EGR valve with heating water cavity and heating method

A technology of EGR valve and heating water, which is applied to engine components, exhaust gas recirculation, machines/engines, etc. It can solve problems such as poor operation, adverse effects of the engine, less heat and heat dissipation, etc., to improve startup sticking and reduce condensation into ice risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

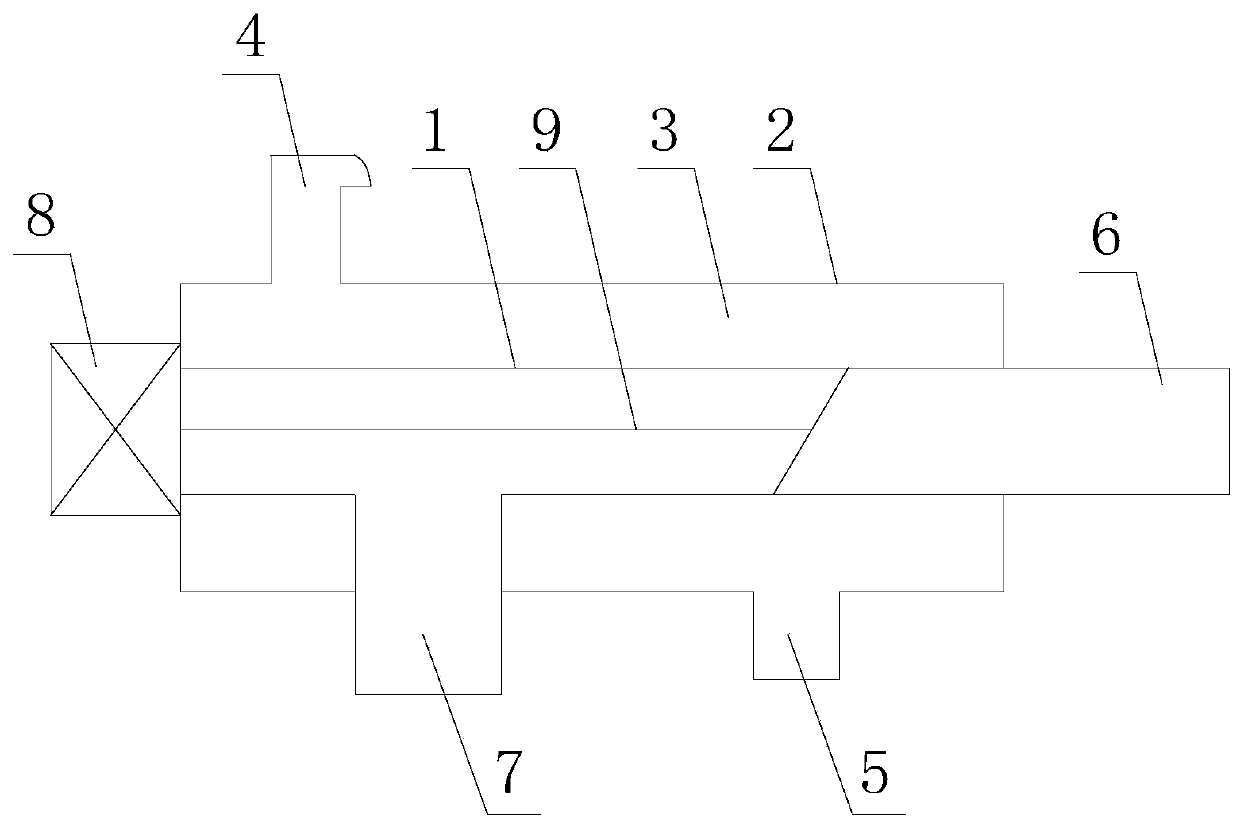

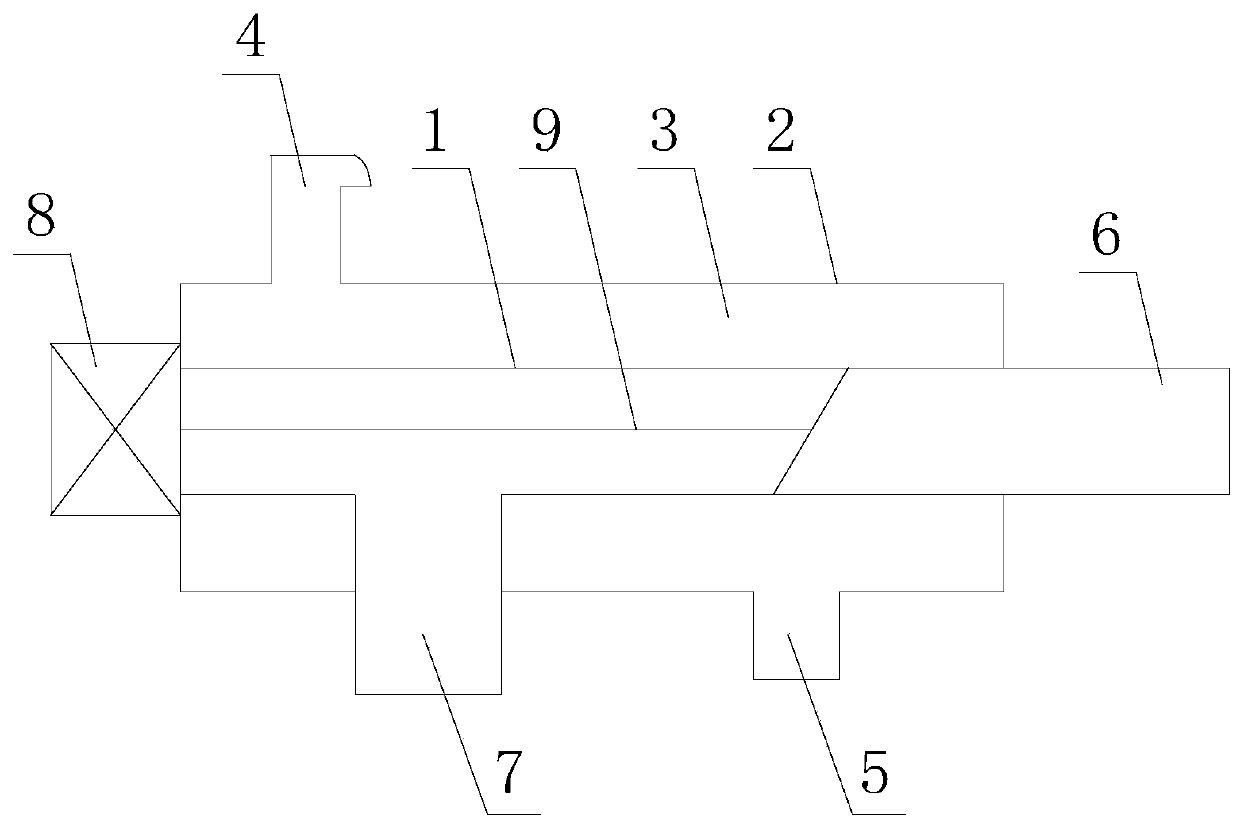

[0020] refer to figure 1 , an EGR valve with a heating water chamber, including a valve body 1, and a housing 2 wrapping the valve body 1, the gap between the valve body 1 and the housing 2 forms a heating water chamber 3, on the housing 2 A water inlet 4 and a water outlet 5 communicating with the heating water chamber 3 are provided. Through the water inlet 4 and the water outlet 5, circulating hot water can be introduced into the heating water chamber 3 to heat the valve body 1, so that the temperature of the EGR valve and valve seat is always above the freezing point, even if the engine is running with a small EGR rate load, it will not Icing on the EGR valve causes stagnation; at the same time, after the engine stops, the hot water retained in the heating water chamber 3 can continue to heat the residual water vapor in the EGR valve fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com