Air pressure water discharging device

A drainer and air pressure technology, which is applied in the direction of pressure pumps, machines/engines, gas/liquid distribution and storage, etc., can solve problems such as inability to complete drainage tasks, failure, and small price NPSH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

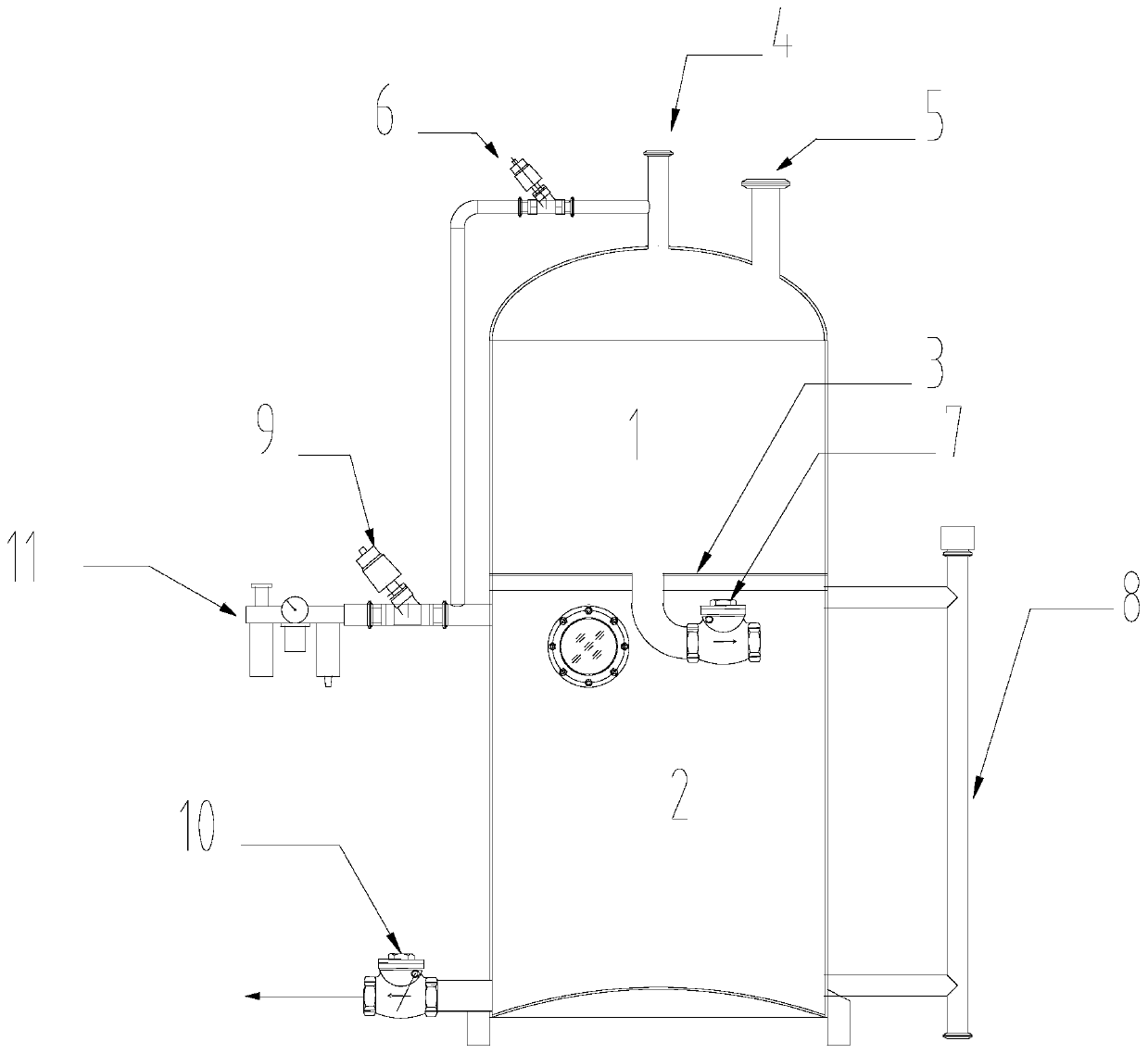

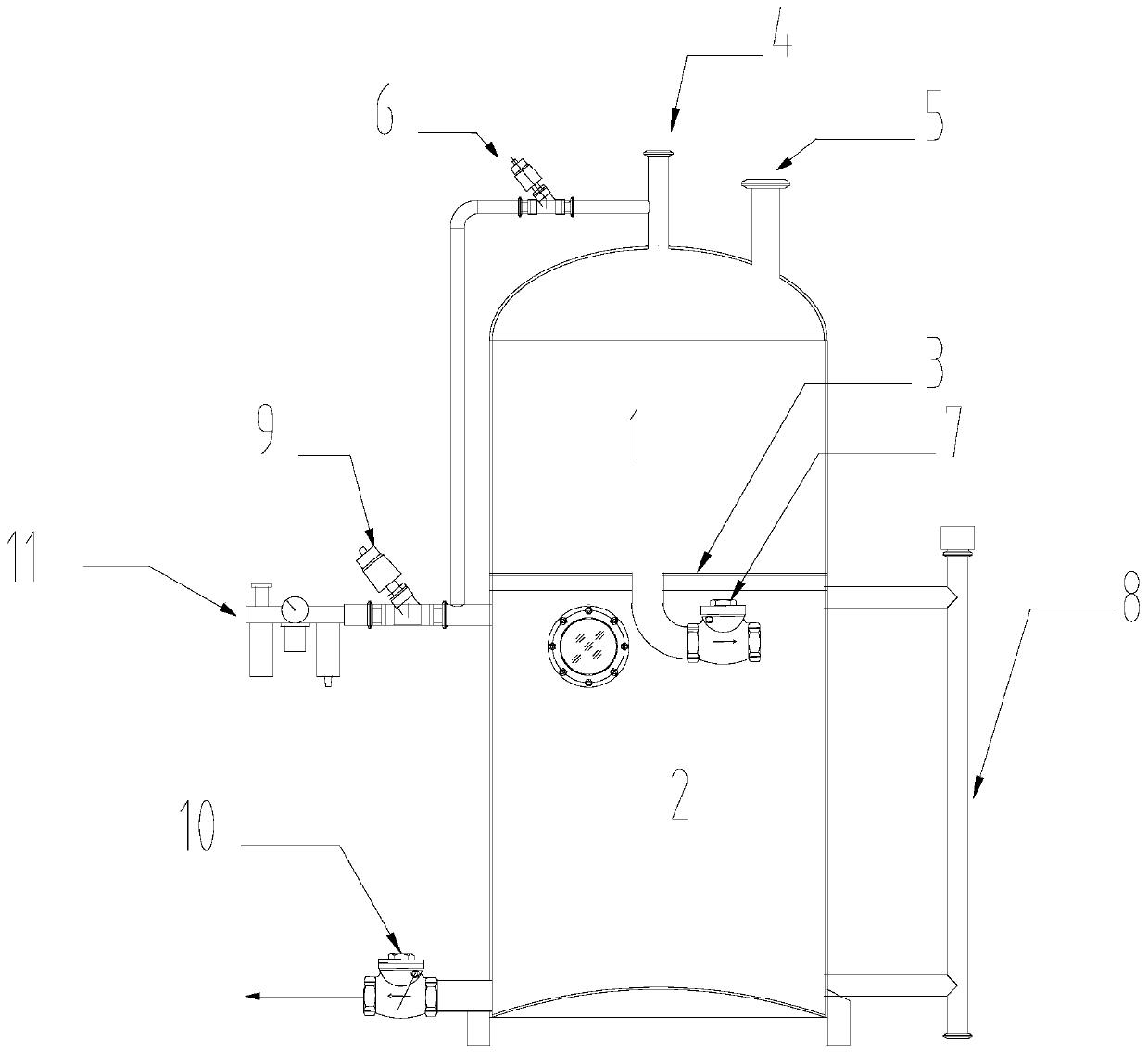

[0023] Such as figure 1 Shown is an air pressure automatic drainage device, which includes a water storage chamber, a drainage chamber and an air pressure automatic control part. The water storage chamber 1 and the drainage chamber 2 are separated into upper and lower layers by upper and lower chamber partitions 3 . The upper water storage chamber 1 is terminated with a vacuum port 4 connected to the system vacuum and a condensed water port 5 . The vacuum is connected with the lower drainage cavity 2 through the normally open vacuum valve 6, so that the lower drainage cavity 2 maintains a negative pressure before the water is full. Condensed water flows into the lower drainage chamber 2 through the normally open water storage check valve 7 installed in the center of the upper and lower chamber partitions 3 .

[0024] When the drainage chamber 2 is full of water, the water level controller 8 sends a water-full command, closes the vacuum valve 6, and opens the compressed air v...

Embodiment 2

[0027] Such as figure 1 The air pressure drain shown includes a cylinder body, and the inner chamber of the cylinder body is divided into an upper water storage chamber 1 and a drainage chamber 2 through an upper and lower chamber partition 3 in the middle, and a single unit is installed on the upper and lower chamber partition 3 To the water passing device; the outside of the cylinder is provided with a vacuum connecting pipe whose two ends are connected to the water storage chamber 1 and the drainage chamber 2 respectively.

[0028] The one-way water passing device includes a downwardly recessed water-guiding structure on the upper and lower chamber partitions 3 , and a water-storage one-way valve 7 is fixed at the free end of the water-guiding structure.

[0029] The upper part of the cylinder body is a convex dome structure, and the side of the dome structure is connected with a condensation water interface 5 .

[0030] A vacuum port 4 is communicated at the center of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com