Water scabbling and recovery integrated machine

An all-in-one machine and chisel technology, which is applied in the direction of construction and building construction, can solve the problems of dust pollution to the environment and health hazards of construction workers, and achieve the effects of recycling, strong practicability, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

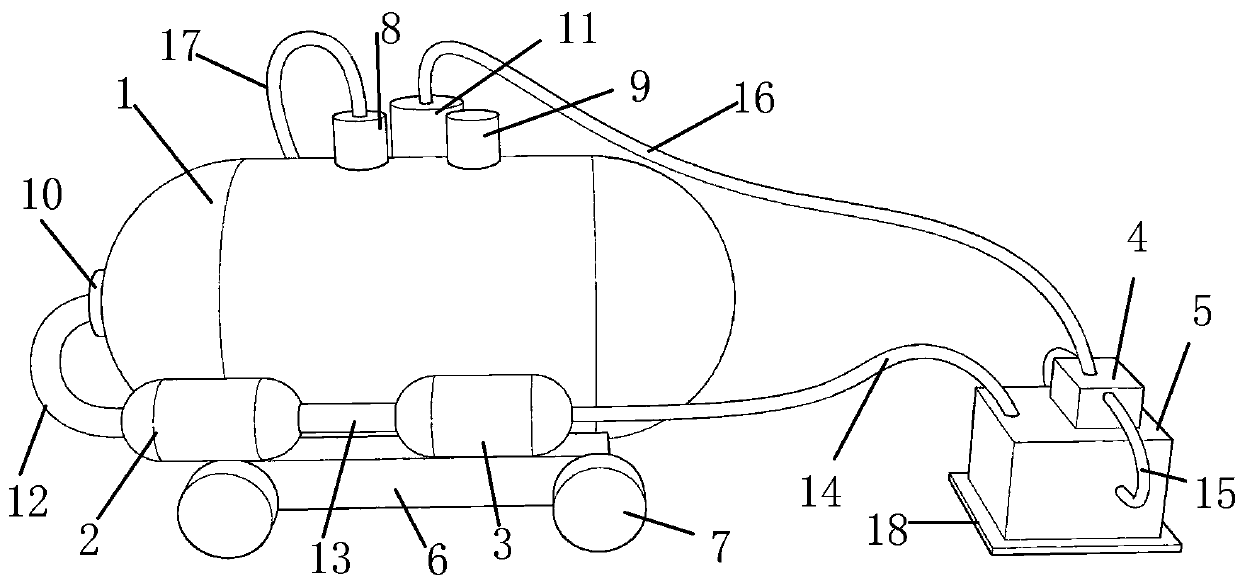

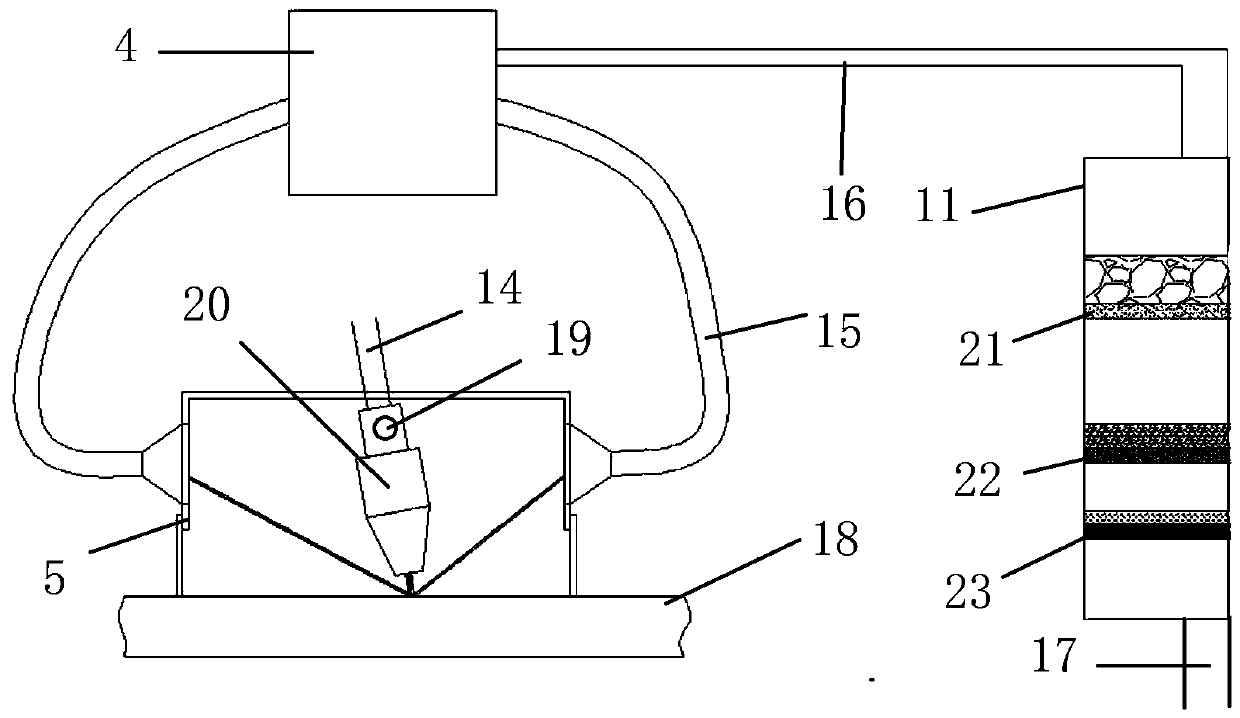

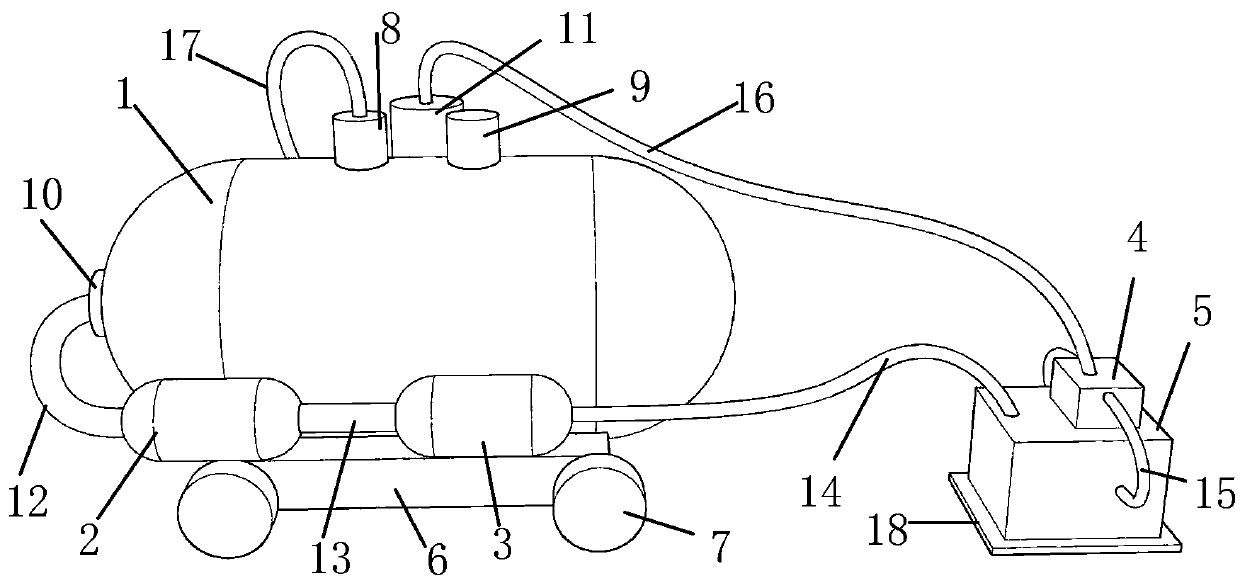

[0020] Such as Figure 1-2 Among them, a water chisel hair recovery integrated machine, including a chisel hair device, a recovery device, the chisel hair device includes a water supply device 1, a high-pressure water pump 2, an accumulator 3 and a nozzle 20, and the water supply device 1 is provided with There are a first water inlet 8, a second water inlet 9 and a water outlet 10, the water outlet 10 is connected to the high-pressure water pump 2 through the first conduit 12, the high-pressure water pump 2 is connected to the accumulator 3 through the second conduit 13, and the accumulator 3 The third conduit 14 is connected to the nozzle 20, and the nozzle 20 is provided with a control valve 19;

[0021] The recovery device includes a water retaining cover 5, a water absorber 4 and a storage tank 11, the water retaining cover 5 is set on the nozzle 20, the water absorber 4 is fixedly installed on the top of the water retaining cover 5, and the water absorber 4 and the retai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com