Overhead transmission line inspection robot track system

A technology of overhead transmission lines and line inspection robots, which is applied in the direction of overhead lines/cable equipment, etc., can solve the problems of decreased inspection efficiency and the inability of line inspection robots to automatically cross over, etc., and achieve the effect of improving line inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above objects, features, and advantages of the present application, the present application will be further described in connection with the accompanying drawings and specific embodiments.

[0027] This application provides an overhead transmission line patrol robot rail system to solve existing cruisers that cannot automatically pass the corner towers, and need to use human aid to degrade the inspection efficiency.

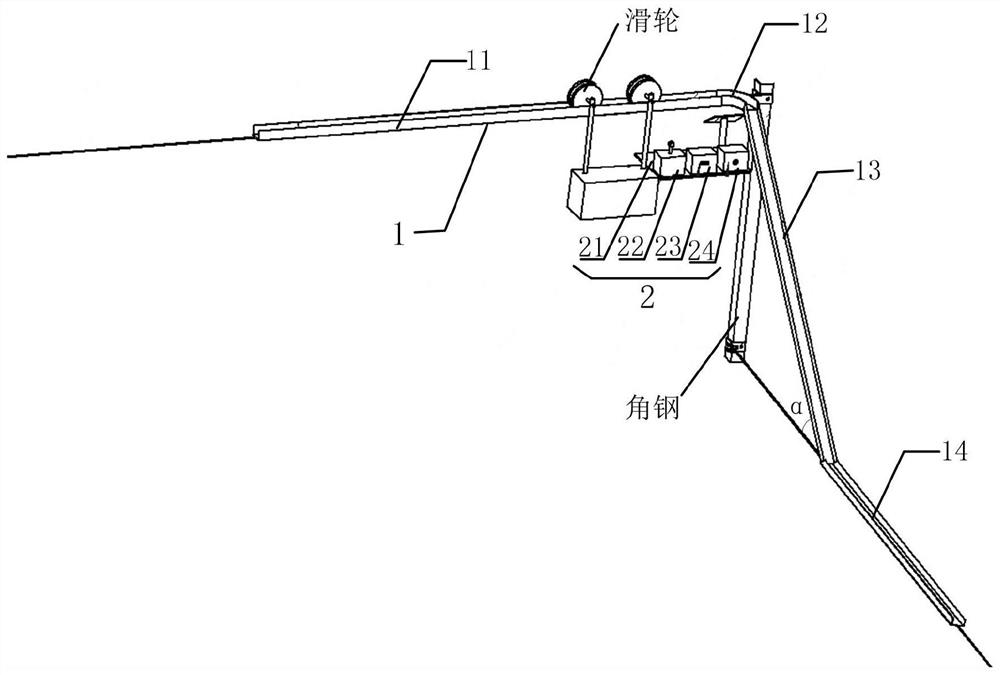

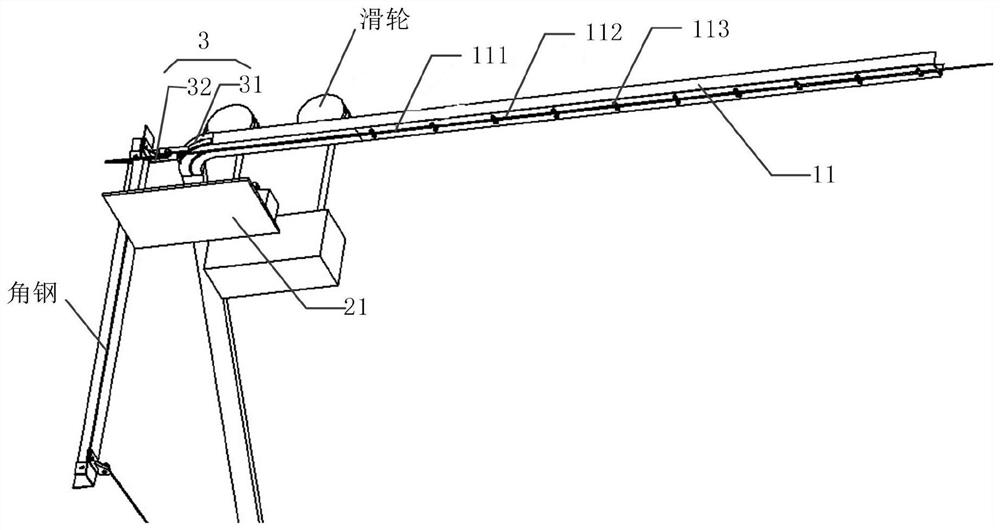

[0028] Refer figure 1 It is shown that an overhead transmission line patrol robot rail system includes: a transfusion rail 1 and auxiliary device 2;

[0029] The width of the transfer track 1 is provided according to the size of the pulley of the cruiser, and the pulley belongs to the motor mechanism of the cruiser, the motion mechanism to connect the cruiser body.

[0030] Generally, the cruist robot is composed of interconnected robot body and motion mechanism, which is composed of a pulley with a wire slot. When the cruiser is working, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com