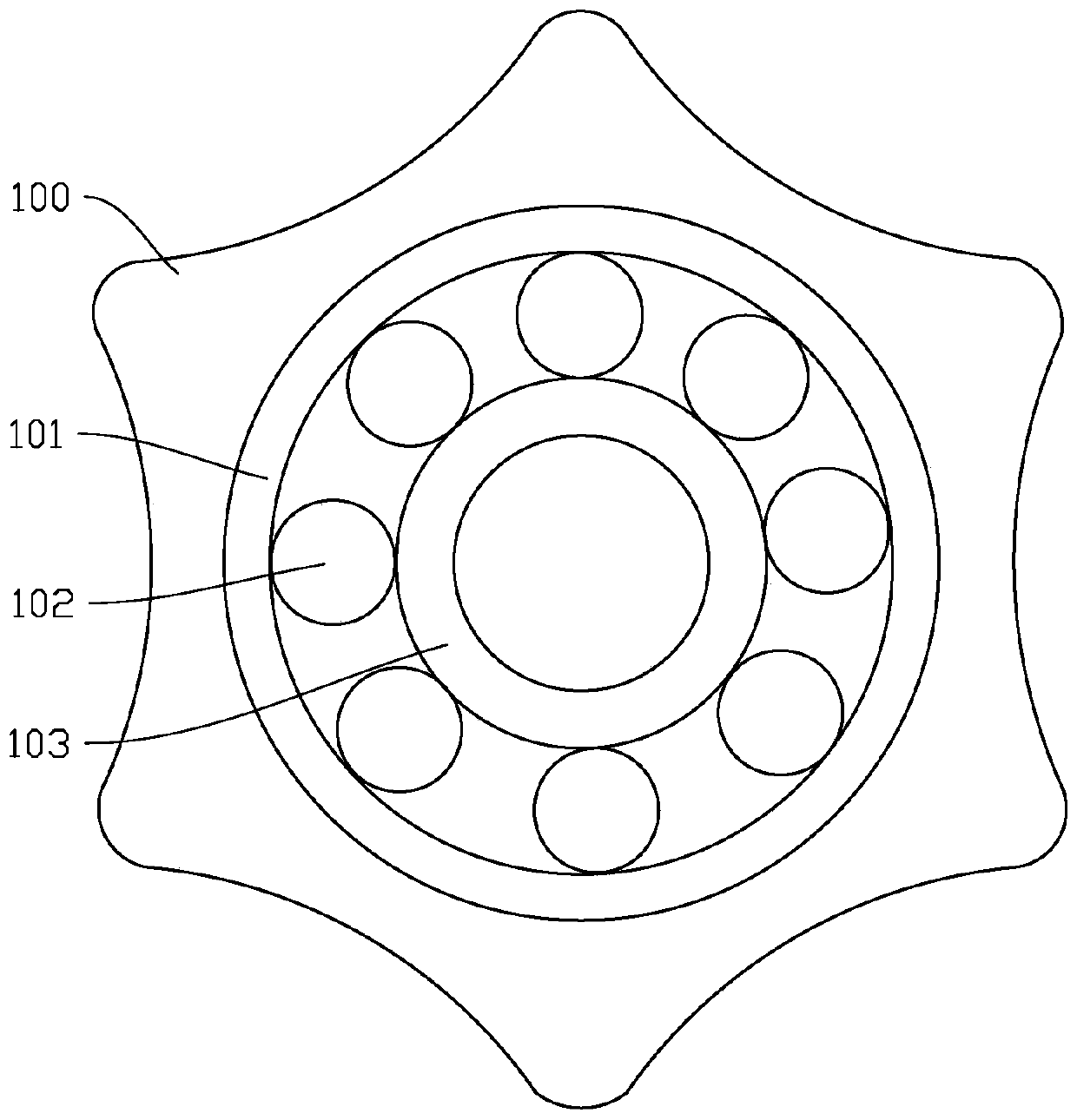

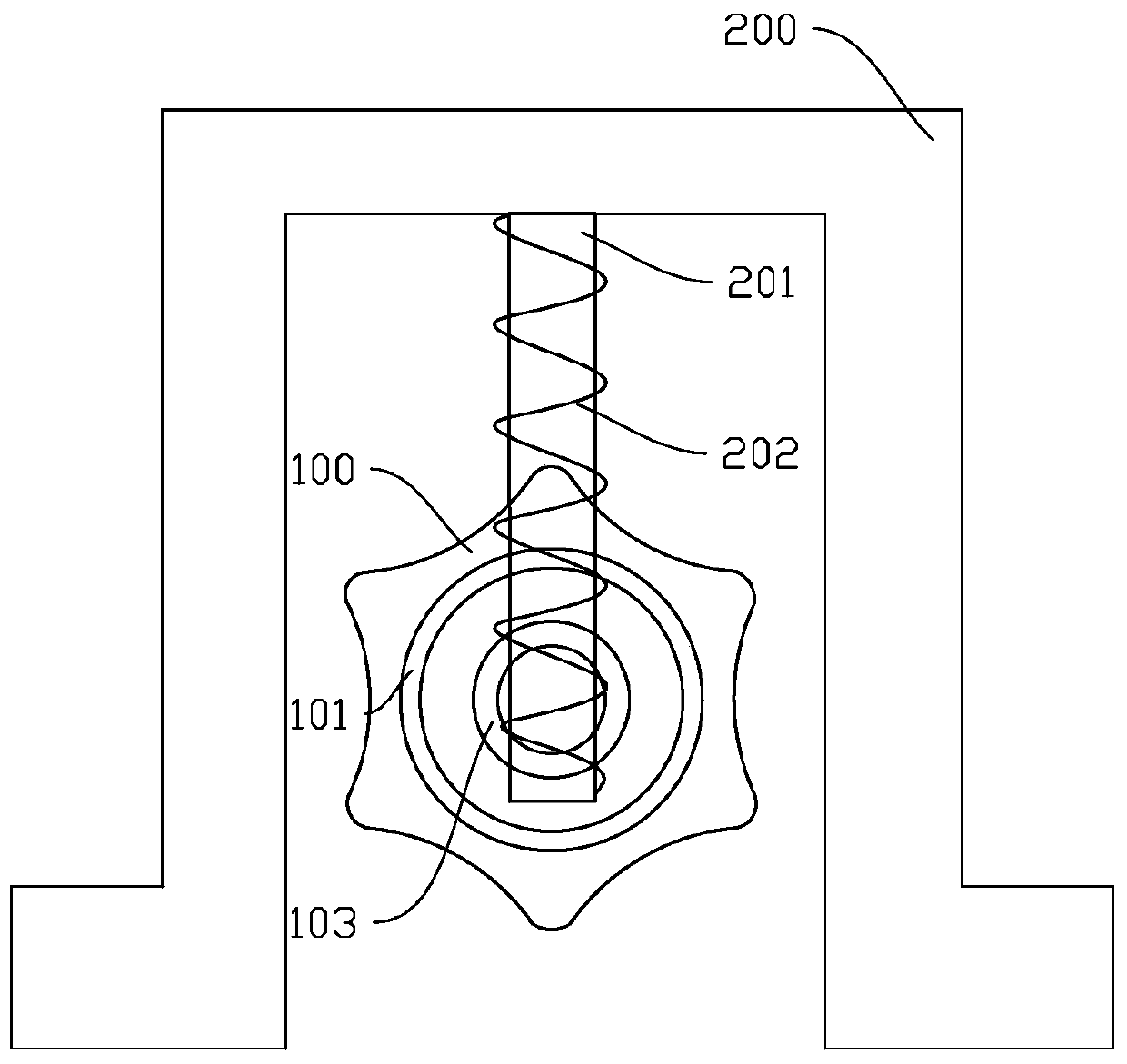

[0029] refer to figure 1 , showing a side view of a deviation correction wheel of a battery deviation correction mechanism. Such as figure 1 As shown, the deviation correction wheel includes an outer wheel body 100 , the wheel body 100 is sleeved on a bearing 101 , and the bearing 101 is further sleeved on a first shaft 103 . The outer surface of the wheel body 100 includes six arc surfaces adjacent to each other, and these six arc surfaces are recessed inward (that is, toward the direction of the first axis 103 ), and the axis direction of each arc surface is consistent with the direction of the first axis 103 Similarly, the radius of the arc surface is greater than or equal to the radius of the cylindrical battery to be corrected, so that the battery whose axis direction does not coincide with the axis direction of the arc surface will get stuck when passing through the wheel body 100 of the alignment wheel It cannot pass through the groove formed by the arc surface of the...

Embodiment 2

[0032] A battery deviation correction mechanism, the difference from Embodiment 1 is that a circlip is installed on the first shaft, and the circlip is opposed to the bearing, and the axial movement of the bearing can be constrained by the setting of the circlip.

Embodiment 3

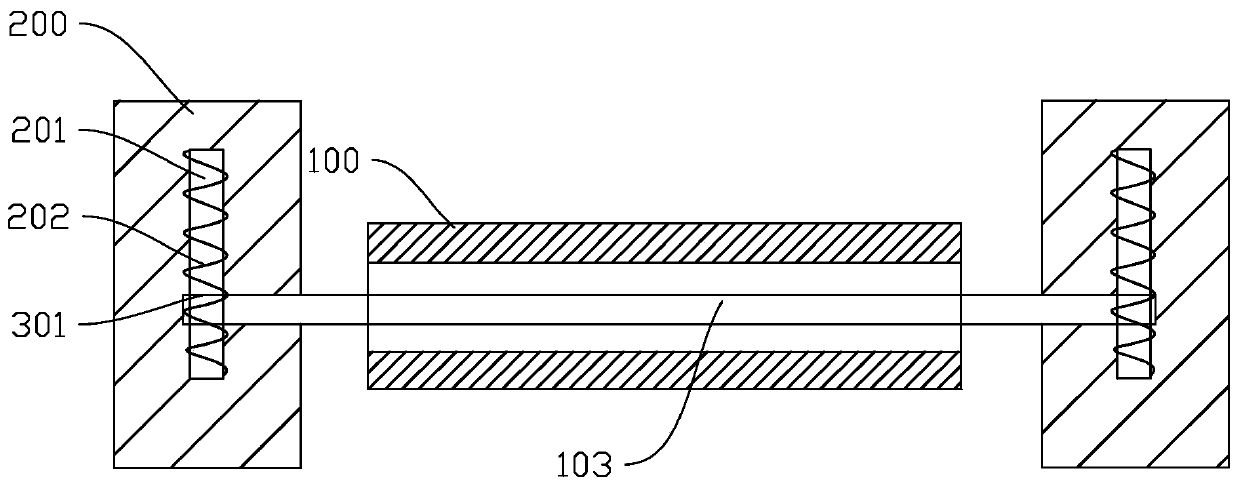

[0034] refer to Figure 4 , shows a partial cross-sectional schematic view of a battery deflection correction mechanism according to another embodiment of the present invention. As shown in the figure, the two ends of the second shaft 201 are thicker and the middle part is thinner, and the first shaft 103 is passed through the second shaft 201 In the middle, above and below the first shaft 103 are respectively provided several groups of springs 202 , one end of the spring 202 is fixed on the first shaft 103 , and the other end is fixed on the second shaft 201 . The relative position of the first shaft 103 and the second shaft 201 is adjusted by the spring 202 . When the interaction force between the correcting wheel and the battery is large, the upper spring is squeezed and shrinks upward, and the lower spring is stretched upward, thereby relieving the force between the correcting wheel and the battery and preventing the battery from being stuck inside the correcting wheel The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com